A kind of composite reverse osmosis membrane based on water-soluble polymer and preparation method thereof

A water-soluble polymer, reverse osmosis membrane technology, used in reverse osmosis, semi-permeable membrane separation, general water supply conservation, etc. It needs to be further improved to achieve the effect of increasing water flux, improving pollution resistance and permeability, and reducing flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

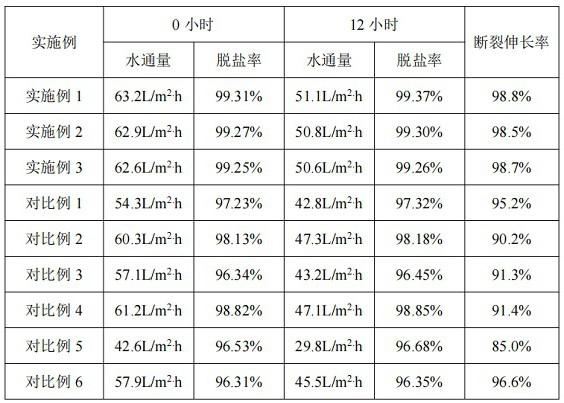

Examples

Embodiment 1

[0028] Step 1: (1) Mix 5 parts of m-phenylenediamine, 0.1 part of sodium dodecylbenzenesulfonate, 10 parts of thionyl chloride, 6 parts of glycerin, and 210 parts of deionized water to form a mixed solution, using 0.8wt% Camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=7.8 to obtain an aqueous phase solution; (2) Dissolving the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 24wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 2v / v% linoleic acid, set the temperature at 30°C and react for 4 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution and immerse for 1.5 minutes to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 2 minutes; place it in n-hexane extract solution for activation for 2 minutes; set the temperature to 80 ℃ drying for 5 minutes to obtain ...

Embodiment 2

[0031] Step 1: (1) Mix 4 parts of m-phenylenediamine, 0.08 parts of sodium dodecylbenzenesulfonate, 8 parts of thionyl chloride, 5 parts of glycerin, and 180 parts of deionized water to form a mixed solution, using 0.8wt% camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=7.2 to obtain an aqueous phase solution; (2) dissolve the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 20wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 1v / v% linoleic acid, set the temperature at 25°C and react for 2 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution and immerse for 1 minute to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 2 minutes; place it in n-hexane extract solution for activation for 1 minute; set the temperature to 75 ℃ drying for 5 minutes to obtain a pol...

Embodiment 3

[0034] Step 1: (1) Mix 6 parts of m-phenylenediamine, 0.12 parts of sodium dodecylbenzenesulfonate, 12 parts of thionyl chloride, 8 parts of glycerin, and 240 parts of deionized water to form a mixed solution, using 0.8wt% Camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=8.0 to obtain an aqueous phase solution; (2) Dissolving the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 25wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 3v / v% linoleic acid, set the temperature at 30°C and react for 4 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution for 2 minutes to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 3 minutes; place it in n-hexane extract solution for activation for 3 minutes; set the temperature to 82 ℃ drying for 8 minutes to obtain a polyamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com