Sintering process for preparing FeAl-NiO-Fe2O3 composite material metal ceramic inert anode

A feal-nio-fe2o3, inert anode technology, applied in the field of non-ferrous metal metallurgical molten salt electrolysis, can solve the problems of high cost and large pollution, and achieve the effect of good electrical conductivity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

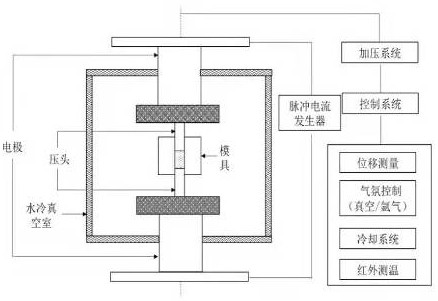

[0020] Ball mill Fe-Al metal powder for 48h, mix NiO and Fe 2 o 3 Ball milling for 6 hours, passing through a 60-mesh standard sieve for grinding and granulation, and forming by a hydraulic press with a forming pressure of 20 MPa. Put it into a spark plasma sintering furnace for sintering, set the temperature to 700°C, set the holding time to 6min, and adjust the pressure to 4Mpa. The schematic diagram of the spark plasma sintering furnace device is shown in figure 1 .

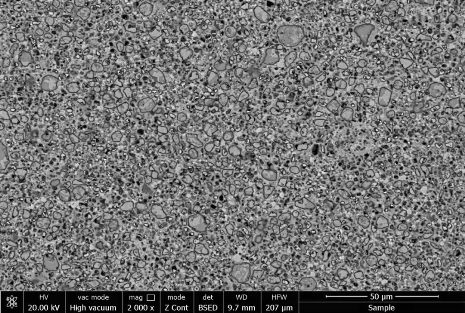

[0021] Observation of the sintered samples shows that the samples are well densified and there is no exposed metal phase aggregation phenomenon. The sintered samples 1#, 2#, and 3# were oxidized at 800°C for 25 hours under the same conditions, and the weight gain was 26.61mg / cm respectively. 2 、25.63mg / cm 2 、23.70mg / cm 2 .

[0022] Taking the average value, the weight gain of the cermet material is about 25.31mg / cm after the sample is subjected to 800°C for 25h 2 , After 25h, the weight gain of the samp...

Embodiment 2

[0024] Ball mill Fe-Al metal powder for 48h, mix NiO and Fe 2 o 3 Ball milling for 6 hours, passing through a 60-mesh standard sieve for grinding and granulation, and forming by a hydraulic press with a forming pressure of 20 MPa. Put it into a spark plasma sintering furnace for sintering, set the temperature to 750°C, set the holding time to 15min, and adjust the pressure to 4Mpa.

[0025] Observing the sintered sample under the same conditions will reveal that there will be metal deposition at the bottom of the sample, the metal phase will be exposed obviously, and the pores inside the sample will increase.

Embodiment 3

[0027] Ball mill Fe-Al metal powder for 48h, mix NiO and Fe 2 o 3 Ball milling for 6 hours, passing through a 60-mesh standard sieve for grinding and granulation, and forming by a hydraulic press with a forming pressure of 20 MPa. Put it into a spark plasma sintering furnace for sintering, set the temperature to 800°C, set the holding time to 20min, and adjust the pressure to 4Mpa.

[0028] Observing the sintered sample under the same conditions will reveal that the powder inside the sample is bonded, the metal phase is agglomerated, and the sintered product is not dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com