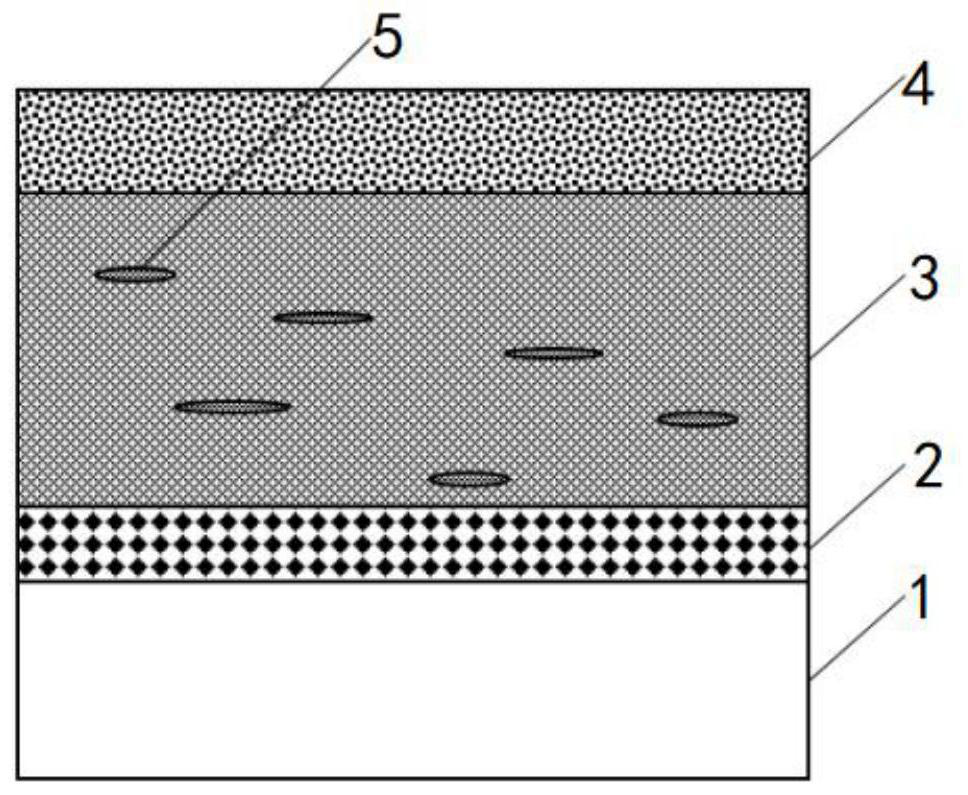

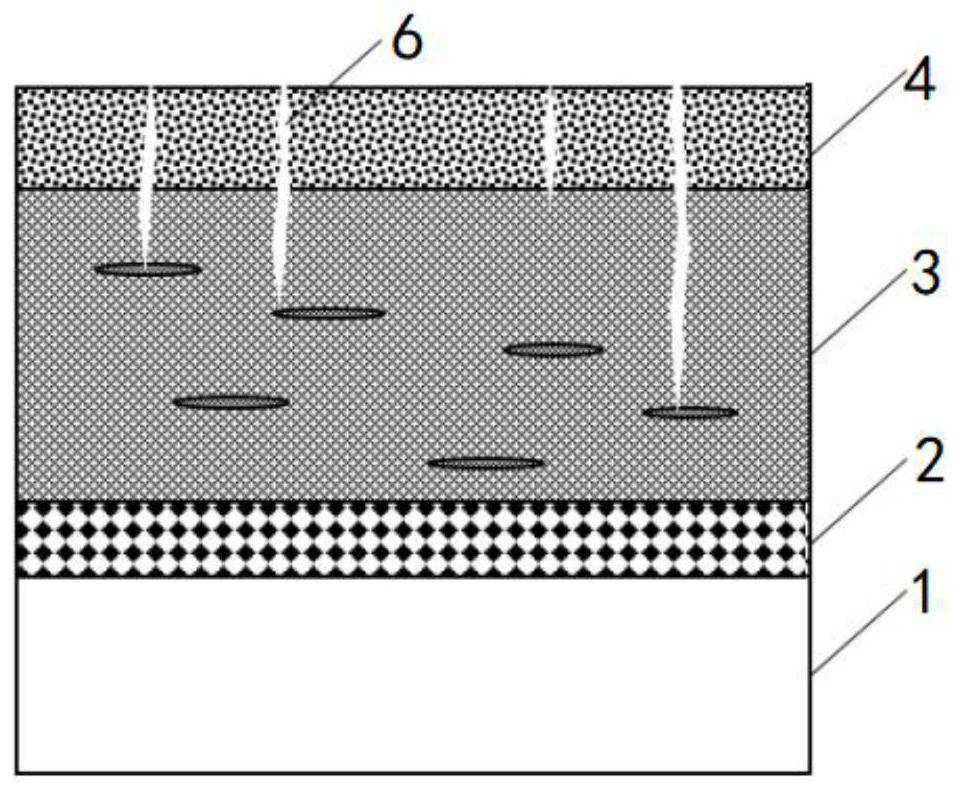

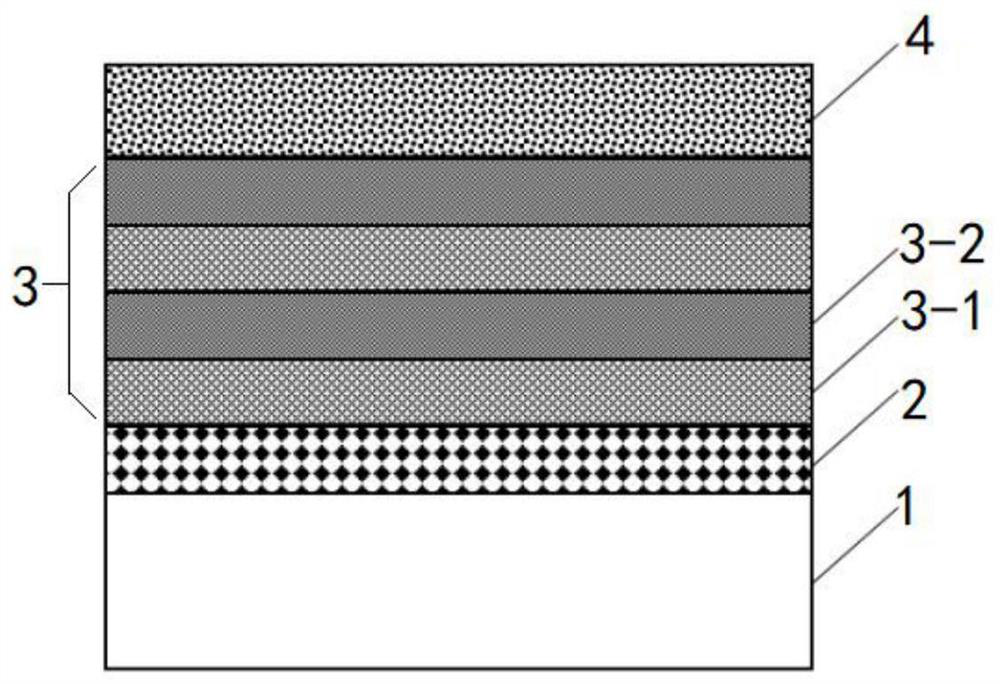

High-ductility metal pole plate pre-coating layer for reducing ion pollution of base material

A metal plate and ion pollution technology, applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of inapplicability to mass production and high cost, so as to improve ductility, corrosion resistance, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A highly ductile metal plate pre-coating that reduces ionic contamination of the base material is prepared on a roll-to-roll metal plate coating equipment with a long roll of sheet-shaped metal foil as the metal base material, and is prepared by the following steps:

[0039] (1) Vacuum the cleaning chamber to 8E-3Pa lower than the background vacuum, heat the temperature to 200°C, feed argon gas to maintain the chamber pressure at 0.1Pa, and apply a bias voltage of -800V to the sample for high bias plasma Cleaning to remove impurities and oxide films on the surface of metal substrates;

[0040] (2) Heat the temperature in the deposition chamber to 400°C, feed argon gas to maintain the chamber pressure at 0.1Pa, apply a bias voltage of -500V to the sample, and deposit metal Ti high-energy particles on the surface of the metal substrate by high-bias sputtering , the deposition time is 10min, and a high-energy bonding layer with a thickness of 6nm is obtained;

[0041] (3)...

Embodiment 2

[0046] A highly ductile metal plate pre-coating that reduces ionic contamination of the base material is prepared on a roll-to-roll metal plate coating equipment with a long roll of sheet-shaped metal foil as the metal base material, and is prepared by the following steps:

[0047] (1) Vacuum the cleaning chamber to 8E-3Pa lower than the background vacuum, heat the temperature to 250°C, feed argon gas to maintain the chamber pressure at 0.2Pa, and apply a bias voltage of -700V to the sample for high bias plasma Cleaning to remove impurities and oxide films on the surface of metal substrates;

[0048] (2) Heat the temperature in the deposition chamber to 400°C, feed argon gas to maintain the chamber pressure at 0.1Pa, apply a bias voltage of -500V to the sample, and deposit metal Nb high-energy particles on the surface of the metal substrate by high-bias sputtering , the deposition time is 20min, and a high-energy bonding layer with a thickness of 20nm is obtained;

[0049] (3...

Embodiment 3

[0054] A highly ductile metal plate pre-coating that reduces ionic contamination of the base material is prepared on a roll-to-roll metal plate coating equipment with a long roll of sheet-shaped metal foil as the metal base material, and is prepared by the following steps:

[0055] (1) Vacuum the cleaning chamber to 8E-3Pa lower than the background vacuum, heat the temperature to 200°C, feed argon gas to maintain the chamber pressure at 0.1Pa, and apply a bias voltage of -800V to the sample for high bias plasma Cleaning to remove impurities and oxide films on the surface of metal substrates;

[0056] (2) Heat the temperature in the deposition chamber to 200°C, feed argon gas to maintain the chamber pressure at 0.2Pa, use the ion implantation method to implant high-energy ions of metal Cr on the surface of the metal substrate, the implantation energy is 0.1MeV, and the implantation time is 60min. Obtain a high-energy bonding layer with a thickness of 30nm;

[0057] (3) Heat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com