Preparation method of sericite-doped expandable polystyrene composite beads

A technology of expandable polystyrene and polystyrene, which is applied in the field of new energy-saving materials, and can solve the problems of high probability of sticking to the kettle, unsatisfactory methods, and easy adhesion of doped sericite polystyrene composite beads , to avoid adhesion phenomenon, good social and economic benefits, and increase the viscosity of the composite system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

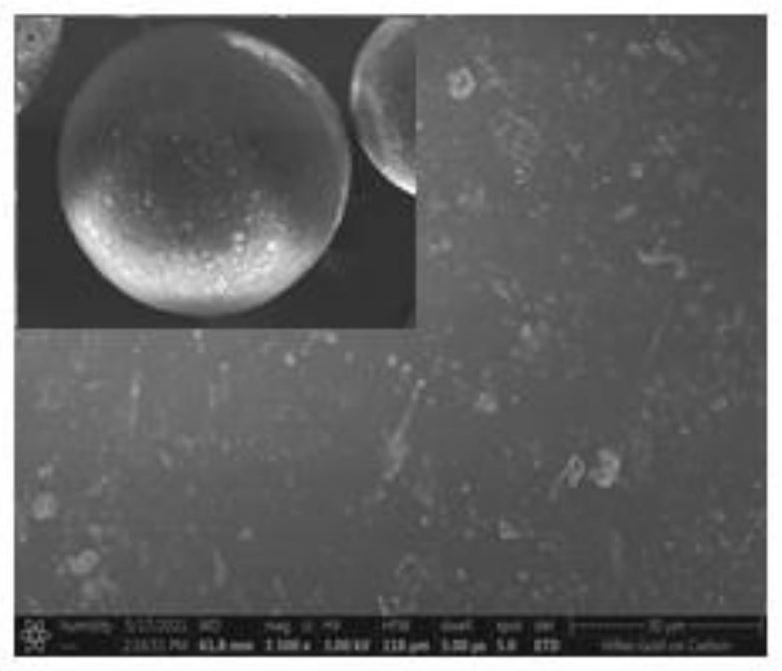

Image

Examples

preparation example Construction

[0037] The preparation method of the present invention doping sericite expandable polystyrene composite beads comprises the following steps:

[0038] Add a certain weight ratio of sericite, styrene monomer, initiator and other additives into the reaction kettle, stir to dissolve the initiator and other additives and evenly disperse the sericite in the styrene monomer, continue stirring, and pass The increase in the viscosity of styrene monomer is achieved as follows.

[0039] Specifically, the other additives include nucleating agents and flame retardants.

[0040] The initiator is benzoyl peroxide, or benzoyl peroxide and tert-butyl peroxybenzoate at a mass ratio of 1-5:1.

[0041] The mass ratio of the styrene monomer to the initiator is 100:0.1-2.

[0042] The sericite is a modified lipophilic sericite, and the surface of the sericite is made lipophilic by adding a surface modifying agent such as silane and titanate.

[0043] The mass ratio of styrene to polystyrene and ...

Embodiment 1

[0055] Add 10g Na to 500ml desalted water 2 SO 4 , 0.15 sodium dodecylsulfonate and 0.25 sodium carboxymethylcellulose were dissolved at 40°C to obtain a dispersant.

[0056] Weigh 10 g of sericite, 180 g of styrene (200 mL), 1.5 g of benzoyl peroxide, 3 g of hexabromocyclododecane, 0.37 g of tert-butyl peroxybenzoate, 0.35 g of DCP, and 0.38 g of nucleating agent in 1 In the elevated autoclave, stir at 500rpm under normal temperature and pressure, heat gradually to 83°C and start in-situ polymerization and measure the viscosity of the styrene phase. The viscosity of the styrene phase was measured at 100min as 48cP.

[0057] Keep the rotation speed at 500rpm, add 380mL of the above dispersant and stabilize it for 30min, then raise the temperature to 85°C and keep the temperature constant for 140min, check whether the particles sink and harden in normal temperature water, if sink and harden, add 1g calcium hydroxyphosphate powder and seal the kettle . Keep the rotating speed...

Embodiment 2

[0059] Weigh 9.9kg of modified sericite, 135kg of styrene, 1kg of benzoyl peroxide, 3kg of hexabromocyclododecane, 370g of tert-butyl peroxybenzoate, 350g of DCP, and 380g of nucleating agent in a 900L autoclave, Stir at 140 rpm under normal pressure, add 45 kg of polystyrene waste and stir until completely dissolved, at this time the viscosity of the styrene phase is 218 cP.

[0060] Keep the rotation speed at 140rpm, add 390L of dispersant (containing 0.8% sodium oleate, 0.01% hydroxymethyl cellulose, 1% Na 2 SO 4 , and 0.015% gelatin), and after stabilizing for 30 minutes, raise the temperature to 85°C and keep the temperature constant for 140 minutes, check whether the particles sink and harden in normal temperature water, if sink and harden, add 1kg calcium hydroxyphosphate powder and seal the kettle. Keep the rotational speed at 140 rpm, and heat up to 115° C. at a heating rate of 0.2° C. / min. Utilize the pressure balance feeding device to add pentane 16kg, add N 2 Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com