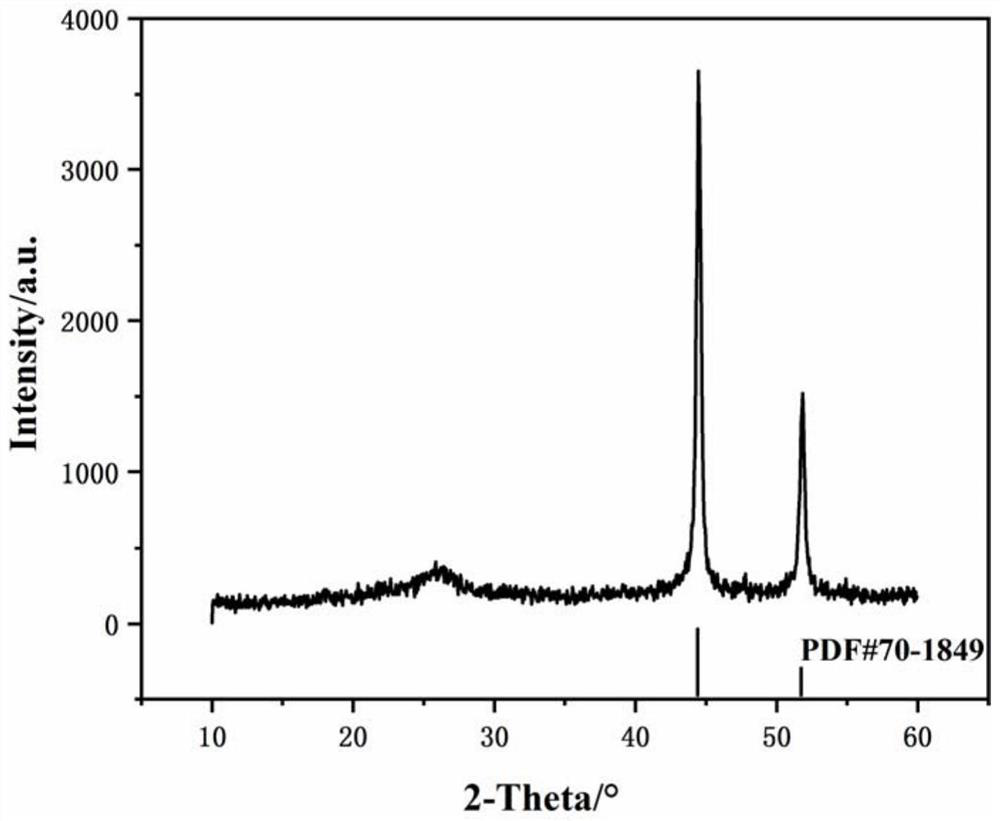

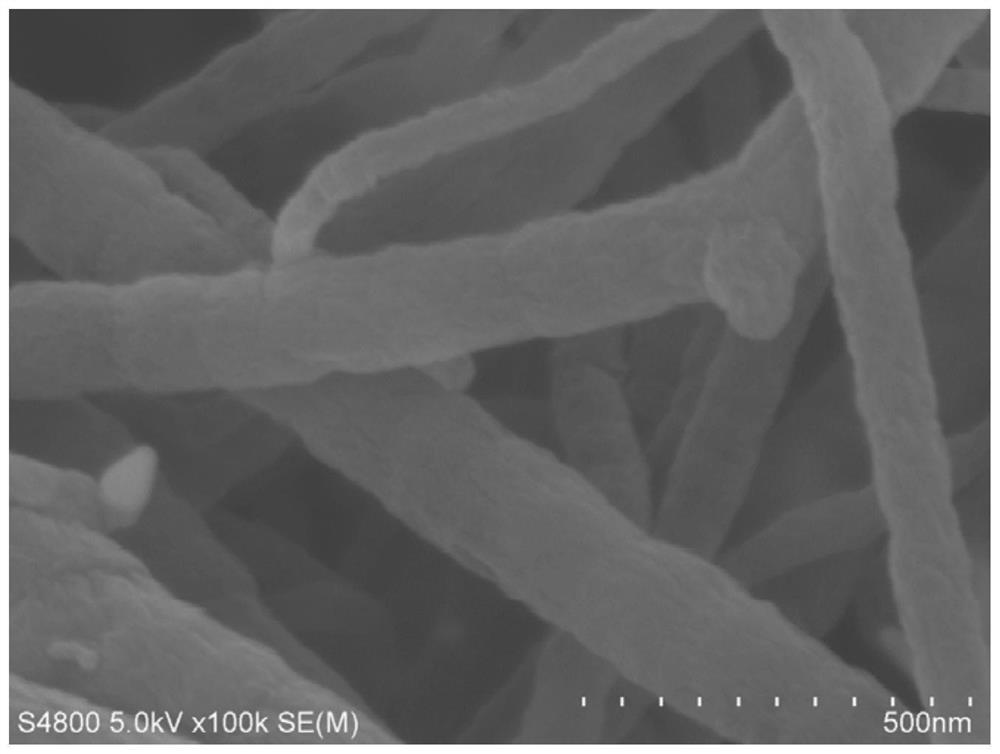

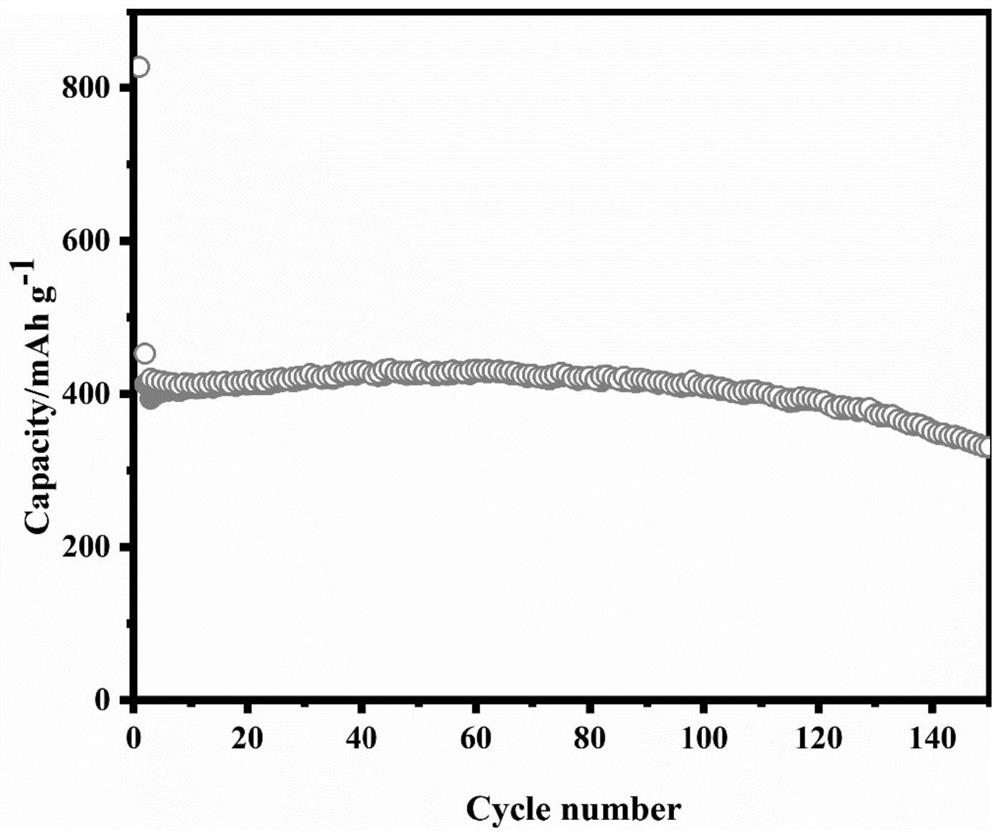

Iron-nickel alloy/carbon nanotube composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, applied in the directions of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of easy occurrence of shuttle effect, inactive chemical properties, etc., and achieve good electron transmission path and mechanical strength. Avoid the shuttle effect, the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix iron ammonium oxalate, nickel nitrate and melamine according to the molar ratio of iron, nickel and carbon atoms at 1:10:50, and grind them in a mortar for 20 minutes to obtain mixture A;

[0029] (2) Put the mixture A into a high-temperature tube furnace, inject 100 sccm of flowing argon gas, first rapidly raise the temperature from room temperature to 200°C at a heating rate of 20°C / min, keep it warm for 0.5h, and then heat it at a rate of 5°C / min The heating rate is slowly raised to 600°C, cooled naturally until the temperature drops to room temperature, and the product B is obtained;

[0030] (3), first fully grind the product B, then seal the ground product B in a glass bottle full of argon through the glove box, then put the glass bottle with the product B into a microwave muffle furnace, and heat it to 200 °C, and after heating, cool to room temperature at a cooling rate of 20 °C / min to obtain an iron-nickel alloy / carbon nanotube composite material.

[0...

Embodiment 2

[0034] (1) Mix ferrous sulfate, nickel sulfate and urea according to the molar ratio of iron, nickel, and carbon atoms in a ratio of 1:5:20, and grind them in a mortar for 20 minutes to obtain mixture A;

[0035] (2) Put the mixture A into a high-temperature tube furnace, inject 100 sccm of flowing argon, first rapidly raise the temperature from room temperature to 200°C at a heating rate of 25°C / min, keep it warm for 0.8h, and then heat it up at a rate of 2°C / min. The heating rate was slowly raised to 650°C, cooled naturally until the temperature dropped to room temperature, and the product B was obtained;

[0036] (3), first fully grind the product B, then seal the ground product B in a glass bottle full of argon through the glove box, then put the glass bottle containing the product B into a microwave muffle furnace, and heat it to 300 °C, and after heating, cool to room temperature at a cooling rate of 20 °C / min to obtain an iron-nickel alloy / carbon nanotube composite mate...

Embodiment 3

[0038] (1) Mix ferrous chloride, nickel chloride and melamine according to the molar ratio of iron, nickel and carbon atoms in a ratio of 1:15:30, and grind in a mortar for 20 minutes to obtain mixture A;

[0039] (2) Put the mixture A into a high-temperature tube furnace, inject 100 sccm of flowing argon gas, first rapidly raise the temperature from room temperature to 150°C at a heating rate of 30°C / min, keep it warm for 1h, and then raise the temperature at a rate of 4°C / min Slowly raise the temperature to 700°C, cool naturally until the temperature drops to room temperature, and take out to obtain product B;

[0040] (3), first fully grind the product B, then seal the ground product B in a glass bottle full of argon through the glove box, then put the glass bottle containing the product B into a microwave muffle furnace, and heat it to 400 °C, and after heating, cool to room temperature at a cooling rate of 20 °C / min to obtain an iron-nickel alloy / carbon nanotube composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com