A single-ion conducting polymer lithium-sulfur battery

A lithium-sulfur battery and polymer technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the safety hazards of metal lithium negative electrodes, restrict the practical application of lithium-sulfur batteries, concentration polarization and other problems, and achieve Improves cycling stability, reduces dissolution and bleed, and avoids the effects of concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of polyacrylonitrile-sulfur: weigh polyacrylonitrile and elemental sulfur in a mass ratio of 1:4, and grind them in a mortar for 1.5 hours to make them evenly mixed. It was then calcined at 350°C for 6 hours under a nitrogen atmosphere with a heating rate of 5°C / min. The product "polyacrylonitrile-sulfur" is obtained after cooling. Elemental analysis shows that the mass fraction of sulfur is about 45wt%.

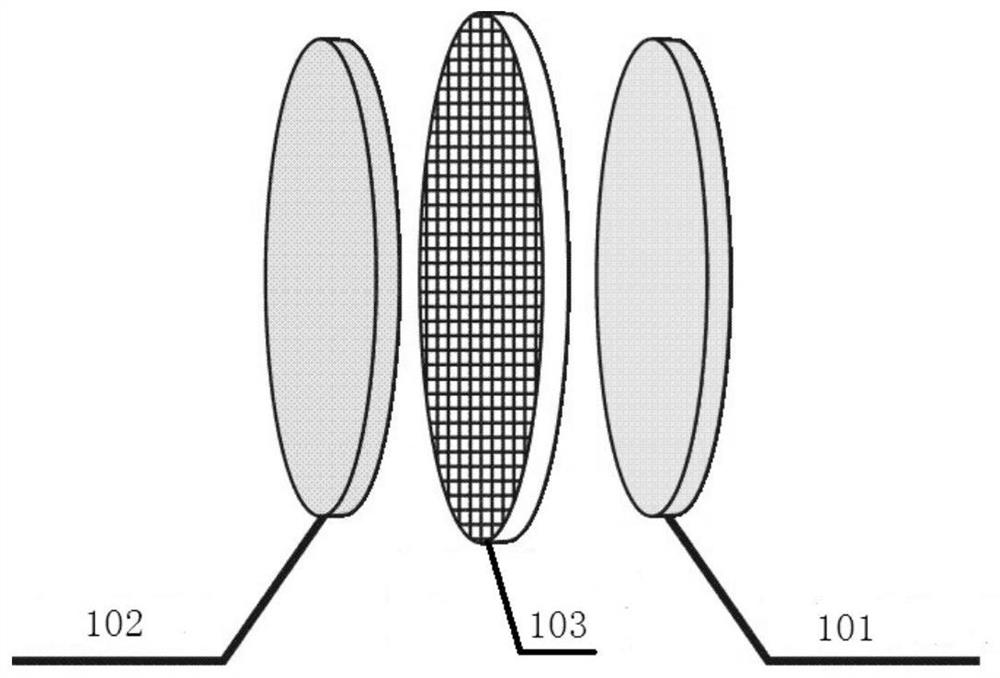

[0036] (2) Preparation of sulfur electrode sheet: Weigh polyacrylonitrile-sulfur, acetylene black and polyvinylidene fluoride sulfur in a small beaker according to the mass ratio of 6:2:2, add an appropriate amount of N-methylpyrrolidone (NMP ), heated and stirred for a period of time to obtain a thick and uniform slurry. The slurry was evenly coated on the surface of the aluminum foil with a scraper, dried at 60°C to remove NMP, then cut into circular positive electrode pieces with a diameter of 16mm with a microtome, and vacuum-dried at 60°C for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com