A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rapid capacity decline, poor conductivity, and low effective sulfur load, and achieve improved cycle stability and efficiency , the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

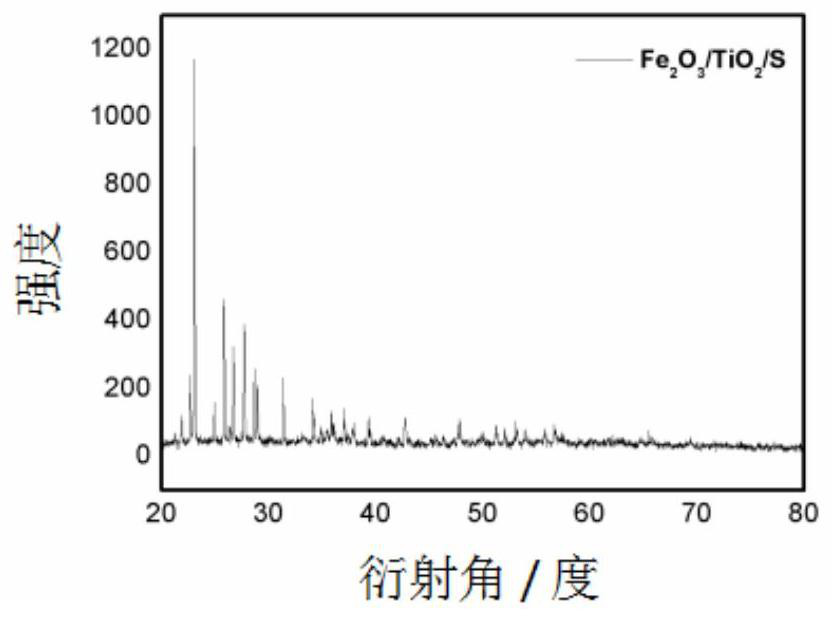

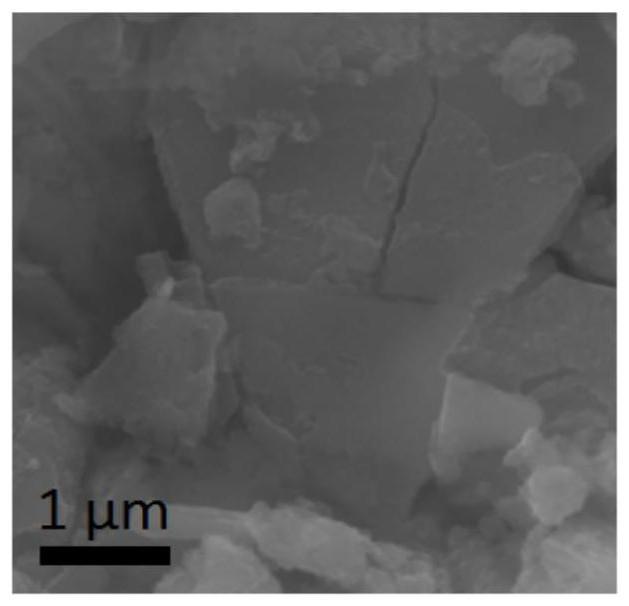

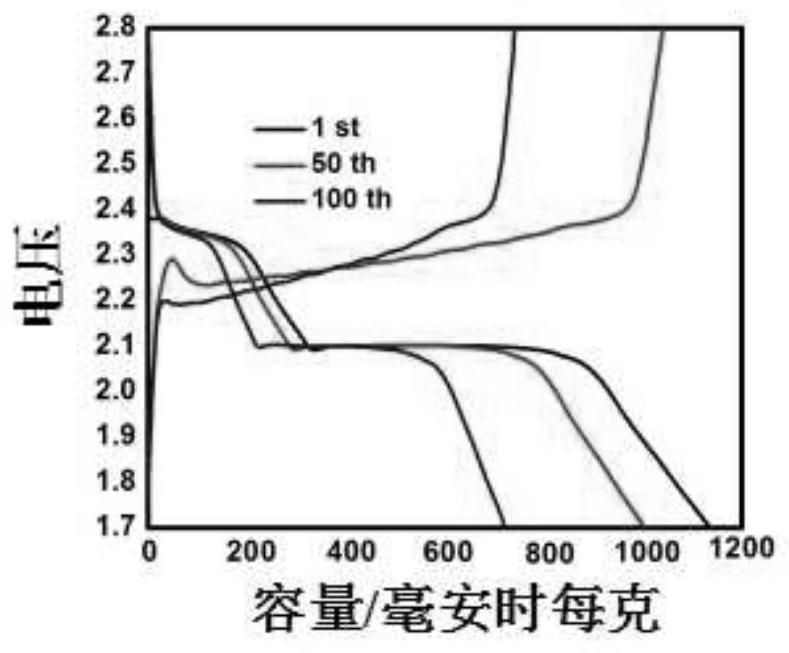

[0033] The positive electrode material of the lithium-sulfur battery, the raw material includes porous Fe 2 o 3 / TiO 2 Composite metal oxide and nano sulfur.

[0034] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0035] (1) Fe 4 Ti 12 Al 94 Alloy strip preparation: Fe was first prepared from Al, Ti and Fe by refining in a vacuum electric arc furnace 4 Ti 12 Al 94 Ingot, in which Al, Ti and Fe are all 99.99wt% high-purity; Fe is then melt-spun 4 Ti 12 Al 94 The ingot is made into an alloy strip with a thickness of 20 μm and a width of 3 mm;

[0036] (2) Porous Fe 2 o 3 / TiO 2 Preparation of composite metal oxides: first divide the alloy ribbon obtained in step (1) into alloy strips each with a mass of 3 g, and then place the alloy strips in 2 L of NaOH solution with a concentration of 2 mol / L and spontaneously oxidize them at 25 ° C for 10 Alloying was carried out by etching Al for 1 hour;...

Embodiment 2

[0042] The positive electrode material of the lithium-sulfur battery, the raw material includes porous Fe 2 o 3 / TiO 2 Composite metal oxide and nano sulfur.

[0043] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0044] (1) Fe 4 Ti 12 Al 94 Alloy strip preparation: Fe was first prepared from Al, Ti and Fe by refining in a vacuum electric arc furnace 4 Ti 12 Al 94 Ingot, in which Al, Ti and Fe are all 99.99wt% high-purity; Fe is then melt-spun 4 Ti 12 Al 94 The ingot is made into an alloy strip with a thickness of 20 μm and a width of 3 mm;

[0045] (2) Porous Fe 2 o 3 / TiO 2 Preparation of composite metal oxides: first divide the alloy ribbon obtained in step (1) into alloy strips each with a mass of 5 g, and then place the alloy strips in 2 L of NaOH solution with a concentration of 2 mol / L and spontaneously oxidize them at 25 °C for 12 Alloying was carried out by etching Al for 1 hour; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com