A method for preparing ktp nonlinear racetrack microring resonators

A microring resonator, racetrack-type technology, applied in nonlinear optics, instruments, optical waveguide light guides, etc., can solve the problems of low optical damage threshold, unsuitable application scenarios, weak resistance to photorefraction, etc., and achieve high optical damage threshold , good operability and repeatability, and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

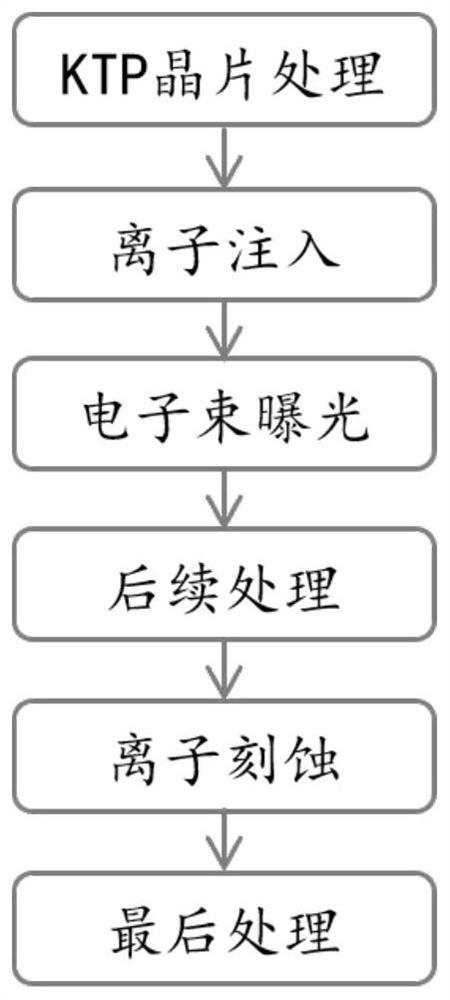

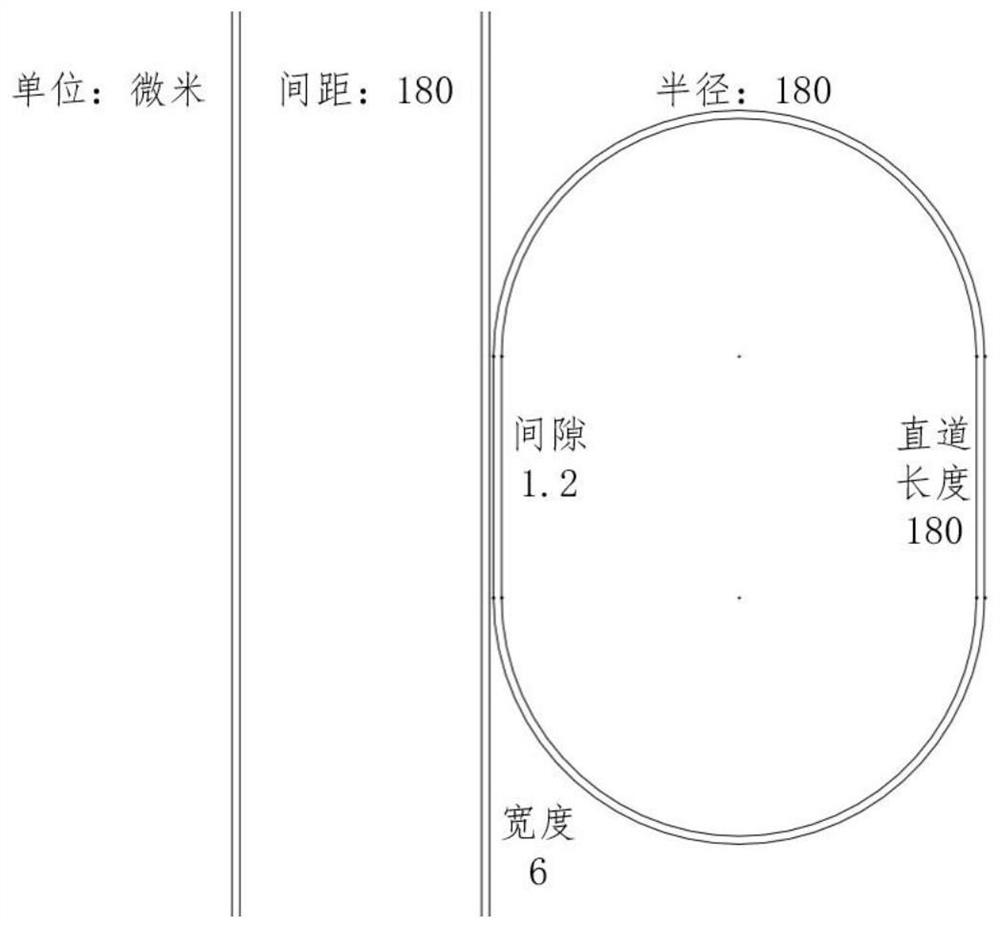

[0044] according to Figure 1-9 As shown, this embodiment proposes a method for preparing a KTP nonlinear racetrack-type microring resonator, including the following steps:

[0045] Step 1. KTP wafer processing

[0046] First, the surface of the cut and formed KTP wafer is polished, and after the polishing is completed, it is cleaned. After cleaning, it is placed in a storage device for storage and standby;

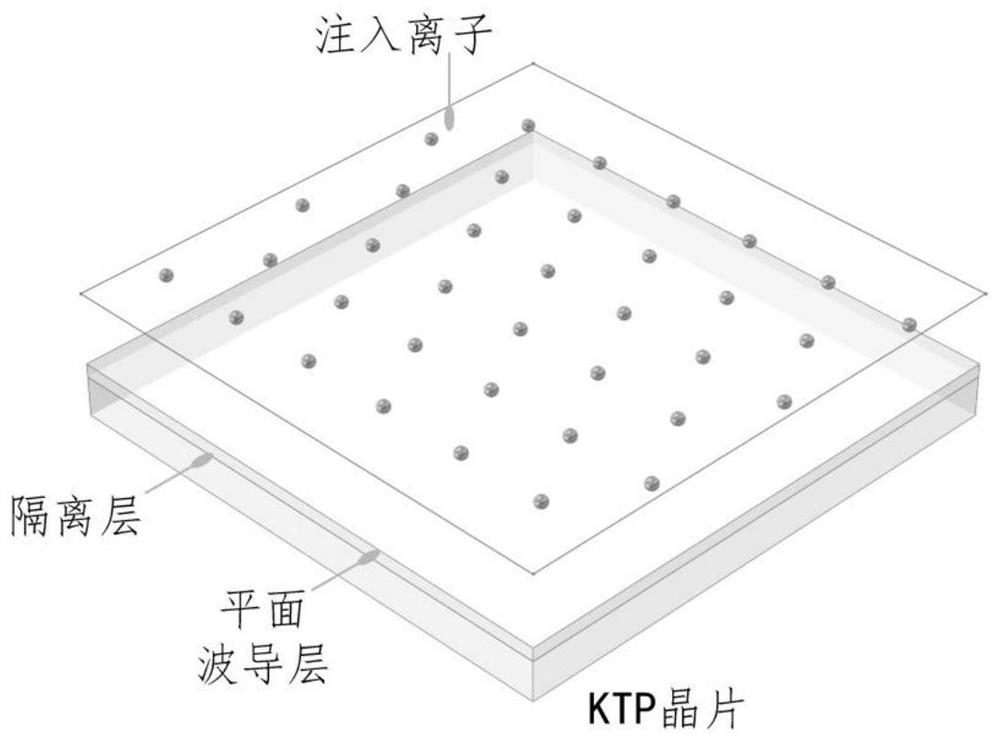

[0047] Step 2. Ion Implantation

[0048] Take out the spare KTP wafer in step 1, and then use ion implantation equipment to implant the ions accelerated by the ion accelerator into the KTP wafer, such as figure 2As shown, an isolation layer with a reduced refractive index is formed at a depth of several microns below the surface of the KTP wafer, and the part above the isolation layer is a waveguide layer. In the second step, the type of ions is one of carbon ions or oxygen ions, In the second step, the range of several micrometers is 5-10 micrometers, and the prepara...

Embodiment 2

[0058] according to Figure 10 As shown, this embodiment takes the generation of frequency doubling (second harmonic) in the band around 1064 nanometers as an example, in which the attached Figure 10 The upper part of the figure is a schematic diagram of the 1064nm frequency doubling of the microring resonator. The arrows indicate the propagation direction of the light. When the KTP crystal undergoes appropriate phase matching processing (cut along a specific angle, such as θ=90°, φ=23.5°, when Class II phase matching can be achieved), which will meet the phase matching conditions of nonlinear frequency doubling.

[0059] At this time, when the 1064-nanometer laser passes through the straight waveguide, it will be coupled to the micro-ring resonator in the form of an evanescent wave (Evanescent Wave). The left and right frequency doubled light, the generated frequency doubled light will also be coupled into the straight waveguide in the form of an evanescent wave, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com