A titanium alloy part with different microstructure distribution and its preparation method

A technology of microstructure and titanium alloy, applied in the field of titanium alloy parts and their preparation, can solve the problems of difficulty in precise control of deformation, difficulty in controlling the distribution of microstructure of parts, and difficulty in forming macroscopic gradient structure, etc., to achieve applicability and flexible, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

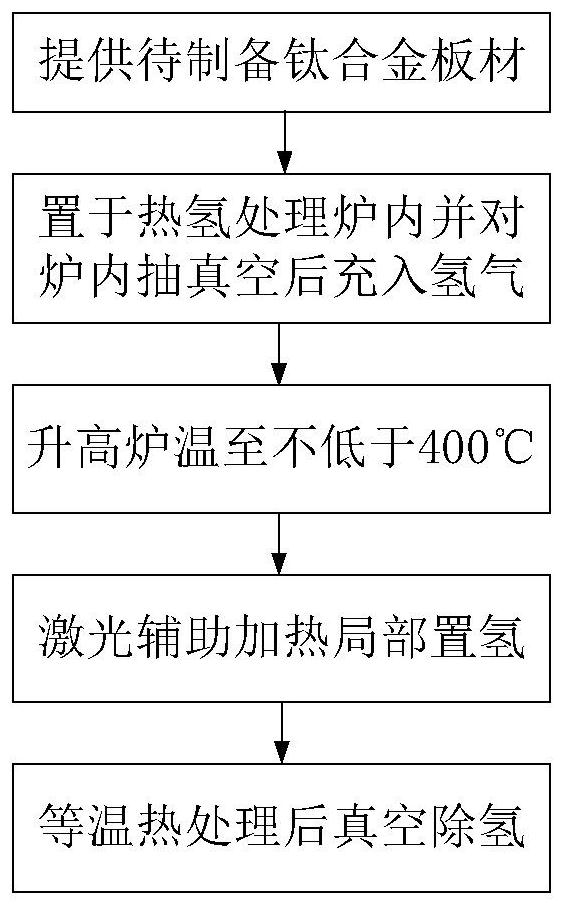

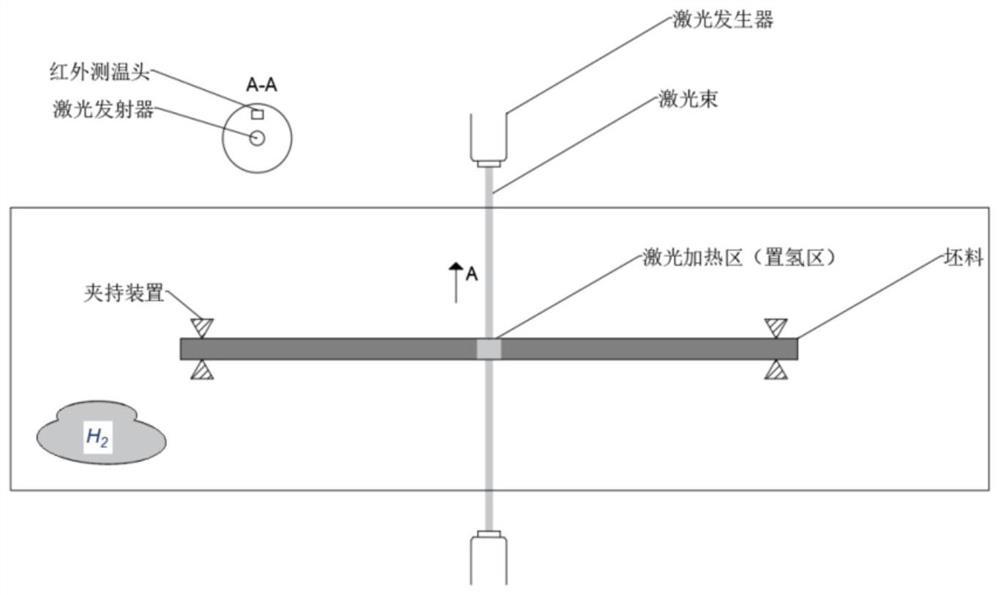

[0026] see figure 1 and figure 2 , the preparation method of titanium alloy parts with different structure distribution provided by the present invention mainly comprises the following steps:

[0027] In step 1, the titanium alloy billet is placed in a hydrogen treatment furnace, and the furnace is evacuated and then filled with a certain amount of hydrogen; then, the furnace temperature is increased to make the hydrogen have a certain diffusivity.

[0028] Specifically, first, put a piece of surface-treated titanium alloy billet into a thermal hydrogen treatment furnace, and vacuumize the furnace, then fill a certain amount of hydrogen into the furnace, and keep it at a certain temperature, Make hydrogen have a certain diffusivity.

[0029] Wherein, the titanium alloy billet is a near-α-type titanium alloy billet or an α+β-type titanium alloy billet; at low temperature, the diffusion of hydrogen in the titanium alloy billet is mainly controlled by diffusion kinetics, and t...

Embodiment 1

[0042] Selecting a Ti65 slab, the method for preparing titanium alloy parts with different microstructure distributions based on laser-assisted heating provided in Example 1 mainly includes the following steps:

[0043] S1, select a 2mm thick Ti65 slab, clean the surface of the Ti65 slab and put it into a hydrogen furnace, then vacuum the furnace and fill it with a certain amount of hydrogen, and raise the furnace temperature to 400°C. Hydrogen has a certain diffusivity and is in a relatively active state.

[0044]S2, turn on the laser to emit a laser beam to heat the middle area of the titanium alloy slab. When the infrared temperature measuring head detects that the temperature of the laser heating zone plate is 750°C, stop increasing the power of the laser beam and keep the current temperature unchanged for 15 minutes. hydrogenation treatment.

[0045] S3, reduce the heating power of the laser beam until zero, move the laser to repeat the operation process of step S2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com