3D cell printing system and printing method thereof

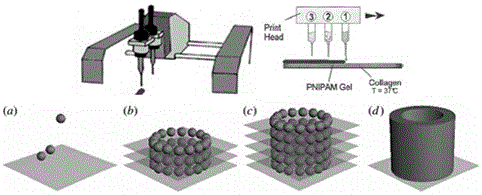

A cell printing and printing system technology, applied in the direction of additive processing, can solve the problems of unfavorable cell contact with each other, organ development and functional expression, limited cell density, slow growth of new tissue, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

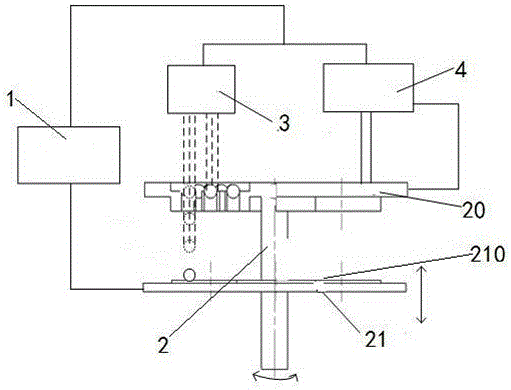

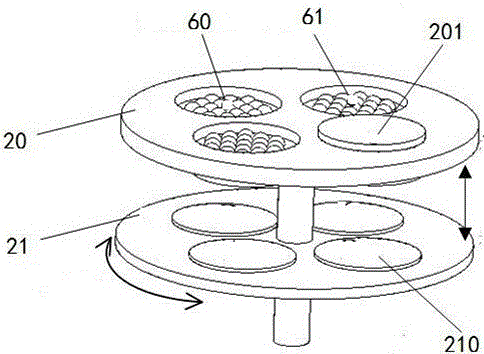

[0042] Such as figure 2As shown, it is a schematic diagram of a 3D cell printing system in a preferred embodiment of the present invention, which includes a general control system 1, a cell printing workbench 2 and a cell control medium system 3, wherein the cell printing workbench 2 is as image 3 As shown, it includes a first workbench 20 and a second workbench 21. The second workbench 21 is located below the first workbench 20. A plurality of cell array installation holes 200 are distributed on the first workbench 20. A cell array of the same type or a different cell array needs to be installed, where the cell array such as Figure 4 As shown, it consists of a plurality of cell hole slots corresponding to the cell shape, and the cell hole slots are through holes, among which Figure 4 a is a schematic diagram of the cell array before capturing cells, Figure 4 b is a schematic diagram of the cell array after the cells are captured. After the cells are captured, they can ...

Embodiment 2

[0049] The printing method of the 3D cell printing system of the present invention specifically includes the following steps:

[0050] S1. Positioning the cell wells in the cell array;

[0051] S2. Obtain the corresponding cell array according to the positioning method of the cell well slot in step S1, and the corresponding cell array is distributed in the cell array installation hole on the first workbench;

[0052] S3. The total control system controls the rotation of the second workbench, so that the forming workbench on the second workbench corresponds to the cell array in step S2;

[0053] S4. The general control system controls the cells to control the medium system to work, so that the cells on the cell array are subjected to the action of the medium, and the cells on the cell array are subjected to a vertical downward force, and the corresponding cells are printed to the corresponding positions of the forming workbench as required. On the surface, the unaffected cells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com