Copper-chromium catalyst as well as preparation method and application thereof

A catalyst, copper-chromium technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of complex process flow and low reaction efficiency, and achieve stable hydrogenation catalytic performance and uniform physicochemical properties. , the effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

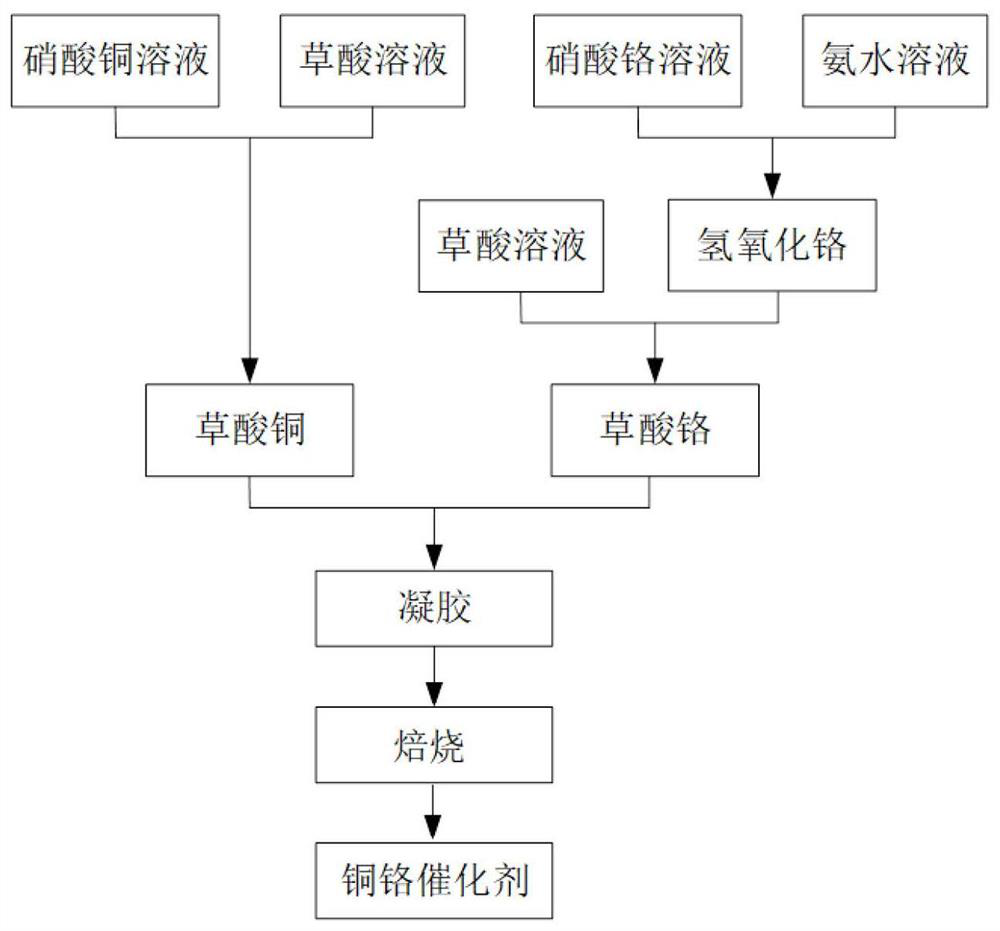

[0079] The present embodiment provides a kind of preparation method of copper chromium catalyst, the process flow diagram of described preparation method is as follows figure 1 shown.

[0080] The preparation method comprises the following steps:

[0081] Measure 263.98mL copper nitrate solution (concentration is 1.0mol / L), then add dropwise 290.38mL oxalic acid solution (concentration is 1.0mol / L, oxalic acid and copper ion molar ratio is 1.1 : 1), aging for 10 hours after the completion of the dropwise addition, and then centrifuging to obtain copper oxalate precipitation for subsequent use.

[0082] Measure 184.22mL of chromium nitrate solution (concentration is 1.0mol / L), then add dropwise 31.32g of ammonia solution (industrial ammonia water with an ammonia mass concentration of 30%) in the chromium nitrate solution at room temperature and under stirring conditions, after the addition is completed, Aging for 10 hours, then filtered to obtain precipitated chromium hydroxi...

Embodiment 2

[0087] The present embodiment provides a kind of preparation method of copper chromium catalyst, and described preparation method comprises the following steps:

[0088] Measure 131.99mL copper nitrate solution (concentration is 2.0mol / L), then add dropwise 263.98mL oxalic acid solution (concentration is 1.0mol / L, oxalic acid and copper ion molar ratio is 1 : 1), aging for 10 hours after the completion of the dropwise addition, and then centrifuging to obtain copper oxalate precipitation for subsequent use.

[0089] Measure 122.81mL of chromium nitrate solution (concentration is 1.5mol / L), then add dropwise 31.32g of aqueous ammonia solution (industrial ammonia water with an ammonia mass concentration of 30%) in the chromium nitrate solution at room temperature and under stirring conditions, after the addition is completed, After aging for 10 hours, filter to obtain chromium hydroxide precipitate for later use.

[0090] The obtained chromium hydroxide precipitate was placed i...

Embodiment 3

[0094] The present embodiment provides a kind of preparation method of copper chromium catalyst, and described preparation method comprises the following steps:

[0095] Measure 175.99mL copper nitrate solution (concentration is 1.5mol / L), then add dropwise 263.98mL oxalic acid solution (concentration is 1.0mol / L, oxalic acid and copper ion molar ratio is 1 : 1), aging for 10 hours after the completion of the dropwise addition, then centrifuging to obtain copper oxalate precipitation for subsequent use.

[0096] Measure 92.11mL of chromium nitrate solution (concentration is 2.0mol / L), then add dropwise 31.32g of ammonia solution (industrial ammonia water with ammonia mass concentration of 30%) in the chromium nitrate solution at room temperature and under agitation. After aging for 10 hours, filter to obtain chromium hydroxide precipitate for later use.

[0097] The obtained chromium hydroxide precipitate was placed in a glass reactor with a stirring and heating jacket with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com