Aqueous zinc ion battery negative electrode, preparation method and battery

A zinc-ion battery, battery negative electrode technology, applied in electrode manufacturing, secondary batteries, active material electrodes, etc., can solve problems such as damage to the overall electrical performance of the battery, increase impedance and polarization, etc., to reduce nucleation overpotential, reduce Polarization and impedance, the effect of increasing the rate of ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

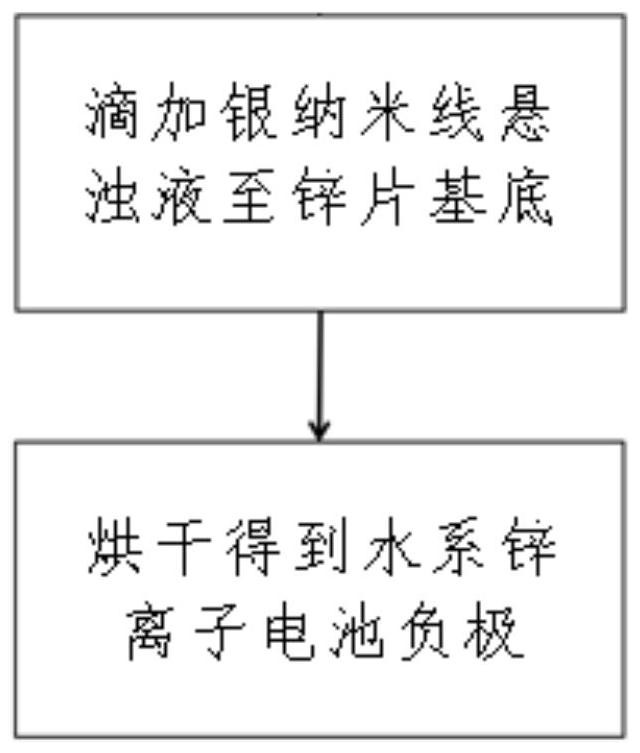

[0030] This embodiment provides a method for preparing an alloy negative electrode of a water-based zinc-ion battery and the alloy negative electrode of a water-based zinc-ion battery prepared by the preparation method. see figure 1 , the method includes:

[0031]First, through the hydrothermal synthesis of silver nanowires, heat 20.75mL of ethylene glycol to 160°C and stir, then completely dissolve 333mg of polyvinylpyrrolidone in 20.75mL of ethylene glycol, and then dissolve 170mg of silver nitrate in 10mL of ethylene glycol In, and mix two kinds of solutions, then take 1.9464g ferric chloride and dissolve in 10mL pure water to prepare 1.2M ferric chloride solution, 1.6134g cupric chloride is dissolved in 10mL pure water and prepare 1.2M ferric chloride solution, and Add 0.75mL each to the mixed solution, and finally react the uniformly mixed solution in a 100mL reactor at 160°C for 6h and repeat the centrifugation four times to prepare a silver nanowire suspension with a c...

Embodiment 2

[0036] This embodiment provides a method for preparing an alloy negative electrode of a water-based zinc-ion battery and the alloy negative electrode of a water-based zinc-ion battery prepared by the preparation method. The methods include:

[0037] First configure the silver nanowire suspension with a concentration of 3.1g / L by the hydrothermal synthesis method of silver nanowires described in Example 1, then add pure water to dilute the concentration of the silver nanowire suspension to 1.9g / L And stir evenly, select the zinc sheet as the negative electrode substrate, drop 1.9g / L uniform silver nanowire suspension at a lower concentration to the zinc sheet, so that the silver nanowire loading on the surface of the zinc sheet is about 0.14mg / cm 2 ; Dry the silver nanowire suspension on the zinc sheet at 60°C for 3 hours to obtain the desired silver nanowire-zinc alloy negative electrode.

[0038] results and analysis:

[0039] The obtained silver nanowire-zinc alloy negativ...

Embodiment 3

[0042] This embodiment provides a method for preparing an alloy negative electrode of a water-based zinc-ion battery and the alloy negative electrode of a water-based zinc-ion battery prepared by the preparation method. The methods include:

[0043] First configure the silver nanowire suspension with a concentration of 3.2g / L by the hydrothermal synthesis method of silver nanowires described in Example 1, then add pure water to dilute the concentration of the silver nanowire suspension to 2g / L and Stir evenly, select the zinc sheet as the negative electrode substrate, add 2g / L uniform silver nanowire suspension with a lower concentration to the zinc sheet, so that the silver nanowire loading on the surface of the zinc sheet is about 0.15mg / cm 2 ; Dry the silver nanowire suspension on the zinc sheet at 60°C for 3 hours to obtain the desired silver nanowire-zinc alloy negative electrode.

[0044] results and analysis:

[0045] The obtained silver nanowire-zinc alloy negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com