Vapor-phase synthesis of porous zn current collectors for lithium metal anodes with controllable thickness

A lithium metal negative electrode, gas-phase synthesis technology, applied in metal material coating process, electrode carrier/current collector, vacuum evaporation plating, etc. High yield, uniform deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

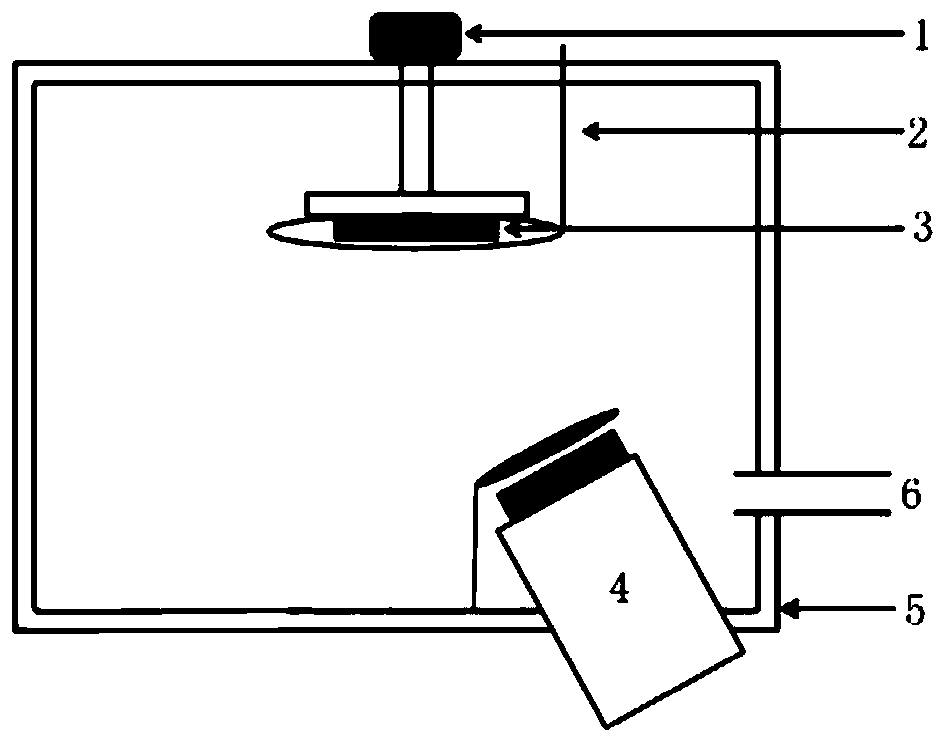

[0040] Embodiment 1: have the vapor phase synthesis method of different thickness Zn film, its synthetic steps are as follows:

[0041] (a) Before sputtering, increase the distance between the target and the substrate and maintain a certain inclination;

[0042] (b) Install the Zn target and connect it to the RF power supply; fix the cleaned quartz glass substrate on the substrate in the high vacuum chamber; start vacuuming to make the background vacuum of each chamber reach 2×10 -4 Pa;

[0043] (c) Adjust the flow meter and the molecular pump to allow Ar gas to flow into the chamber, adjust the pressure of Ar gas to 0.8Pa, turn on the power supply and adjust the power to 40W, start pre-sputtering, and the pre-sputtering time is 1h;

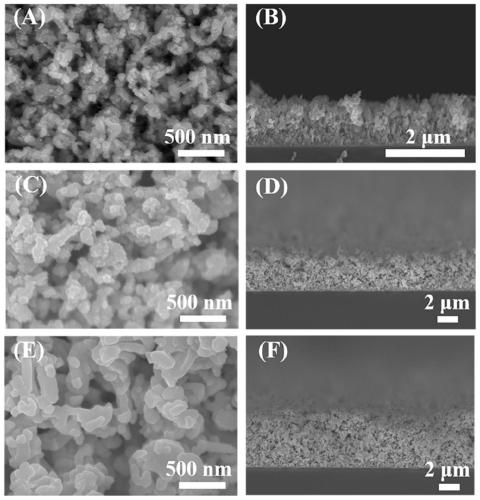

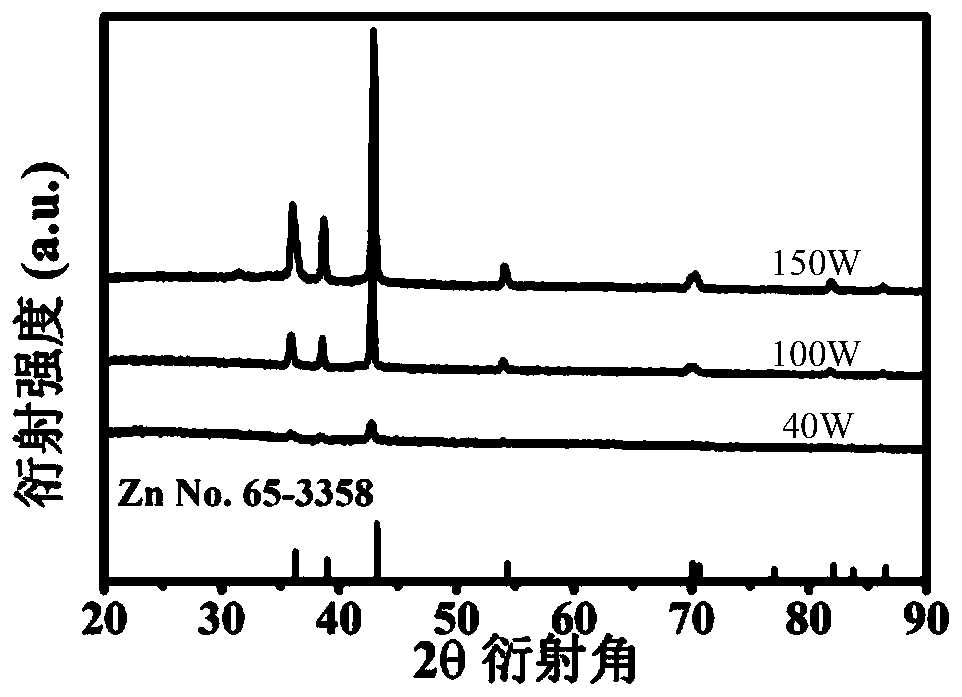

[0044] (d) The deposition rate of the porous film can be measured by SEM. Deposit the porous film directly on the silicon wafer to test the size and shape of the nanoparticles, and deposit the porous film directly on the copper wafer as the lit...

Embodiment 2

[0046] Embodiment 2: have the vapor phase synthesis method of different thickness Zn film, its synthetic steps are as follows:

[0047] (a) Before sputtering, increase the distance between the target and the substrate and maintain a certain inclination;

[0048] (b) Install the Zn target and connect it to the RF power supply; fix the cleaned quartz glass substrate on the substrate in the high vacuum chamber; start vacuuming to make the background vacuum of each chamber reach 2×10 -4 Pa;

[0049] (c) Adjust the flow meter and the molecular pump to allow Ar gas to flow into the chamber, adjust the pressure of Ar gas to 0.8Pa, turn on the power supply and adjust the power to 100W, start pre-sputtering, and the pre-sputtering time is 1h;

[0050] (d) The deposition rate of the porous film can be measured by scanning electron microscopy. The porous film is directly deposited on a silicon wafer to test the size and shape of the nanoparticles. Battery test its coulombic efficiency;...

Embodiment 3

[0052] Embodiment 3: have the vapor phase synthesis method of different thickness Zn film, its synthetic steps are as follows:

[0053] (a) Before sputtering, increase the distance between the target and the substrate and maintain a certain inclination;

[0054] (b) Install the Zn target and connect it to the RF power supply; fix the cleaned quartz glass substrate on the substrate in the high vacuum chamber; start vacuuming to make the background vacuum of each chamber reach 2×10 -4 Pa;

[0055] (c) Adjust the flow meter and the molecular pump to allow Ar gas to flow into the chamber, adjust the pressure of Ar gas to 0.8Pa, turn on the power supply and adjust the power to 150W, start pre-sputtering, and the pre-sputtering time is 1h;

[0056] (d) The deposition rate of the porous film can be measured by scanning electron microscopy. The porous film is directly deposited on a silicon wafer to test the size and shape of the nanoparticles. Battery test its coulombic efficiency;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com