Potassium metal battery negative electrode, preparation method and application thereof, and potassium metal battery

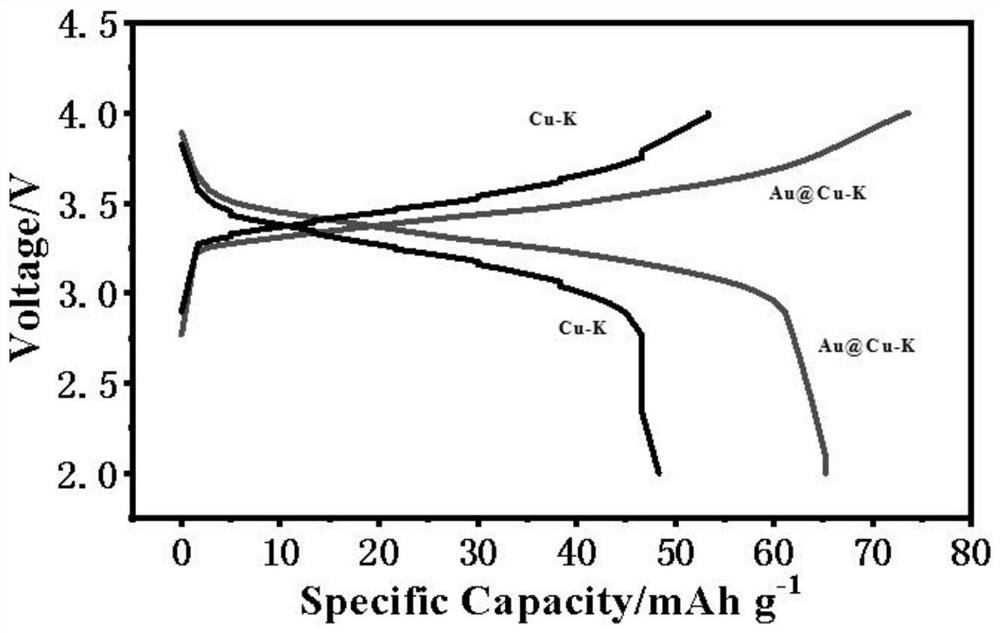

A metal battery, negative electrode technology, applied in battery electrodes, electrode carriers/current collectors, negative electrodes, etc., can solve the problems of poor copper affinity, unsatisfactory electrochemical performance, large nucleation overpotential, etc., and achieve uniform deposition. , The effect of inhibiting the growth of dendrites and high coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Such as Figure 6 As shown, the present invention also provides a method for preparing the negative electrode of the potassium metal battery described in the above technical scheme, comprising the following steps:

[0032] Immersing foamed copper in a chloroauric acid solution to obtain a gold-loaded foamed copper current collector;

[0033] Pressing the gold-loaded copper foam current collector and the potassium sheet to obtain the negative electrode of the potassium metal battery;

[0034] The gold-loaded copper foam current collector and potassium flakes were of the same size.

[0035] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0036] In the invention, the copper foam is impregnated in a chloroauric acid solution to obtain a gold-loaded copper foam current collector.

[0037] In the present invention, the concentration of the chloroauric acid solution...

Embodiment 1

[0072] Mix 200mg of chloroauric acid trihydrate with 60mL deionized, and stir evenly to obtain a chloroauric acid solution;

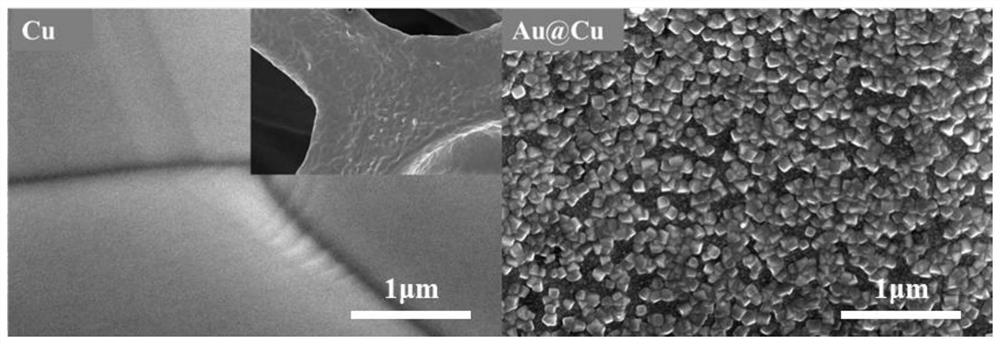

[0073] Foam copper (thickness is 1mm) is placed in the hydrochloric acid solution of 1mol / L 5min, removes the oxide on the surface, then washes with deionized water and absolute ethanol successively, dries, obtains the pretreated foam copper;

[0074] After immersing 15g of pretreated foamed copper in 60mL of the chloroauric acid solution under static conditions for 1min, wash with deionized water, and vacuum-dry at 80°C for 9h to obtain a gold-loaded copper foam current collector ;

[0075] Under an argon atmosphere, the gold-loaded copper foam current collector and the potassium sheet (0.4 mm in thickness) were cut into a circle with a diameter of 12 mm, then stacked and laminated, and pressed using a tablet press. The combined pressure is 150psi, and the holding time is 30s, so that the potassium sheet is completely embedded in the pores of the gold...

Embodiment 2

[0084] Mix 200mg of chloroauric acid trihydrate with 60mL deionized, and stir evenly to obtain a chloroauric acid solution;

[0085] Foam copper (thickness is 1mm) is placed in the hydrochloric acid solution of 1mol / L 5min, removes the oxide on the surface, then washes with deionized water and absolute ethanol successively, dries, obtains the pretreated foam copper;

[0086] After immersing 10 g of pretreated foamed copper in 60 mL of the chloroauric acid solution under static conditions for 1.5 min, wash it with deionized water, and dry it in vacuum at 80 ° C for 11 h to obtain a gold-loaded foamed copper aggregate. fluid;

[0087] Under an argon atmosphere, the gold-loaded copper foam current collector and the potassium sheet (thickness 0.4mm) were cut into a circle with a diameter of 12mm, and then stacked and laminated using a tablet press. The combined pressure is 150psi, and the holding time is 30s, so that the potassium sheet is completely embedded in the pores of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com