Preparation method of silicon-based negative electrode material based on polyamic acid-based electrode binder

A silicon-based negative electrode material and polyamic acid-based technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of limited ability to inhibit expansion, cycle stability, complex composition and ratio requirements, etc., to achieve The effect of improving cycle stability, enhancing structural integrity and volume stability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this Example 1, a polyamic acid copolymer modified by a silane coupling agent as a binder, a method of preparing a silicon-based negative electrode material based on a polyamic acid-based electrode adhesive, and specifically, the steps are as follows: nanometers Silicon powder, silane coupling modified polyamic acid copolymers and SUPER P are weighed by weight ratio of 90: 5: 5, and N-methyl-2-pyrrolidone is added, and the mixture is stirred at room temperature for 30 min to form uniform slurry. The slurry was applied to a copper foil having a thickness of 5 μm, transferred to a vacuum drying tank, and dried at 70 ° C for 12 h. The resulting current collector is punched into a sheet, and the density of the active material is 1 mg / cm. 3 Electrode of lithium battery.

Embodiment 2

[0021] In this Example 2, a polyamic acid copolymer modified by a silane coupling agent is used as an adhesive, a method of preparing a silicon-based negative electrode material based on a polyamic acid-based electrode adhesive, and specifically includes the steps: nanometers Silicon powder, silane coupling modified polyamic acid copolymer and SUPER P are weighed according to weight ratio of 80:10:10, and N-methyl-2-pyrrolidone is added, and the mixture is stirred at room temperature for 30 min to form uniform slurry. The slurry was applied to a copper foil having a thickness of 5 μm, transferred to a vacuum drying tank, and dried at 70 ° C for 12 h. The resulting current collector is punched into a sheet, and the density of the active material is 1 mg / cm. 3 Electrode of lithium battery.

Embodiment 3

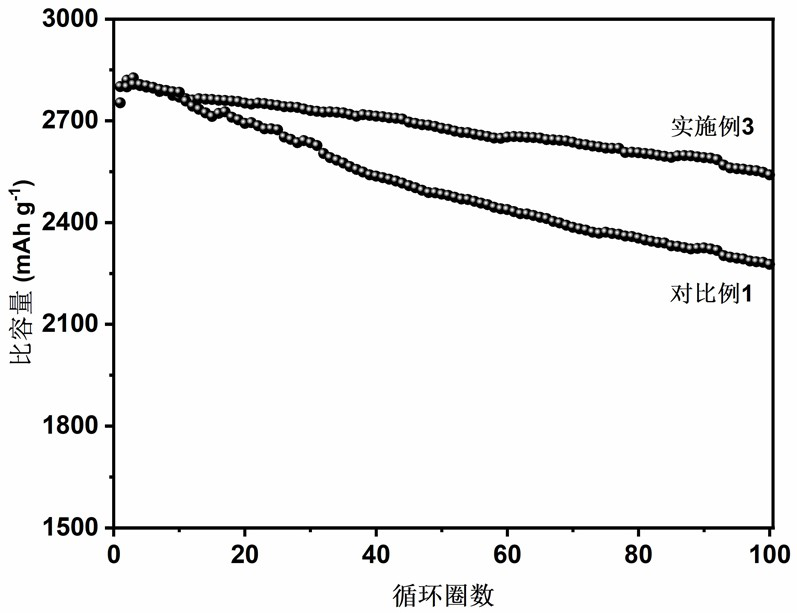

[0023] In this Example 3, a polyamic acid copolymer modified by a silane coupling agent as a binder, a method of preparing a silicon-based negative electrode material based on a polyamic acid-based electrode adhesive, and specifically, the steps are as follows: nanometers Silicon powder, silane coupling modified polyamic acid copolymer and SUPER P are weighed according to weight ratio of 70:15:15, and N-methyl-2-pyrrolidone is added, and stirred at room temperature for 30 min to form uniform slurry. The slurry was applied to a copper foil having a thickness of 5 μm, transferred to a vacuum drying tank, and dried at 70 ° C for 12 h. The resulting current collector is punched into a sheet, and the density of the active material is 1 mg / cm. 3 Electrode of lithium battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com