Wear-resistant and corrosion-resistant injection molding composite material and manufacturing method of pump accessory

A composite material and injection molding technology, which is applied in the field of polymer composite materials and pump parts manufacturing, can solve problems such as insufficient surface hardness, insufficient material strength, and low shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, raw materials are:

[0031] High-density polyethylene, 43 parts by mass, with a crystallinity of 70% and a melt index of 17g / 10min; purchased from high-density polyethylene produced by ExxonMobil.

[0032] Linear low-density polyethylene, 25 parts by mass, a crystallinity of 62%, and a melt index of 40g / 10min; purchased from linear low-density polyethylene produced by ExxonMobil.

[0033] Ultra-high molecular weight polyethylene, 25 parts by mass, with a molecular weight of 8 to 12 million; purchased from ultra-high molecular weight polyethylene produced by Ticona Corporation of the United States.

[0034] Reinforcing fiber, 10 parts by mass; basalt fiber, produced by Zhejiang Shijin Basalt Fiber Co., Ltd. The fiber surface activation process uses 1.0wt% surface modifier of the fiber. The surface modifier uses KH-550 silane coupling agent. The surface activation and drying are processed in the laboratory according to the existing conventional techno...

Embodiment 2

[0039] In this embodiment, raw materials are:

[0040] High-density polyethylene, 50 parts by mass, with a crystallinity of 85%, and a melt index of 20g / 10min; purchased from linear low-density polyethylene produced by ExxonMobil.

[0041] Linear low-density polyethylene, 30 parts by mass, crystallinity is 70%, and melt index is 50g / 10min; purchased from the linear low-density polyethylene produced by ExxonMobil.

[0042] Ultra-high molecular weight polyethylene, 15 parts by mass, with a molecular weight of 8 to 12 million; purchased from ultra-high molecular weight polyethylene produced by Ticona Corporation of the United States.

[0043] Reinforcing fiber, 5 parts by mass; sepiolite fiber, produced by Hebei Hongli sepiolite cashmere Co., Ltd. The fiber surface activation process uses 1.5wt% surface modifier of the fiber, the surface modifier uses a mixture of KH-550 silane coupling agent and American Kenrich KR-12 titanate coupling agent in a mass ratio of 1:1, Surface act...

Embodiment 3

[0048] In this embodiment, raw materials are:

[0049] High-density polyethylene, 35 parts by mass, with a crystallinity of 70%, and a melt index of 15g / 10min; purchased from high-density polyethylene produced by ExxonMobil.

[0050] Linear low-density polyethylene, 20 parts by mass, crystallinity is 55%, and melt index is 30g / 10min; purchased from the linear low-density polyethylene produced by ExxonMobil.

[0051] Ultra-high molecular weight polyethylene, 35 parts by mass, with a molecular weight of 8 to 12 million; purchased from ultra-high molecular weight polyethylene produced by Ticona Corporation of the United States.

[0052] Reinforcing fiber, 15 parts by mass; potassium hexatitanate whisker, produced by Shanghai Whisker Composite Material Co., Ltd. The fiber surface activation process uses 0.5wt% surface modifier of the fiber, the surface modifier uses KR-12 titanate coupling agent from Kenrich Company of the United States, and the surface activation and drying are ...

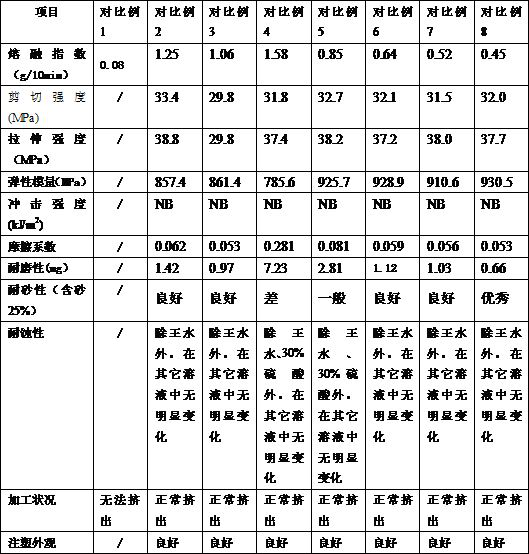

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com