Tremella-like MoS2/functionalized activated carbon sodium-ion battery negative electrode material and preparation method thereof

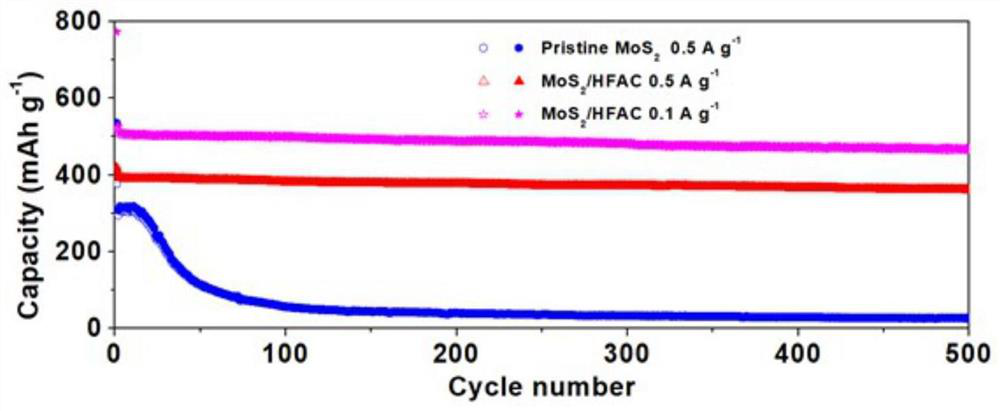

A technology of sodium ion battery and negative electrode material, applied in the direction of active material electrode, battery electrode, negative electrode, etc., can solve the problems of poor electronic conductivity of electrode material, loss of active sites, poor conductivity, etc., to achieve low cost and improve stability , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

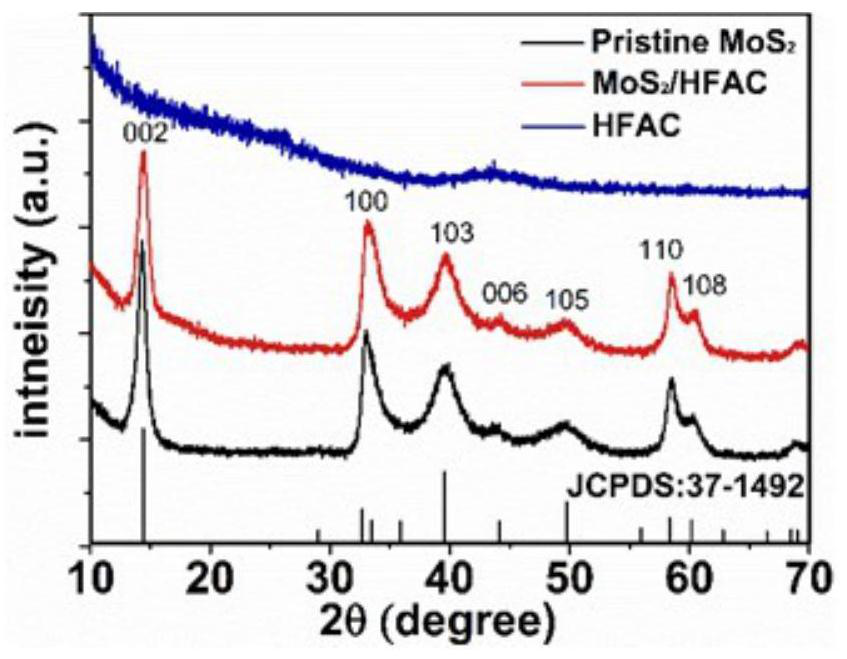

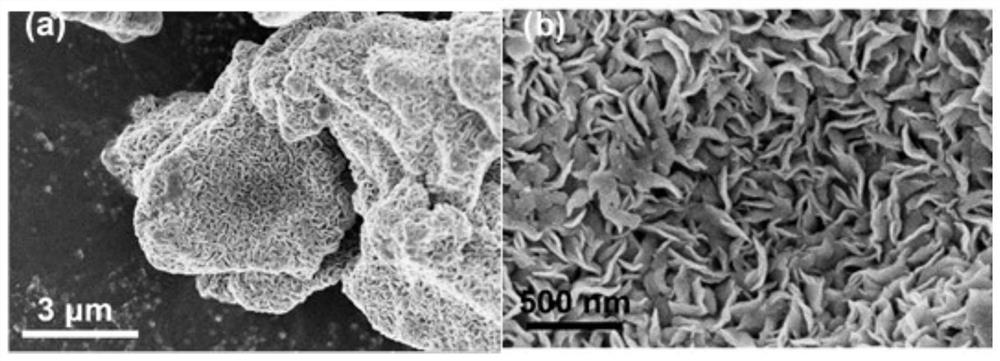

[0024] The invention provides a tremella-like MoS 2 The preparation method of functionalized activated carbon sodium ion battery negative electrode material specifically comprises the following steps:

[0025] Step 1: Mix 0.1~1.0g AC and 0.5~2.0g NaNO 3 Disperse in 10-100mL concentrated sulfuric acid, then magnetically stir at 30-100°C for 1-5h to obtain a dispersion; add 0.5-4.0g KMnO 4 After grinding, gradually add to the dispersion liquid, then dilute the above mixture with 50~200mL deionized water, and let it stand for 12~36h; then centrifuge the diluted mixture, wash it several times with deionized water and absolute ethanol, and freeze-dry 8-24 hours to obtain HFAC;

[0026] Step 2: Disperse 0.01-0.50g HFAC in 10-50mL of ethanol and ultrasonically for 10-60 minutes, record it as dispersion A; 2 MoO 4 and 0.1~1.5g C 2 h 5 Dissolve all NS in 5-20mL deionized water until a clear solution B is formed;

[0027] Step 3: Add solution A to dispersion B, stir magnetically ...

Embodiment 1

[0031] Include the following steps:

[0032] (1) Mix 1.0g AC and 2.0g NaNO 3 Disperse in 100mL of concentrated sulfuric acid, then magnetically stir at 100°C for 5h to obtain a dispersion, and 2.0g of KMnO 4 After grinding, gradually add to the dispersion liquid, then dilute the above mixture with 200 mL deionized water, and let it stand for 36 h; centrifuge the diluted mixture, wash with deionized water and ethanol several times, and obtain HFAC by freeze-drying for 24 h;

[0033] (2) Disperse 0.50g HFAC in 50mL ethanol and sonicate for 60 minutes, which is recorded as solution A; by continuous stirring, 1.0g Na 2 MoO 4 and 1.5g C 2 h 5 NS was completely dissolved in 20mL deionized water until a clear solution B was formed;

[0034] (3) Add solution A to solution B, stir it magnetically for 10 hours, then transfer the resulting liquid to a high-pressure reactor, heat it to 200 degrees Celsius at a heating rate of 10 degrees Celsius / min, keep it warm for 20 hours, and aft...

Embodiment 2

[0036] Include the following steps:

[0037] (1) Mix 0.4g AC and 1.0g NaNO 3 Disperse in 50mL of concentrated sulfuric acid, and then magnetically stir at 80°C for 1h to obtain a dispersion. Add 2.0g of KMnO 4 After grinding, gradually add to the dispersion liquid, then dilute the above mixture with 100mL deionized water, and let stand for 36h; centrifuge the diluted mixture, wash with deionized water and ethanol several times, and obtain HFAC by freeze-drying for 20h;

[0038] (2) Disperse 0.03g HFAC in 20mL ethanol and sonicate for 30 minutes, which is recorded as solution A; by continuous stirring, 0.24g Na 2 MoO 4 and 0.45g C 2 h 5 NS was completely dissolved in 10 mL deionized water until a clear solution B was formed;

[0039] (3) Add solution A to solution B, stir it magnetically for 1 hour, then transfer the resulting liquid to a high-pressure reactor, heat it to 200 degrees Celsius at a heating rate of 5 degrees Celsius / min, keep it warm for 20 hours, and after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com