High-heat-resistance single-component adhesive and preparation method thereof

A one-component, adhesive technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of cracking and sealing, poor long-term reliability, large residual stress, etc., to achieve high resistance Improved low temperature impact performance, unaffected bond strength, and improved toughness of cured products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of a high heat-resistant one-component adhesive, the steps are as follows:

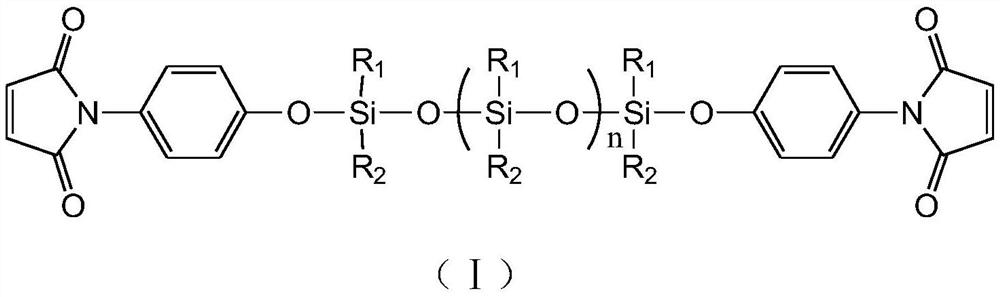

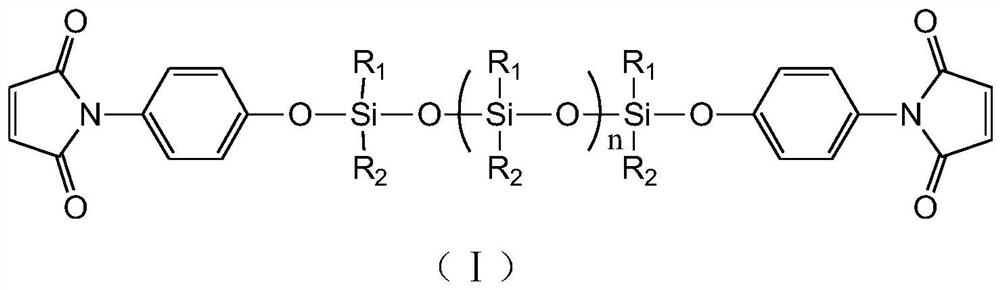

[0050] The first part of the preparation of bismaleimide resin

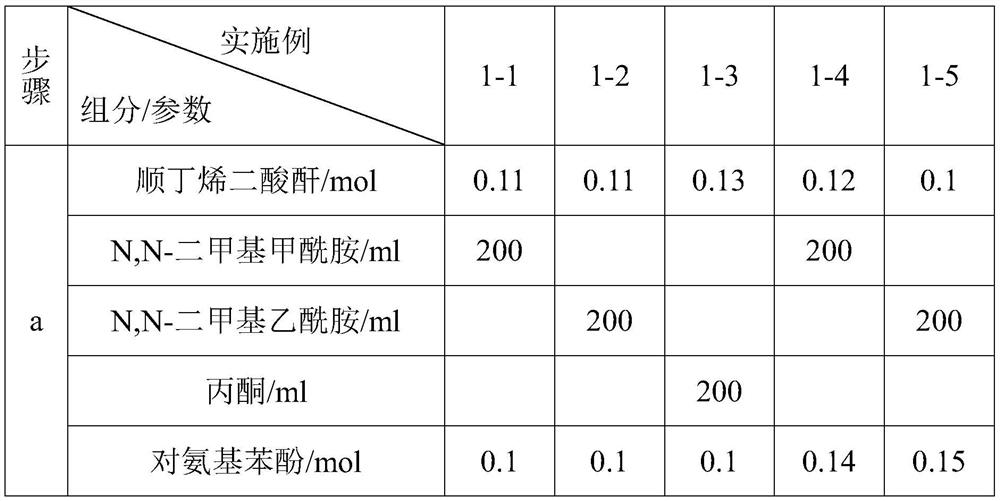

Embodiment 1-1~1-5

[0051] Embodiment 1-1~1-5: Preparation of bismaleimide resin

[0052] Implementation steps:

[0053] (a) Add 0.1-0.15mol maleic anhydride and 200ml solvent into a round-bottomed flask equipped with a stirrer, thermometer and reflux condenser, stir to dissolve, then slowly add 0.1-0.15mol p-aminophenol, and react at room temperature 2 to 3 hours, then add 0.0001mol to 0.001mol of catalyst, heat up and reflux for 3 to 4 hours, then cool, water analysis, suction filtration, and recrystallization to obtain N-(4-hydroxyphenyl)maleimide;

[0054] (b) Add 0.1mol N-(4-hydroxyphenyl)maleimide and 100mL solvent to a round bottom flask A equipped with a stirrer, a thermometer and a reflux condenser, and stir to dissolve; in another vessel B Add 0.05mol chlorine-terminated polysiloxane, 50mL solvent, and 0.05-0.2mol alkaline substance to make a mixed solution C; slowly drop the mixed solution C into the round bottom through a constant pressure dropping funnel at 0-10°C In flask A, react...

Embodiment 2-1~2-7

[0063] Examples 2-1 to 2-7: Preparation of toughened modified bismaleimide resin

[0064] Implementation steps:

[0065] Add 0.1mol of bismaleimide resin into a three-necked flask, heat it to 100-140°C to melt it, then add 0.01-0.1mol of allyl compound, and stir at a constant temperature of 100-140°C for 10-60min to make it fully Prepolymerize, discharge and cool, grind into powder, and filter with a 2000-mesh sieve to obtain a resin powder with a particle size D50 within 20 μm.

[0066] The allyl compound is selected from 2,2'-diallyl bisphenol A or 2-allylphenol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com