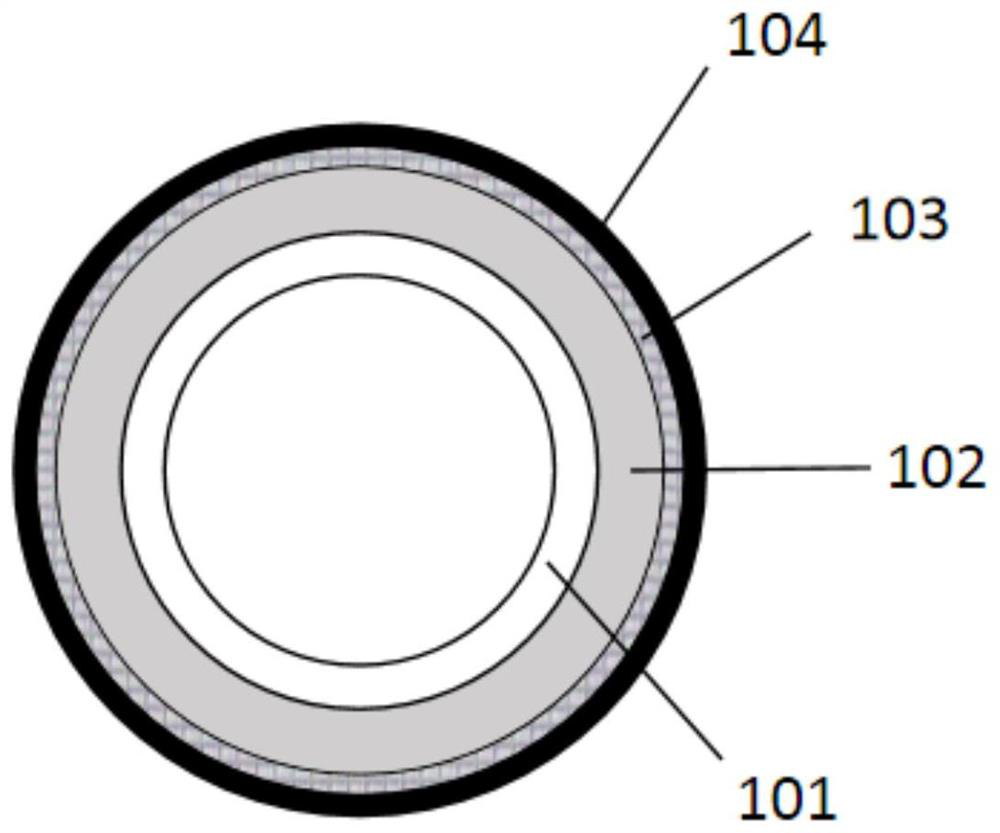

ESEPI prefabricated heat-preservation directly-buried heat-resistant high-density polyethylene low-temperature heat supply composite pipe

A high-density polyethylene and composite pipe technology, applied in the direction of thermal insulation, protection of pipes and pipes through thermal insulation, etc. problem, to achieve good thermal insulation effect, small molding shrinkage, good crack resistance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of white material in the components of rigid polyurethane foam:

[0063] Including ingredients:

[0064] Polyoxypropylene glycol 30 parts, aliphatic polyester polyol 10 parts, monofluorodichloroethane 10 parts, polysiloxane 2 parts, dibutyltin dilaurate 0.5 parts, triethyl phosphate 5 parts, expandable 10 parts of graphite;

[0065] Preparation:

[0066] Mix aliphatic polyester polyol, polyoxypropylene glycol, and expandable graphite evenly, then add monofluorodichloroethane, polysiloxane, triethyl phosphate, and dibutyltin dilaurate, and mix evenly to obtain polyol Composition, i.e. white material;

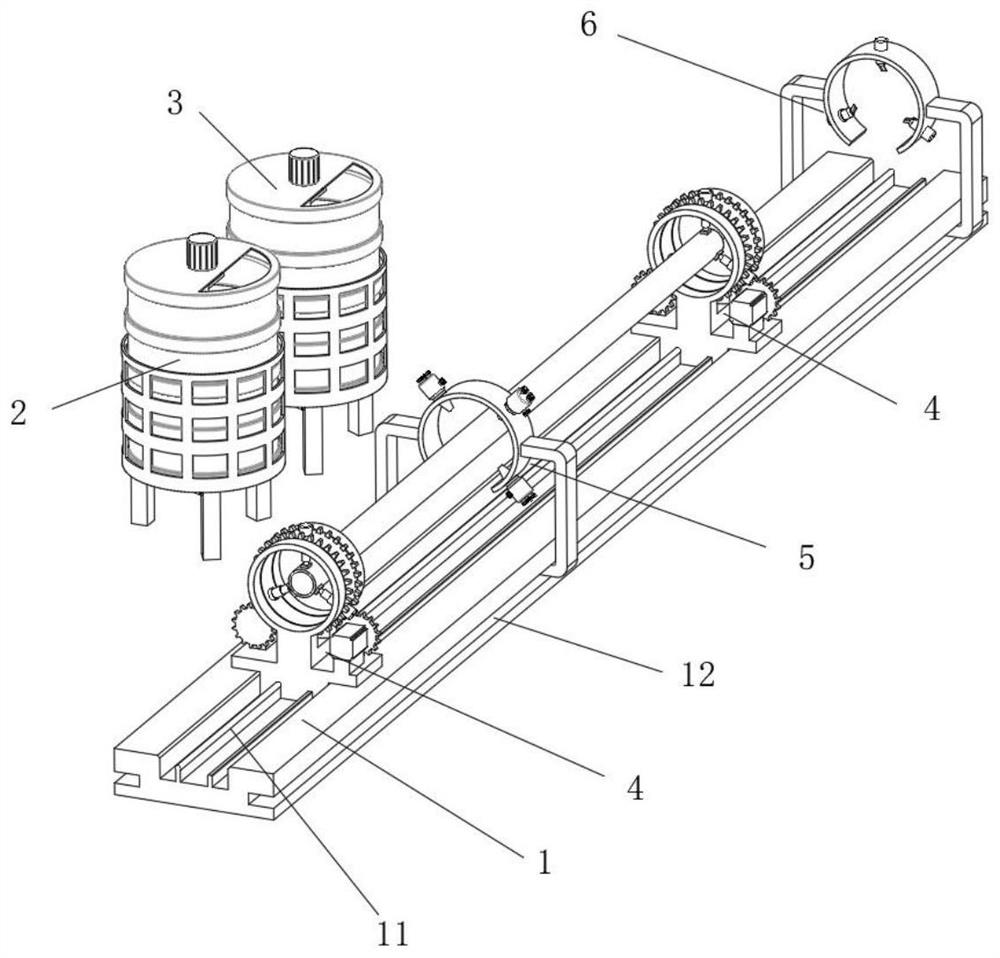

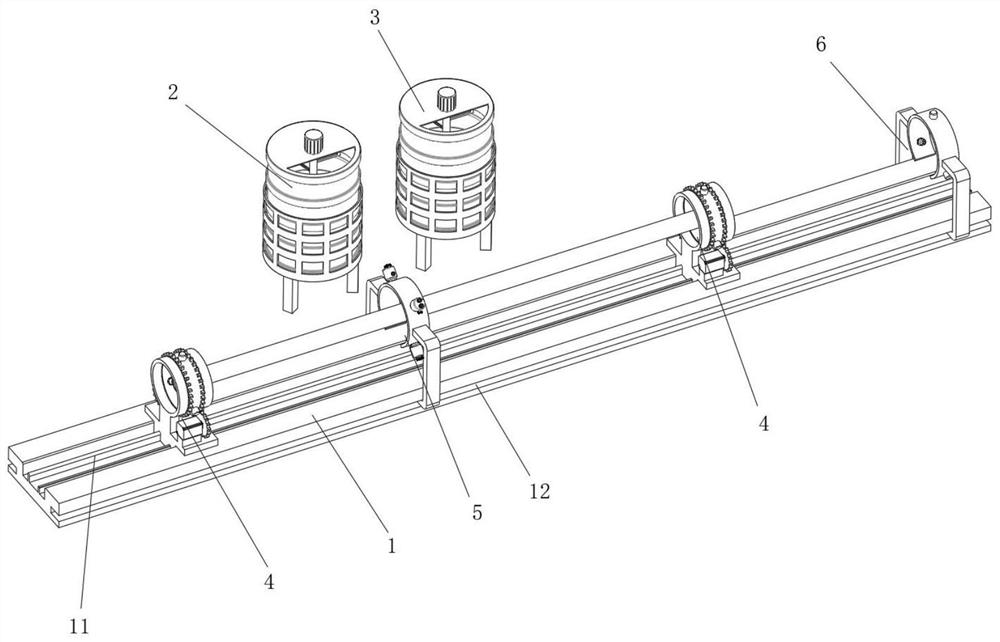

[0067] Preparation of high-density polyethylene pipes for coiled high-toughness sprinkler irrigation:

[0068] (1) Perform surface decontamination and cleaning pretreatment on the outer wall of PE-RT II heat-resistant polyethylene pipe;

[0069] (2) Prepare an insulation layer on the outer wall of the pretreated working tube:

[0070] 1) Fixed working tub...

Embodiment 2

[0077] Preparation of white material in the components of rigid polyurethane foam:

[0078] Including ingredients:

[0079] 50 parts of polytetrahydrofuran ether glycol, 30 parts of aromatic polyester polyol, 30 parts of fluorodichloroethane, 4 parts of polysiloxane, 1.5 parts of triethylenediamine, tris(dipropylene glycol) phosphite 15 parts, 25 parts of expandable graphite;

[0080] Preparation:

[0081] Mix aromatic polyester polyol, polytetrahydrofuran ether glycol, and expandable graphite evenly, then add fluorodichloroethane, polysiloxane, tris(dipropylene glycol) phosphite and triethylenediamine, Mix evenly to obtain polyol composition, ie white material.

[0082] The preparation process of the coiled high-toughness high-density polyethylene pipe for sprinkler irrigation is the same as in Example 1.

Embodiment 3

[0084] Including ingredients:

[0085] 20 parts of polyoxypropylene diol, 20 parts of polytetrahydrofuran ether diol, 10 parts of aliphatic polyester polyol, 10 parts of aromatic polyester polyol, 20 parts of fluorodichloroethane, 3 parts of polysiloxane , 1 part of triethanolamine, 5 parts of triethyl phosphate, 5 parts of tris(dipropylene glycol) phosphite, 15 parts of expandable graphite;

[0086] Preparation:

[0087] Mix aliphatic polyester polyol, aromatic polyester polyol, polyoxypropylene glycol polytetrahydrofuran ether glycol and expandable graphite evenly, then add fluorodichloroethane, polysiloxane, triethyl phosphate Ester, tris(dipropylene glycol) phosphite and triethanolamine are uniformly mixed to obtain a polyol composition, that is, a white material.

[0088] The preparation process of the coiled high-toughness high-density polyethylene pipe for sprinkler irrigation is the same as in Example 1.

[0089] In Examples 1-3, the selected black material is PM200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com