Material for realizing relaxation-normal ferroelectric phase change through doping, and method thereof

A ferroelectric phase and normal technology, which is applied to materials and fields that realize relaxor-normal ferroelectric phase transition through doping, can solve complex chemical compositions, difficult relaxor-normal ferroelectric phase transition, disturbed long-range ferroelectric phase transition order and other problems, to achieve the effect of no complex process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

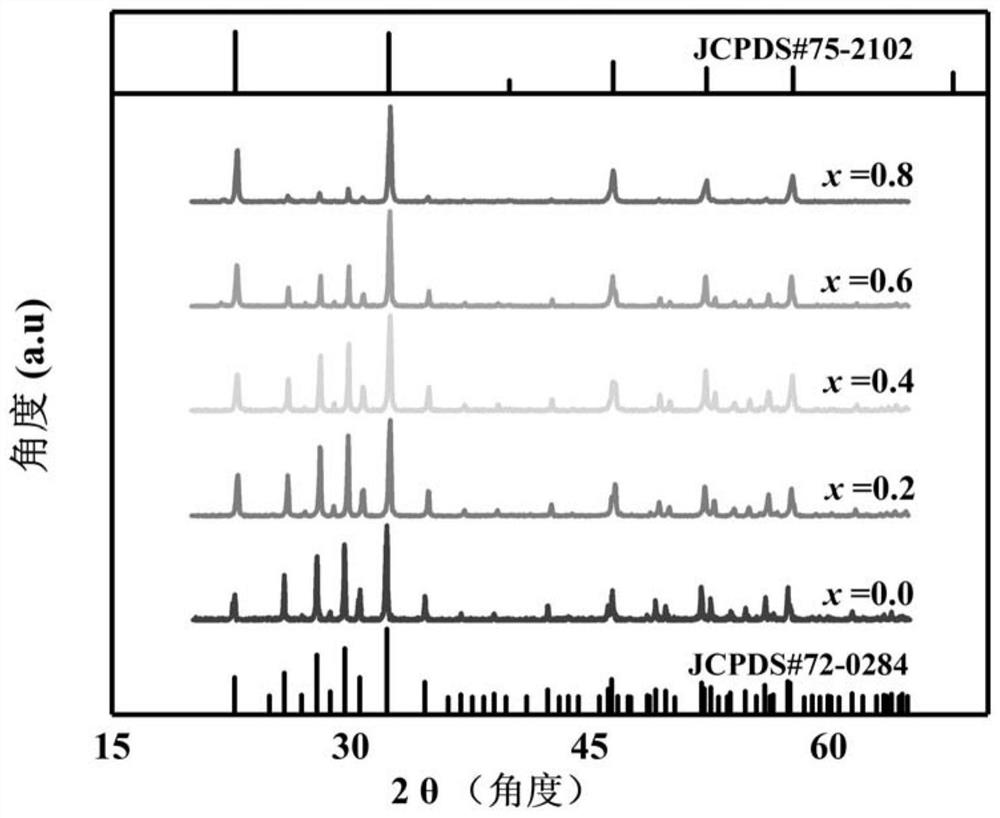

[0020] Weighing 3.9144 grams SrCO 3 Powder, BaCO 1.7441 g 3 Powder and 9.3501 g Nb 2 O 5 Powder (x = 0), with an appropriate amount into a ball mill jar, and milling beads were added approximately 2 / 3 of ball mill pot volume of distilled water, ball milled for 24 hours to mix well. The resulting dried powder was treated with the appropriate amount of pressure 15MPa powder is pressed into a diameter of about 20 mm, the bulk thickness of about 5-6 mm. In Al 2 O 3 Crucible lid bottom with a thin layer of powder is mixed, and then molded into a good block, of Al 2 O 3 Cover discs on the crucible, causing the block to a sealed state. The crucible was placed in a muffle furnace, heat from room temperature to 400 ℃ 30 minutes and then heated to the sintering temperature (1400 deg.] C) for 3 hours after the temperature was lowered to 400 ℃, followed by furnace cooling to room temperature, ramp rate control in the entire 5 ℃ / min. After the obtained ceramic block, which is hand ground wit...

Embodiment 2

[0022] Weigh 3.2076 g SBN single phase powder, 0.1115 g Na 2 CO 3 Powder and 0.2805 g Nb 2 O 5Powder (x = 0.2), into a ball mill jar milled with an appropriate amount of beads was added and about 2 / 3 of the tank volume ethanol milling, ball milled for 24 hours to mix well. The resulting slurry is dried, the amount of pressure 15MPa powder was pressed into a diameter of about 10 mm, a sheet thickness of about 2-3 mm. In Al 2 O 3 Laying a thin layer of the bottom of the crucible component powder, and then molded into a sheet good, and the cover sheet with the powder, and finally Al 2 O 3 Wafer on the crucible cover, the sheet in a sealed state. The sheet is sealed crucible placed in a muffle furnace and heated, heat from room temperature to 400 ℃ 30 minutes and then heated to the sintering temperature (1250 deg.] C) for 3 hours after the temperature was lowered to 400 ℃, followed by furnace cooling to room temperature, the whole ramp rate control at 5 ℃ / min. Obtaining the formula ...

Embodiment 3

[0024] Single phase weighed 2.4057 g and 0.2230 g Na powder SBN 2 CO 3 Powder and 0.5610 g Nb 2 O 5 Powder (x = 0.4), into a ball mill jar milled with an appropriate amount of beads was added and about 2 / 3 of the tank volume ethanol milling, ball milled for 24 hours to mix well. The resulting slurry is dried, the amount of pressure 15MPa powder was pressed into a diameter of about 10 mm, a sheet thickness of about 2-3 mm. In Al 2 O 3 Spread a thin layer of the crucible bottom and then molded into a sheet after the good component powder, and the powder was covered with a sheet, finally Al 2 O 3 Wafer on the crucible cover, the sheet in a sealed state. The sheet is sealed crucible placed in a muffle furnace and heated, heat from room temperature to 400 ℃ 30 minutes and then heated to the sintering temperature (1200 deg.] C) for 3 hours after the temperature was lowered to 400 ℃, followed by furnace cooling to room temperature, the whole ramp rate control at 5 ℃ / min. Obtaining the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com