Self-breeding rod and preparation method thereof as well as preparation method of hypoeutectic aluminum-silicon alloy semi-solid slurry

A technology of semi-solid slurry and aluminum-silicon alloy, which is applied in the preparation of hypoeutectic aluminum-silicon alloy semi-solid slurry, self-inoculation rod and its preparation field, and can solve the problem that self-inoculant cannot ensure uniform dispersion and block self-inoculation Solve the problems of complex preparation of reagents and long time-consuming electromagnetic stirring, and achieve the effect of short preparation cycle, small structure and round shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a self-inoculating rod, comprising the steps of:

[0045] (1) Conduct energy spectrometer composition identification on the purchased aluminum-silicon alloy base material to determine the alloy composition;

[0046] (2) Perform differential thermal analysis on the purchased aluminum-silicon alloy base material to determine the temperature range of the solid-liquidus line of the alloy;

[0047] (3) Using a resistance furnace to heat the A356 aluminum-silicon alloy base material with a silicon content of 5% to 8% at 750°C, and after it is completely melted, pour it into a copper mold for rapid cooling;

[0048] (4) Cut the rapidly cooled metal plate into long strips with a cross section of 10mm×10mm and a length of 200mm by wire cutting; remove the surface oxide skin through sandpaper polishing, and put it in a drying oven for standby.

[0049] The present invention also provides a self-inoculating rod, which is prepared by u...

Embodiment 1

[0061]Use a resistance furnace to melt the A356 alloy base material with a silicon content of 5% to 8%. After stirring, degassing, refining, slag removal, and standing, move it to a crucible on an electromagnetic stirrer with a preheating temperature of 640°C. . When the temperature of the molten metal is stabilized at 640°C, turn off the heating function of the electromagnetic stirrer, turn on the electromagnetic stirrer with a stirring frequency of 30 Hz and a stirring power of 90%, and then insert a self-incubating glass with an initial temperature of 20°C (room temperature) into the crucible. When the temperature of the molten metal drops to 610°C, pull out the self-inoculation rod; then keep electromagnetic stirring, when the temperature of the molten metal drops to 600°C, stop the electromagnetic stirring, take a sample with a sampling spoon, put it into brine for rapid cooling, and prepare gold Phase sample observation.

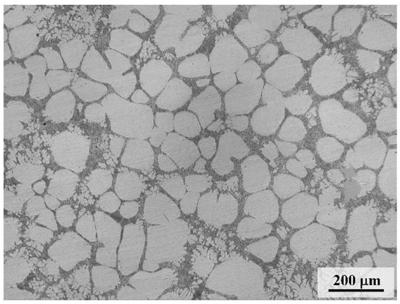

[0062] Such as figure 1 As shown, in the quenc...

Embodiment 2

[0064] Use a resistance furnace to melt the A356 alloy base material with a silicon content of 5% to 8%. After stirring, degassing, refining, slag removal, and standing, move it to a crucible on an electromagnetic stirrer with a preheating temperature of 640°C. . When the temperature of the molten metal is stabilized at 640°C, turn off the heating function of the electromagnetic stirrer, turn on the electromagnetic stirrer with a stirring frequency of 30 Hz and a stirring power of 90%, and then insert a self-incubating glass with an initial temperature of 20°C (room temperature) into the crucible. When the temperature of the molten metal drops to 605°C, pull out the self-inoculation rod; then keep electromagnetic stirring, when the temperature of the molten metal drops to 600°C, stop the electromagnetic stirring, take a sample with a sampling spoon, put it into brine for rapid cooling, and prepare gold Phase sample observation.

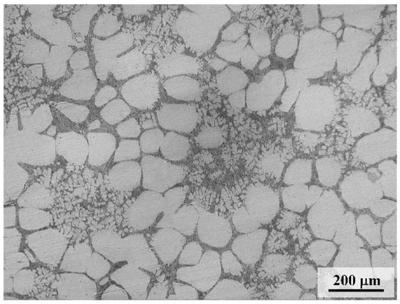

[0065] Such as figure 2 As shown, in the que...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com