Primer-topcoat waterborne coating and preparation method thereof

A water-based coating and bottom surface technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex coating process and poor corrosion resistance, and achieve enhanced internal structure, good adhesion and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

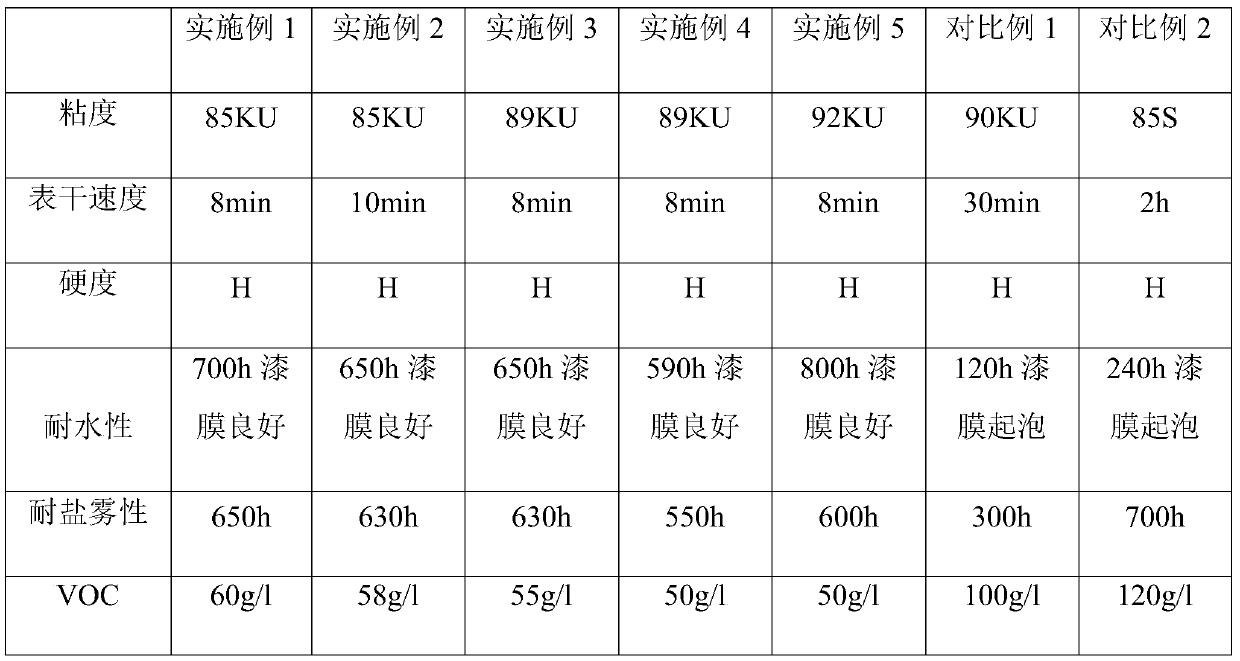

Embodiment 1

[0045] An embodiment of the present invention provides a bottom-surface-in-one water-based coating, which includes the following raw material components in mass percentage: 35% epoxy ester resin, 14% epoxy-modified acrylic resin, 0.3% defoamer, and 0.3% dimethylethanolamine , dispersant 2.5%, aluminum trimer metaphosphate 5%, zinc silicate 3%, zinc aluminum phosphate 3%, superfine barium sulfate 6%, titanium dioxide 15%, substrate wetting agent 0.6%, thickener 2 %, anti-settling agent 1%, anti-flash rust agent 0.4%, ultraviolet absorber 1%, dipropylene glycol butyl ether 2%, drier 0.6% and deionized water 8.3%.

[0046] The epoxy ester resin is the water-based epoxy ester resin produced by Changzhou Guangshu Chemical Technology Co., Ltd.; the epoxy-modified acrylic resin is the water-based epoxy-modified acrylic emulsion produced by Wuxi Diai Epoxy Co., Ltd.; The defoamer is a mixture of 941PL pioneered by France and BYK-028 by BYK, wherein the mass ratio of 941PL and BYK-028 ...

Embodiment 2

[0052] An embodiment of the present invention provides a water-based coating with a bottom surface, which includes the following raw material components in mass percentage: 30% epoxy ester resin, 11% epoxy-modified acrylic resin, 0.3% defoamer, and 0.2% dimethylethanolamine , dispersant 3%, aluminum trimer metaphosphate 6%, zinc silicate 4%, zinc aluminum phosphate 2%, calcium silicate 6%, carbon black 16%, superfine barium sulfate 6%, substrate wetting agent 1 %, thickener 1%, anti-settling agent 0.5%, anti-flash rust agent 0.2%, ultraviolet absorber 2%, dipropylene glycol butyl ether 3.4%, drier 0.4% and deionized water 7%.

[0053] The grades of the above-mentioned components are the same as in Example 1, except that the defoamer is a mixture of 941PL pioneered by France and BYK-028 of BYK, wherein the mass ratio of 941PL and BYK-028 is 1:0.8 The dispersant is AFCONA4560; the substrate wetting agent is a mixture of TEGO-100 of Tego and BYK-331 of BYK, wherein the mass ratio...

Embodiment 3

[0059] An embodiment of the present invention provides a water-based coating with a bottom surface, which includes the following raw material components in mass percentage: 32% epoxy ester resin, 17% epoxy-modified acrylic resin, 0.3% defoamer, and 0.2% dimethylethanolamine , dispersant 2.8%, aluminum trimer metaphosphate 4%, zinc silicate 2%, zinc aluminum phosphate 4%, superfine barium sulfate 4%, carbon black 16%, substrate wetting agent 0.6%, thickener 1 %, anti-settling agent 0.5%, anti-flash rust agent 0.3%, ultraviolet absorber 1.5%, dipropylene glycol butyl ether 5%, drier 0.3% and deionized water 8.5%.

[0060] The grades of the above-mentioned components are the same as in Example 1, except that the defoamer is a mixture of 941PL pioneered by France and BYK-028 of BYK, wherein the mass ratio of 941PL and BYK-028 is 1:0.9 The dispersant is AFCONA4560; the substrate wetting agent is a mixture of TEGO-100 of Tego and BYK-331 of BYK, wherein the mass ratio of TEGO-100 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com