Supercritical carbon dioxide after-finishing process of wave-absorbing electromagnetic shielding fabric

A carbon dioxide, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, electrical components, fiber types, etc., can solve the problems of easy generation of eddy current, easy corrosion, limited physical elasticity, etc., and achieve the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

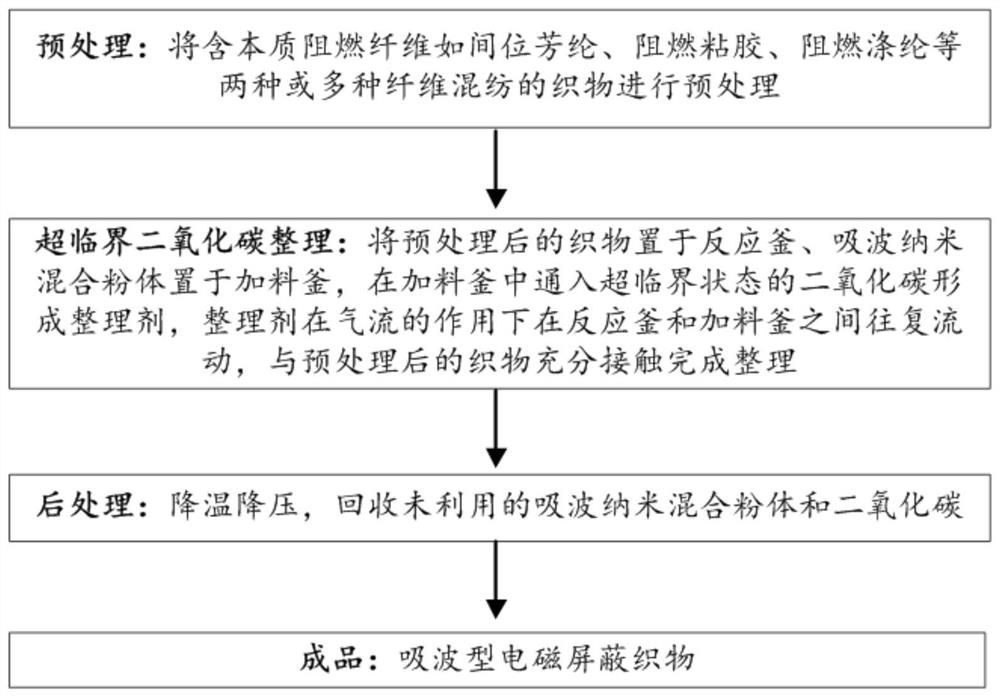

Method used

Image

Examples

Embodiment 1

[0039] (1) Fabric pretreatment. The meta-aramid fabric was pretreated with acetone. The treatment temperature is 60°C, the treatment time is 40min, and the drying temperature is 80°C.

[0040] (2) Finishing with supercritical carbon dioxide. take m 1 Gram is placed in high temperature and high pressure reactor through the fabric after step (1) treatment, simultaneously quality is 0.25m 1 gram of composite wave-absorbing nanopowder and 0.05m 1 Grams of the entrainer mixture were placed in the addition kettle. Among them, the composite absorbing powder is composed of graphene, carbon nanotubes, ferrite and MXene-Ti 3 C 2 , the mass ratio of the four is 4:3:2:1. The carbon dioxide in the critical state after heating and pressurizing is passed into the feeding kettle at a flow rate of 20g / min, and it is mixed and dissolved with the composite wave-absorbing nano-powder and the entrainer to form a finishing agent. Under the action of the circulation device, the formed The fi...

Embodiment 2

[0042] Fabric pretreatment. The blended fabric of meta-aramid and flame retardant viscose was pretreated with ethanol. The treatment temperature is 40°C, the treatment time is 60min, and the drying temperature is 60°C.

[0043] Supercritical carbon dioxide finishing. take m 2 The fabric treated by step (1) is placed in a high-temperature and high-pressure reactor, and the quality is 0.15m 2 gram of composite wave-absorbing nanopowder and 0.03m 2 Grams of the entrainer mixture were placed in the addition kettle. Among them, the composite absorbing powder is composed of graphene, carbon nanotubes, ferrite and MXene-Ti 3 C 2 , the mass ratio of the four is 4:3:2:1. The carbon dioxide in the critical state after heating and pressurizing is passed into the feeding kettle at a flow rate of 30g / min, and it is mixed and dissolved with the composite wave-absorbing nano-powder and the entraining agent to form a finishing agent. Under the action of the circulation device, the form...

Embodiment 3

[0045] Fabric pretreatment. The flame-retardant polyester and flame-retardant viscose blended fabric was pretreated with ethanol. The treatment temperature is 50°C, the treatment time is 50min, and the drying temperature is 60°C.

[0046] Supercritical carbon dioxide finishing. take m 3 The fabric treated by step (1) is placed in a high-temperature and high-pressure reactor, and the quality is 0.1m 3 gram of composite wave-absorbing nanopowder and 0.03m 3 Grams of the entrainer mixture were placed in the addition kettle. Among them, the composite absorbing powder is composed of graphene, carbon nanotubes, ferrite and MXene-Ti 3 C 2 , the mass ratio of the four is 4:3:2:1. The carbon dioxide in the critical state after heating and pressurizing is passed into the feeding kettle at a flow rate of 30g / min, and it is mixed and dissolved with the composite wave-absorbing nano-powder and the entraining agent to form a finishing agent. Under the action of the circulation device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com