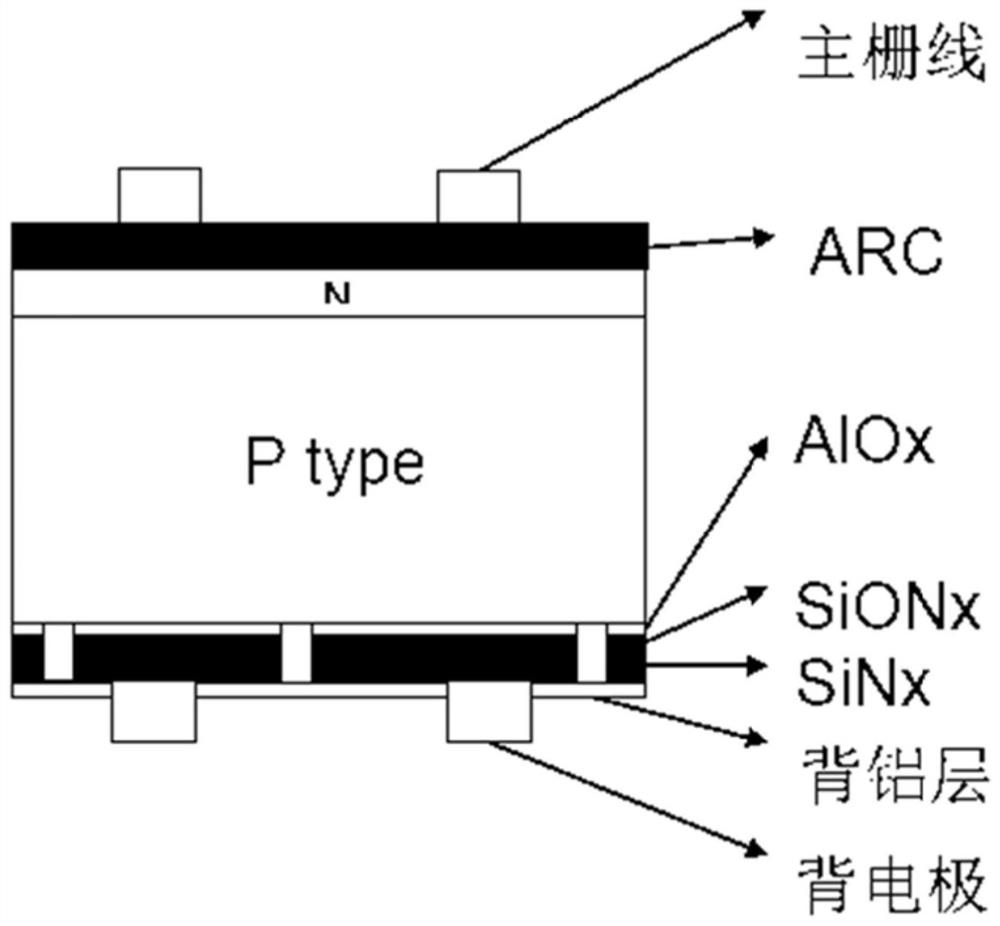

PERC crystalline silicon solar cell main grid slurry and preparation method thereof

A technology for solar cells and paste, applied in the field of solar cells, can solve the problems of high requirements on busbar printability, high productivity, fast printing speed, etc., and achieve the effects of improving cell filling factor, reducing space charge recombination, and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

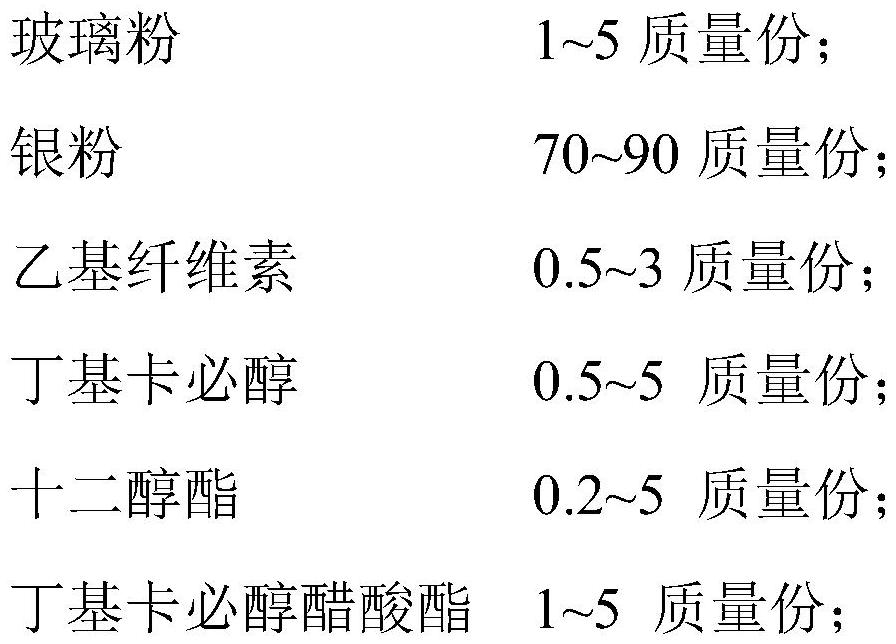

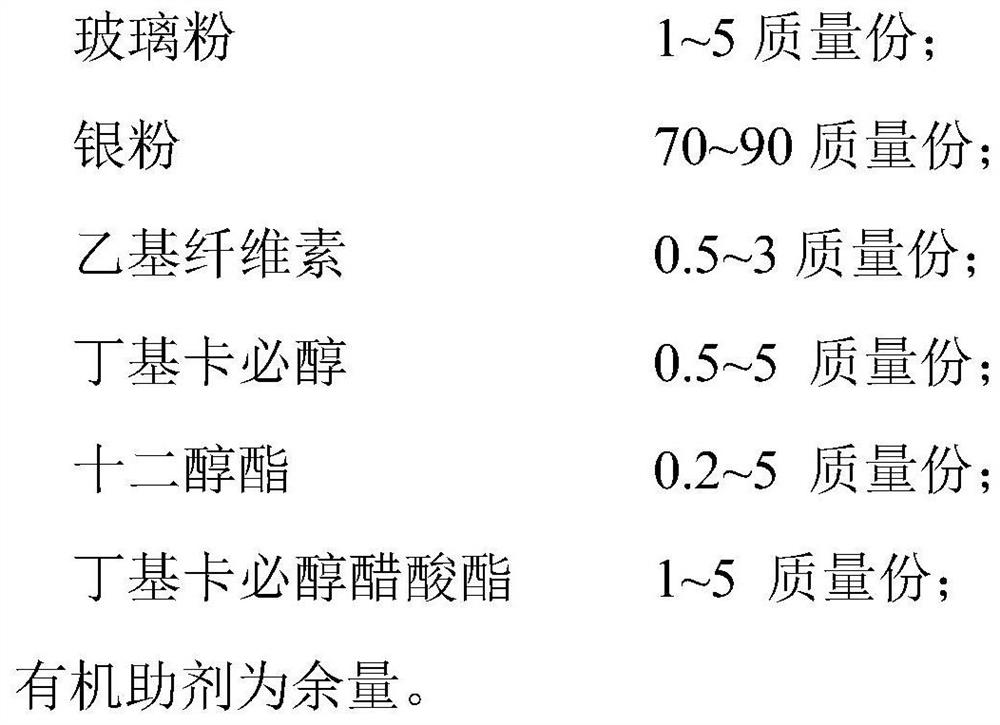

[0021] Embodiment 1: a kind of high reliability PERC crystalline silicon solar cell busbar conductive paste, the composition quality of described busbar conductive paste is such as Table 1:

[0022]

[0023]

[0024] Described glass powder composition is respectively:

[0025] One mole fraction composition of glass powder is 0.1-0.3 parts of PbO, 0.01-0.1 parts of Li 2 O, 0.01~0.1 part of Al 2 o 3 , 0.01 to 0.2 parts of ZnO, 0.05 to 0.3 parts of TiO 2 , 0.35~0.55 parts of SiO 2 , 0~0.2 parts of TeO 2 , 0~0.1 part of CeO 2 , 0-0.1 part of La 2 O, 0.05-0.2 part of MnO 2 , 0.01 to 0.3 parts of CuO;

[0026] The average particle size of the conductive phase of silver powder is between 0.2-3um, and the tap density is 2.0-5.0g / cm3;

[0027] The production process of the conductive silver paste for the busbar electrode of the PERC crystalline silicon solar cell is as follows:

[0028] Step 1: Ethyl cellulose, butyl carbitol, lauryl alcohol ester, and organic additives...

Embodiment 1

[0032] Embodiment one test electric performance is as table two:

[0033] Table II

[0034] PASTE Uoc Isc Rs. Rsh FF Eff Pull / N ref 0.677 9.880 0.00123 28.85 80.32 0.2208 1.5 Embodiment one 0.678 9.872 0.00138 111.18 80.36 0.2211 2.0

Embodiment 2

[0035] Embodiment 2: A kind of high reliability PERC crystalline silicon solar cell busbar conductive paste, the composition quality of described busbar conductive paste is such as Table 3:

[0036] Table three

[0037] Embodiment two glass powder 1.60% silver powder 86.40% Butyl Carbitol 2.90% lauryl alcohol ester 2.70% Butyl Carbitol Acetate 2.50% Ethyl cellulose 1.50% Organic additives 2.40%

[0038] Described glass powder composition is respectively:

[0039] The mole fraction composition of the glass powder is 0.1-0.3 parts of PbO, 0.01-0.1 parts of Bi 2 o 3 , 0.1 to 0.3 parts of Al 2 o 3 , 0.05 to 0.3 parts of TiO 2 , 0.01 to 0.2 parts of ZnO, 0.35 to 0.55 parts of SiO 2 , 0~0.1 WO 2 , 0~0.2 parts of TeO 2 , 0~0.1 part of CeO 2 , 0-0.1 part of La 2 O0.05~0.2 parts of MnO 2 , 0.01-0.3 parts of CuO; the average particle size of the silver powder conductive phase is between 0.2-3um, and the tap density is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com