Process for producing nan-hydroxyl kietyoite/carbon nano-pipe compound coating

A composite technology of nano-hydroxyapatite and carbon nanotubes, which is applied in the field of biomedical materials, can solve the problems of large difference in thermal expansion coefficient and weakened bonding force, and achieve the effects of reducing sintering temperature, enhancing bonding force, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

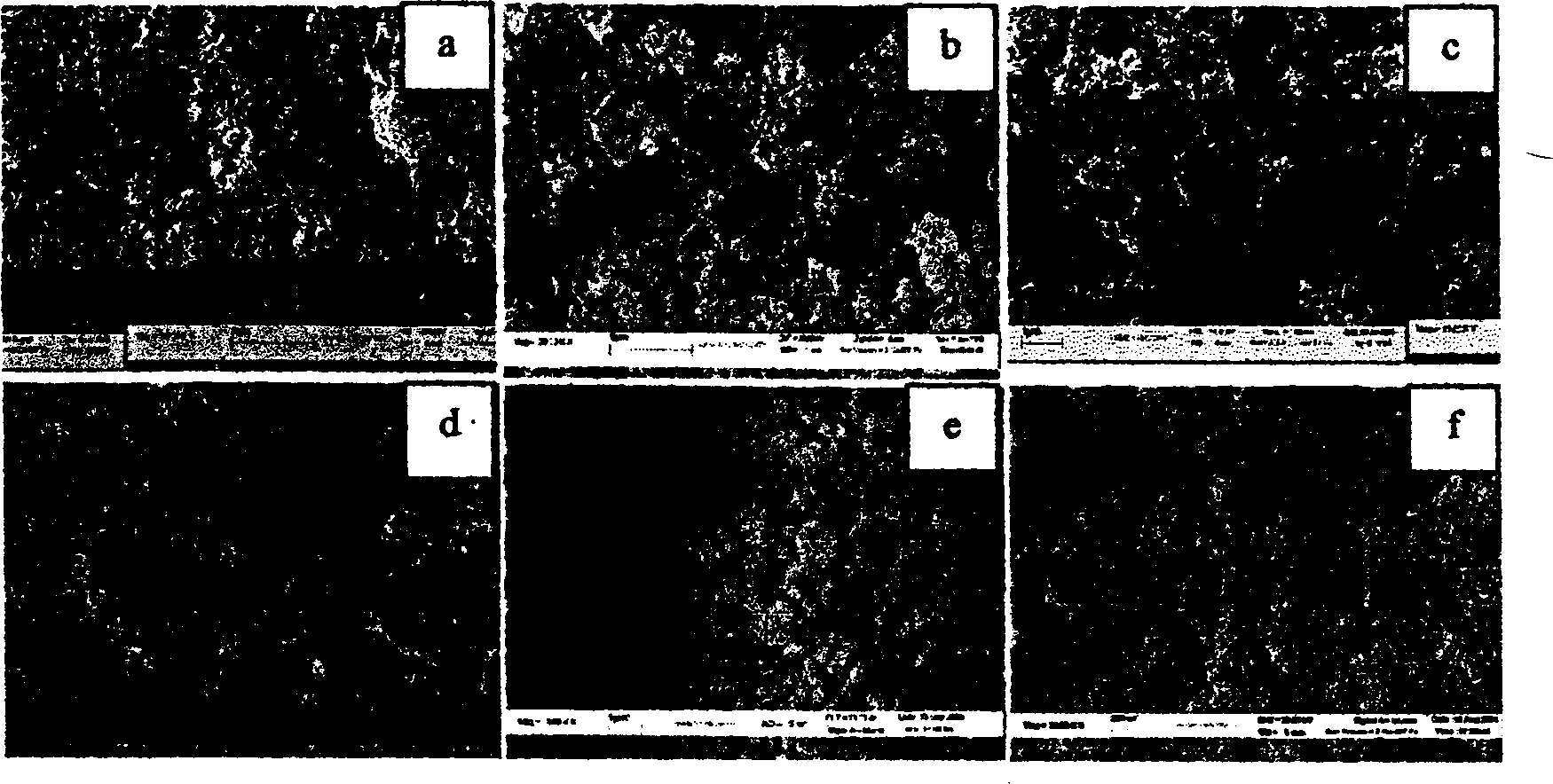

[0020] Example 1: The base material is commercial pure titanium, the sample size is 10mm×20mm×3mm, mechanically polished with sandpaper, and ultrasonically cleaned with water, acetone and ethanol once, and then immersed in 10mol / 1 NaOH solution and heat treated at 140°C 6h. After cooling, rinse with deionized water, and then place in 5% NaHCO 3 Soak in the solution for 1-10h to keep the surface neutral. Configure an electrophoretic deposition solution with a total concentration of (including HA and CNTs) 0.005g / ml with a CNTs content of 20%, and add a few drops of concentrated HNO. 3 , Adjust the pH value between 4 and 5, and the Zeta potential measured under this condition is positive, indicating that the particles are positively charged. The prepared solution is coagulated for one day to stabilize the system, ultrasonicated for 3 hours, centrifuged to separate larger particles, and then ultrasonicated for 0.5 hours for use. A circular stainless steel ring with an outer diameter ...

Embodiment 2

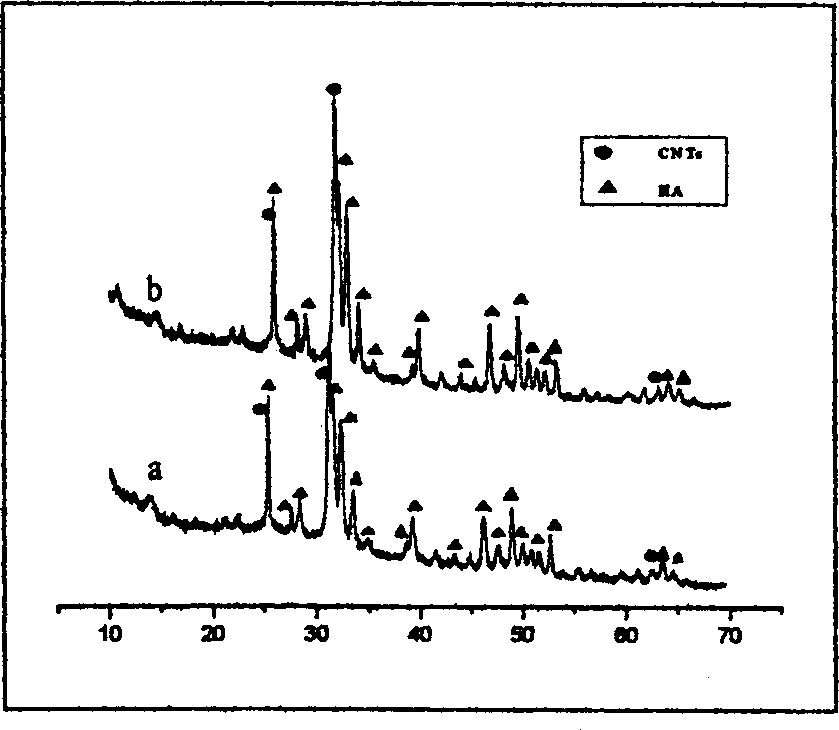

[0022] Example 2: Electrophoretic deposition conditions and electrode pretreatment are the same as in Example 1. The obtained sample was dried in air, sintered at 700°C under the protection of argon, and controlled at this temperature for 2h, and then cooled to room temperature. A uniform gray coating without cracks (see figure 1 b). The mechanical test results are listed in Table 1. The coating-titanium substrate bonding force is 34.94MP. Table 1 shows the comparison of the binding force of the composite coatings with different contents of CNTs. From the results in Table 1, it can be seen that the bonding force between the composite coating and the metal substrate has been greatly improved after adding CNTs, and there is little difference in the bonding force between the composite coating and the substrate when the CNTs content is 20% and 30%.

Embodiment 3

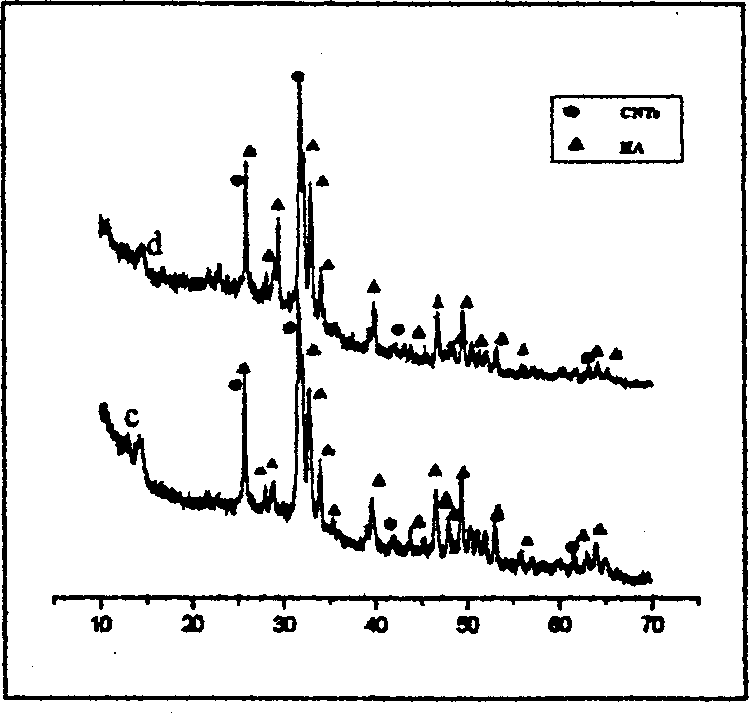

[0023] Example 3: The electrophoretic deposition conditions are the same as in Example 1, wherein the CNTs content is adjusted to 30% and finally a uniform black coating is obtained (see figure 1 c). The sample was dried in air and sintered at 700°C under the protection of argon. The temperature was controlled at this temperature for 2 hours and then cooled to room temperature. A uniform and crack-free black coating (see figure 1 d). The mechanical test results are listed in Table 1. The coating-titanium substrate bonding force is 35.44MP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com