A kind of porous composite bone cement and preparation method thereof

A technology of bone cement and dehydrating agent, used in surgical adhesives, prostheses, operations, etc., can solve the problems of ingrowth of bone cells, affecting the mechanical properties and biocompatibility of bone cement, and low interfacial adhesion, achieving Good biocompatibility and effects of biodegradability, non-immunogenic biocompatibility, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A porous composite bone cement is mainly composed of 20g powder and 10mL liquid. The powder is mainly composed of the following raw materials: PMMA 11.98g, degradable biological material 2g, barium sulfate 6g, benzoyl peroxide 0.02g , the above-mentioned raw materials are evenly mixed to obtain bone cement powder; the liquid is mainly composed of the following raw materials: methyl methacrylate 9.45ml, N,N-dimethyl-p-toluidine 0.5mL, hydroquinone 0.05mL, the above-mentioned raw materials Mix to obtain the bone cement liquid.

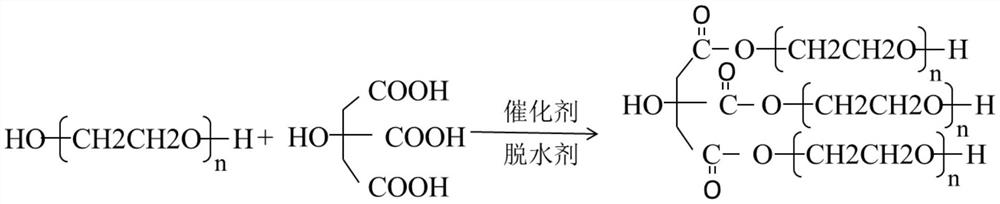

[0025] The degradable biomaterial is a copolymer with three branched structures obtained by the polymerization of polyethylene glycol and citric acid through esterification reaction, and the specific preparation method is as follows: EDCI, DMAP, citric acid, polyethylene glycol (Molecular weight is 200) mixed according to the molar ratio of 2:0.5:1:3, and dissolved in n-butanol solvent, reacted at 40 ° C for 6 hours, separated after the reaction, ...

Embodiment 2

[0028] A porous composite bone cement is mainly composed of 20g powder and 10mL liquid. The powder is mainly composed of the following raw materials: PMMA 10.98g, degradable biological material 3g, barium sulfate 6g, benzoyl peroxide 0.02g , the above-mentioned raw materials are evenly mixed to obtain bone cement powder; the liquid is mainly composed of the following raw materials: methyl methacrylate 9.3ml, N,N-dimethyl-p-toluidine 0.5mL, hydroquinone 0.2mL, the above-mentioned raw materials Mix to obtain the bone cement liquid.

[0029] The degradable biological material is a copolymer with three branched structures mainly obtained by the polymerization of polyethylene glycol and citric acid through an esterification reaction, and the specific preparation method is as follows: N,N-dicyclohexylcarbodiimide , tetrabutyl titanate, citric acid, polyethylene glycol (molecular weight 400) were mixed according to the molar ratio of 2:0.5:1:3, and dissolved in n-butanol solvent, rea...

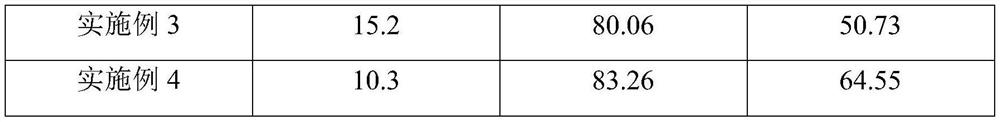

Embodiment 3

[0032] A porous composite bone cement is mainly composed of 20g powder and 10mL liquid. The powder is mainly composed of the following raw materials: PMMA 9.98g, degradable biological material 4g, barium sulfate 6g, benzoyl peroxide 0.02g , the above-mentioned raw materials are evenly mixed to obtain bone cement powder; the liquid is mainly composed of the following raw materials: methyl methacrylate 9.945ml, N,N-dimethyl-p-toluidine 0.05mL, hydroquinone 0.005mL, the above-mentioned raw materials Mix to obtain the bone cement liquid.

[0033] The degradable biological material is a copolymer with three branched structures mainly obtained by the polymerization of polyethylene glycol and citric acid through esterification reaction, and the specific preparation method is as follows: EDCI, tetraisopropyl titanate, citric acid , polyethylene glycol (molecular weight: 600) is mixed according to the molar ratio of 2:0.5:1:3, and dissolved in n-butanol solvent, reacted at 40 ° C for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com