Silane cross-linking modified ultra-high molecular weight polyethylene fiber preparation method

An ultra-high molecular weight, polyethylene fiber technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of poor continuity and damage to the mechanical properties of UHMWPE fibers, and achieve the effects of low modification cost, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

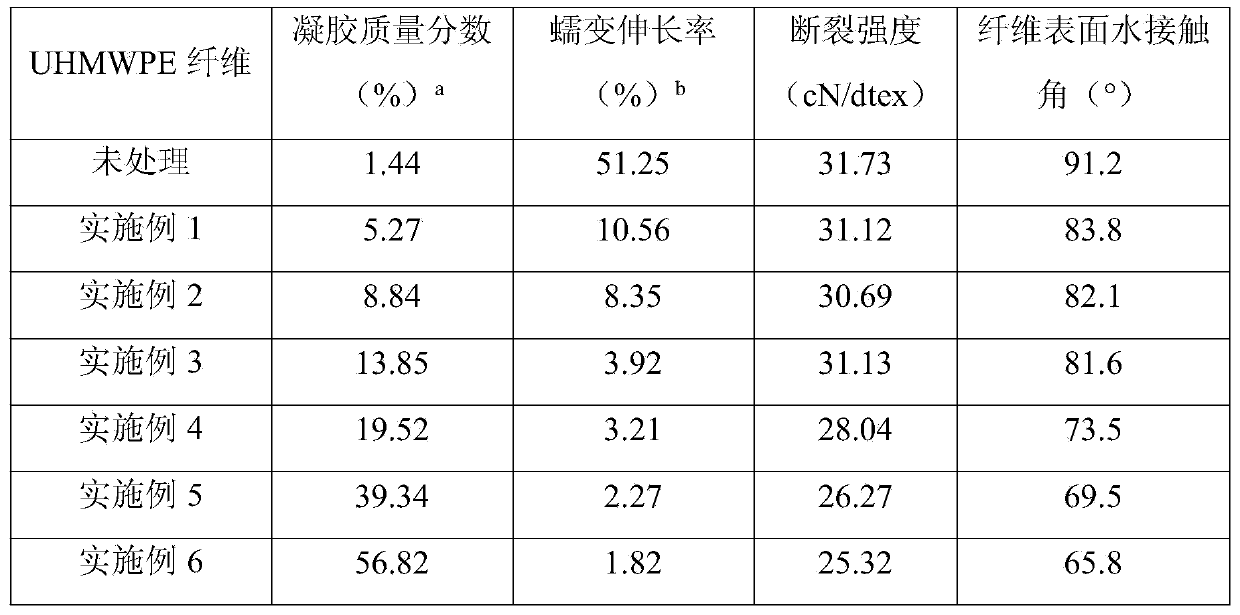

Examples

Embodiment 1

[0026] Using xylene as a solvent, the modified solution was prepared according to the mass concentration of benzoyl peroxide and vinyltrimethoxysilane at 0.08% and 2%, respectively, and the undried UHMWPE fiber was placed in a bath ratio of Ultrasonic treatment was carried out in a 20:1 modified solution for 6 minutes, the ultrasonic treatment temperature was 30°C, and the ultrasonic frequency was 35kHz. After taking out and drying, three-stage thermal stretching was carried out at 100°C, 120°C and 130°C respectively. The total stretching The multiple is 48 times, and the relative humidity of the ambient air is 60% during stretching, and the UHMWPE fiber modified by silane crosslinking is obtained.

Embodiment 2

[0028] Using dichloromethane as a solvent, the mass concentration of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and vinyl tri-tert-butylperoxysilane is 0.5% and 5% respectively Configure the modified solution, extract and remove the undried fiber solvent

[0029] The UHMWPE fibers were placed in a modified solution with a bath ratio of 25:1 and subjected to ultrasonic treatment for 5 minutes. The ultrasonic treatment temperature was 30°C and the ultrasonic frequency was 35kHz. Stretching, the total stretching ratio is 45 times, the ambient air relative humidity is 70% during stretching, and the UHMWPE fiber modified by silane crosslinking is obtained.

Embodiment 3

[0031]Using xylene as a solvent, the modified solution was prepared according to the mass concentration of benzoyl peroxide and vinyltriethoxysilane at 0.2% and 6%, respectively, and the undried UHMWPE fiber was placed in the bath ratio after the fiber solvent was removed by extraction. Ultrasonic treatment for 4 minutes in a modified solution of 20:1, the ultrasonic treatment temperature is 40°C, and the ultrasonic frequency is 35kHz. After taking out and drying, three-stage thermal stretching is carried out at 100°C, 120°C and 130°C respectively. The total stretching The multiple is 45 times, and the relative humidity of the ambient air is 65% during stretching, and the UHMWPE fiber modified by silane crosslinking is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com