Injection-molding polyamide composite material and preparation method thereof

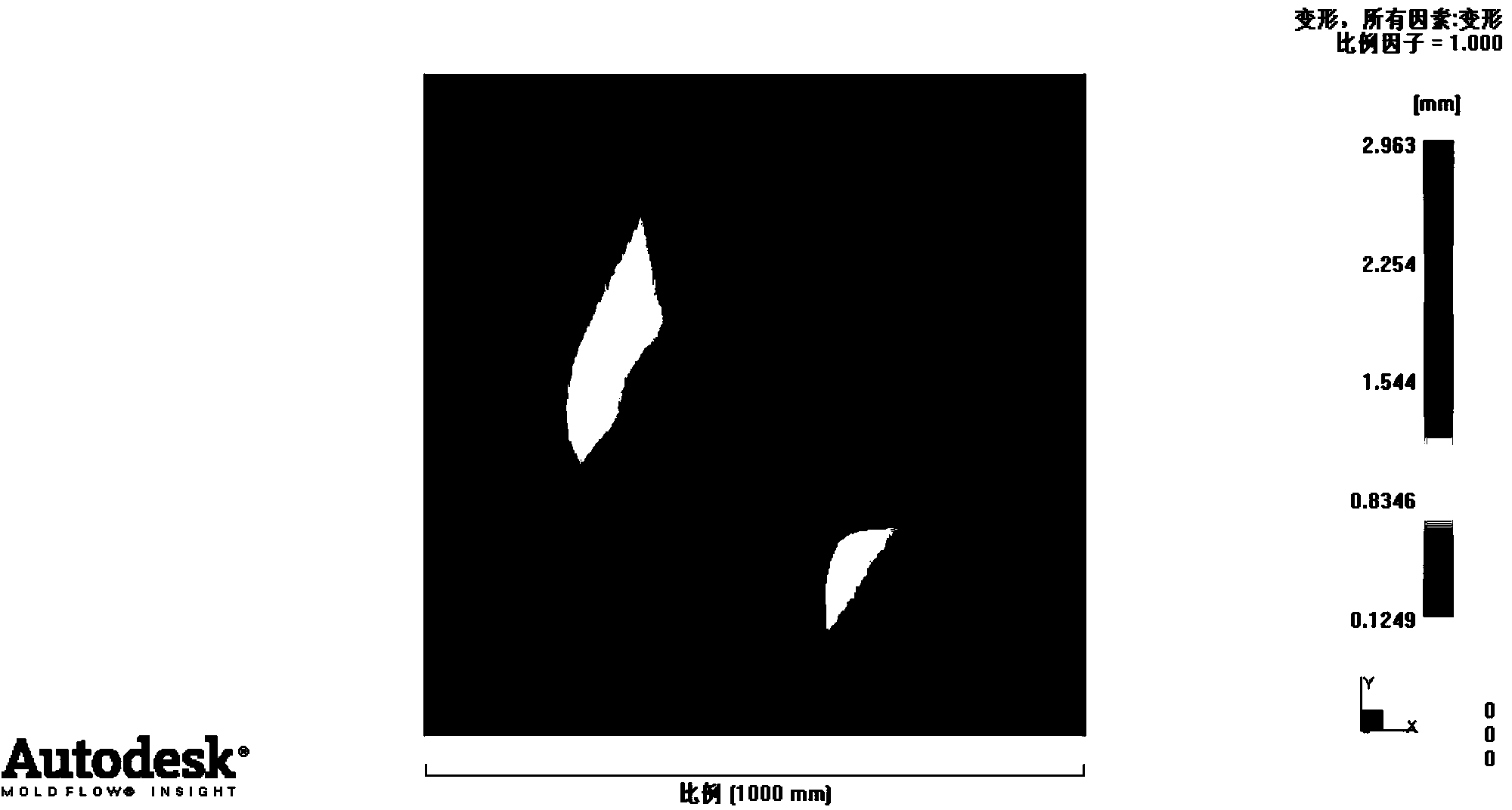

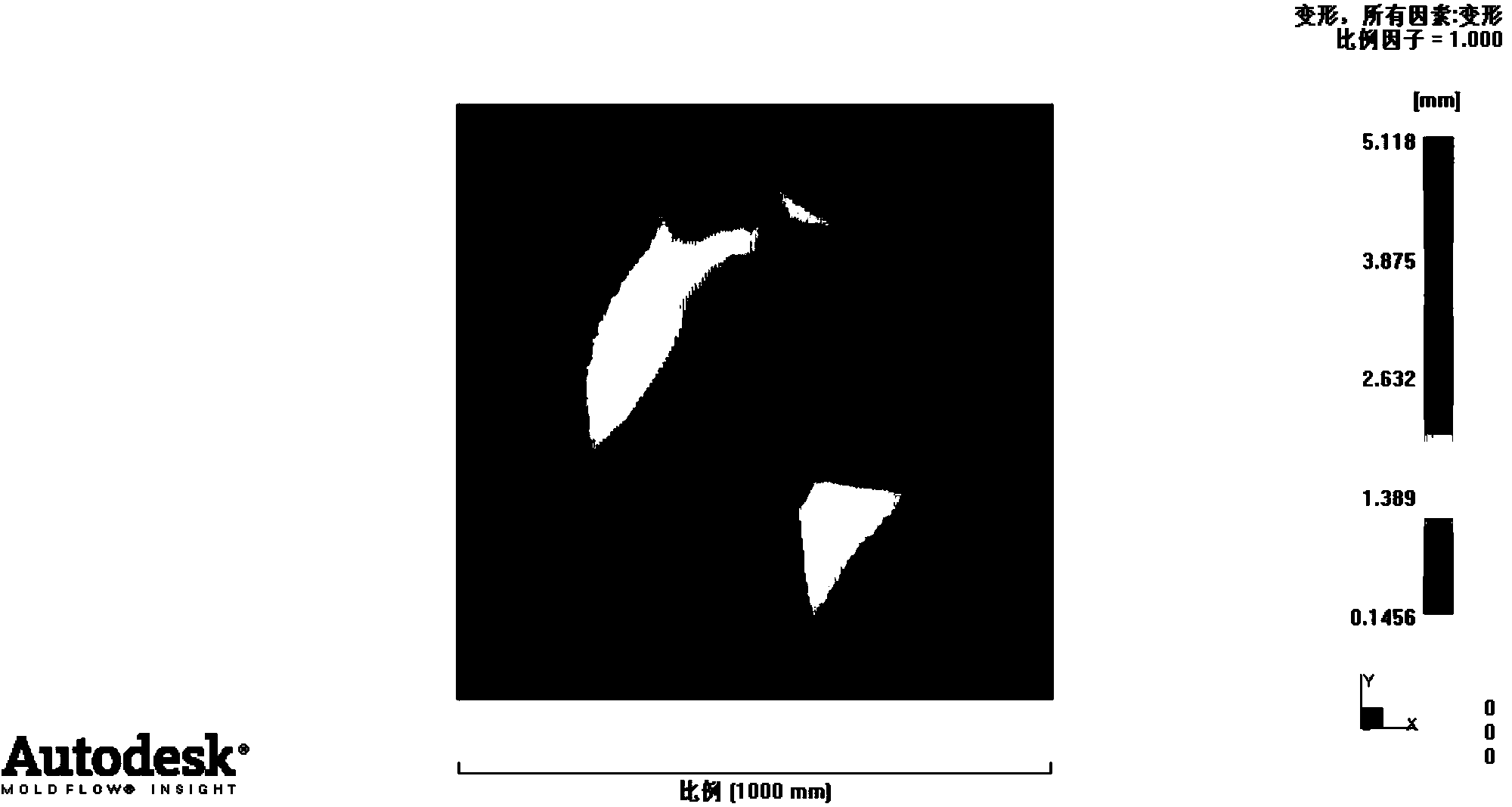

A composite material and polyamide technology, applied in the field of materials, can solve the problems of poor appearance and warpage deformation of parts, and achieve the effect of improving the appearance and reducing the degree of warpage deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high appearance, low warpage glass fiber reinforced polyamide composite material comprising, by weight percent:

[0030] PA6: 83.2%, chopped glass fiber: 15%, antioxidant: 1098 (0.1%), 168 (0.1%), nucleating agent: 0.1%, black mother: 1%; lubricant: 0.5%; PA6 relative The viscosity is 2.4; the chopped glass fiber is 10 μm; the nucleating agent is a low-molecular ionomer; black masterbatch, no carrier black masterbatch, the carbon content is 92%; the lubricant is silicone.

[0031] High appearance, low warpage glass fiber reinforced polyamide composites, proceed as follows:

[0032] (1) Premixing: Add PA6, antioxidant, nucleating agent, black masterbatch and lubricant into the blender according to the above ratio, and blend for 5 minutes;

[0033] (2) Pelletizing: Add the homogeneously mixed materials in step (1) into the main feeding hopper of the twin-screw extruder, add glass fiber into the side feeding hopper, control the glass fiber content, and melt and extrude ...

Embodiment 2

[0036] A high appearance, low warpage glass fiber reinforced polyamide composite material comprising, by weight percent:

[0037] PA6: 68.2%, chopped glass fiber: 30%, antioxidant: 1098 (0.1%), 168 (0.1%), nucleating agent: 0.1%, black mother: 1%; lubricant: 0.5%; PA6 relative The viscosity is 2.4; the chopped glass fiber is 10 μm; the nucleating agent is a low-molecular ionomer; black masterbatch, no carrier black masterbatch, the carbon content is 92%; the lubricant is silicone.

[0038] High appearance, low warpage glass fiber reinforced polyamide composites, proceed as follows:

[0039] (1) Premixing: Add PA6, antioxidant, nucleating agent, black masterbatch and lubricant into the blender according to the above ratio, and blend for 5 minutes;

[0040] (2) Pelletizing: Add the homogeneously mixed materials in step (1) into the main feeding hopper of the twin-screw extruder, add glass fiber into the side feeding hopper, control the glass fiber content, and melt and extrude ...

Embodiment 3

[0043] A high appearance, low warpage glass fiber reinforced polyamide composite material comprising, by weight percent:

[0044] PA6: 68.2%, chopped glass fiber: 10%, modified calcium carbonate: 20%, antioxidant: 1098 (0.1%), 168 (0.1%), nucleating agent: 0.1%, black masterbatch: 1%; Lubricant: 0.3%; relative viscosity of PA6 is 2.4; chopped glass fiber 10μm; calcium carbonate is 800 mesh; nucleating agent is low molecular ionomer; for silicone.

[0045] Preparation of modified calcium carbonate: calcium carbonate and silane coupling agent are added in the blender, and blended for 10 min at 50° C. to obtain modified calcium carbonate. The amount of silane coupling agent added is 0.5% of the weight of calcium carbonate; Apparently, low warpage glass fiber reinforced polyamide composites, proceed as follows:

[0046] (1) Premixing: Add PA6, modified calcium carbonate, antioxidant, nucleating agent, black masterbatch and lubricant into the blender according to the above ratio,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com