High-plasticity and high-strength cast beryllium-aluminum alloy and preparation method thereof

A beryllium-aluminum alloy and high-strength technology, applied in the field of non-ferrous metal alloy preparation, can solve the problems of difficult casting defects, low strength, poor plasticity of beryllium-aluminum alloy, and achieve the effects of improving plasticity, low cost, and improving alloy hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-plasticity, high-strength cast beryllium aluminum alloy, comprising: beryllium (Be) 60%, aluminum (Al) 38%, nickel (Ni) 1.0%, lithium (Li) 0.5%, germanium (Ge) 0.5% according to mass percentage %, and the rest are unavoidable impurities.

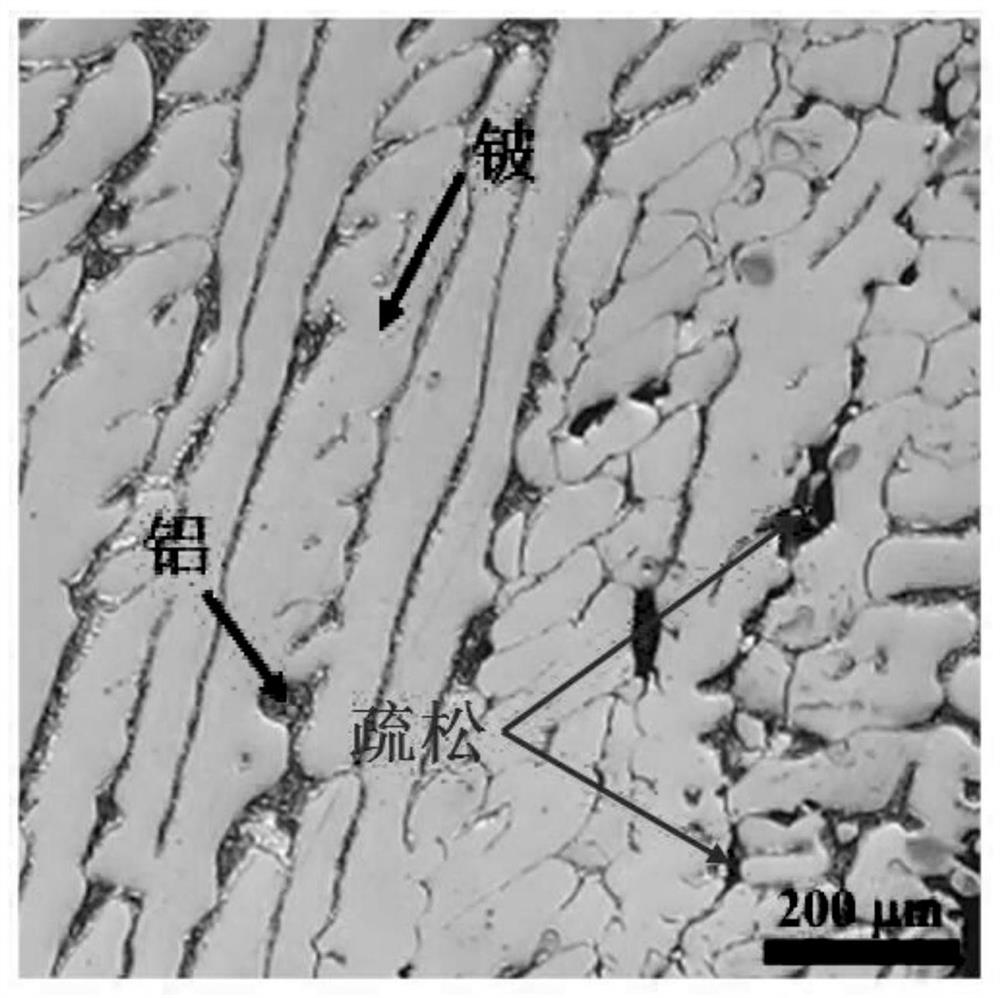

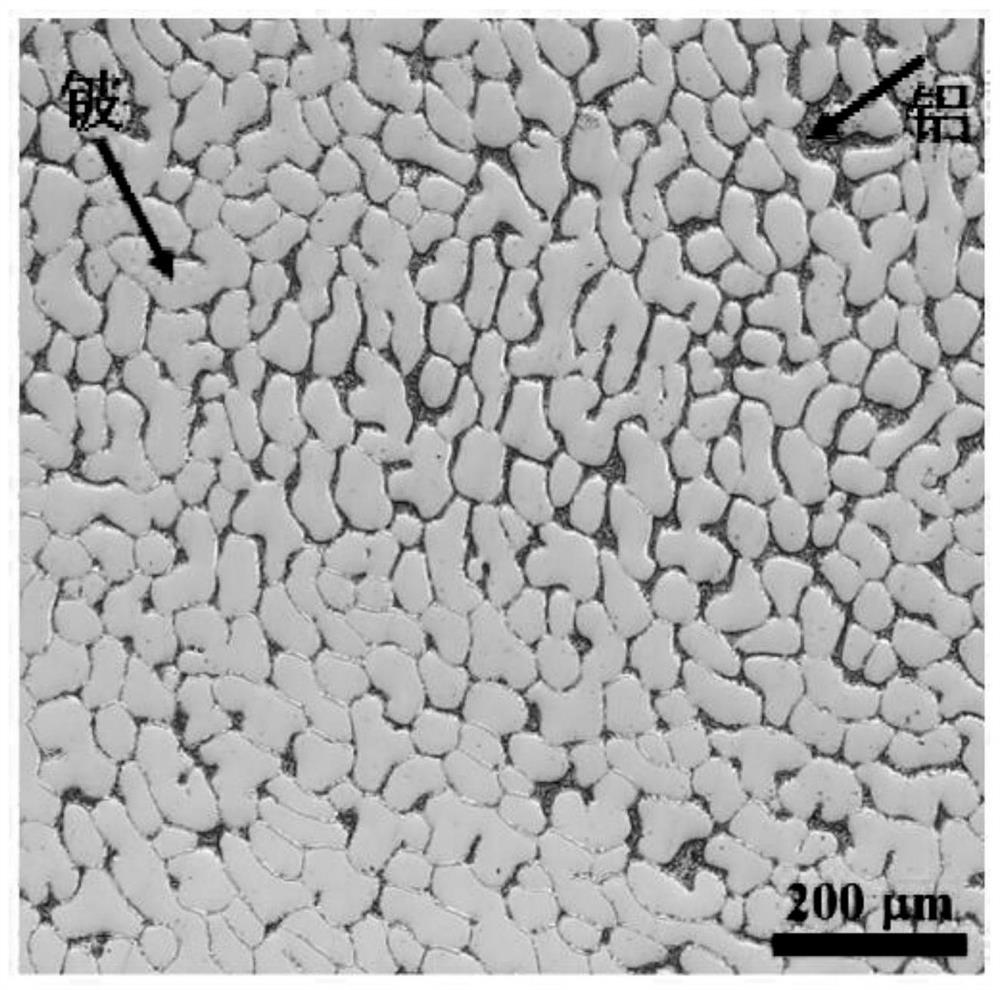

[0034] A method for preparing the above-mentioned beryllium aluminum alloy, comprising the following steps: vacuuming the cavity of the vacuum induction melting furnace to 2.0×10 -2 After the Pa is filled with high-purity argon gas of 0.1 standard atmospheric pressure, the prepared alloy raw materials are placed in a graphite crucible and preheated at 200°C for 10 minutes. Turn on the power to raise the temperature of the raw material to 1430°C and keep it warm for 15 minutes, then cool it down to 1380°C and keep it warm for 4 minutes, and then pour it into an ingot at 1360°C. After coming out of the furnace, the alloy ingot was homogenized and heat-treated in argon at 560°C for 24 hours, and then water-quenched at room temper...

Embodiment 2

[0040] A high-plasticity, high-strength cast beryllium aluminum alloy, comprising: beryllium (Be) 65%, aluminum (Al) 33%, nickel (Ni) 0.7%, lithium (Li) 0.3%, germanium (Ge) 1.0% by mass percentage %, and the rest are unavoidable impurities.

[0041] A method for preparing the above-mentioned beryllium-aluminum alloy, comprising the steps of: evacuating the cavity of a vacuum induction melting furnace to 1.5×10- 2After the Pa is filled with high-purity argon gas of 0.2 standard atmospheric pressure, the prepared alloy raw materials are placed in a graphite crucible and preheated at 150°C for 30 minutes. Turn on the power to raise the temperature of the raw material to 1450°C and keep it warm for 12 minutes, then cool it down to 1360°C and keep it warm for 6 minutes, and then pour it into an ingot at 1350°C. After being released from the furnace, the alloy ingot was homogenized and heat-treated in argon at 540°C for 36 hours, and then water-quenched at room temperature. Carry...

Embodiment 3

[0046] A high-plasticity, high-strength cast beryllium-aluminum alloy, composed according to mass percentage: beryllium (Be) 56%, aluminum (Al) 42%, nickel (Ni) 0.8%, lithium (Li) 0.6%, germanium (Ge) 0.6% %, and the rest are unavoidable impurities.

[0047] A method for preparing the above-mentioned beryllium-aluminum alloy, comprising the following steps: the method for preparing the above-mentioned high-strength, high-plasticity cast beryllium-aluminum alloy is as follows: evacuate the cavity of the vacuum induction melting furnace to 2.0×10- 2 After Pa, it is filled with high-purity argon gas of 0.4 standard atmospheric pressure, and the prepared alloy raw materials are placed in a graphite crucible and preheated at 180°C for 20 minutes. Turn on the power to raise the temperature of the raw material to 1400°C and keep it warm for 20 minutes, then cool it down to 1350°C and keep it warm for 8 minutes, and then pour it into an ingot at 1340°C. After coming out of the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com