Gasification cracking device based on electric induction heating and method for preparing sulfur gas

A technology of cracking device and gasification cracking furnace is applied in the fields of preparing high-temperature sulfur gas and gasification cracking device, which can solve the problems of external heating and the like, and achieve the effect of simple and perfect structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Utilize the gasification and cracking device based on induction heating in the present invention to gasify and produce sulfur gas, the process is as follows:

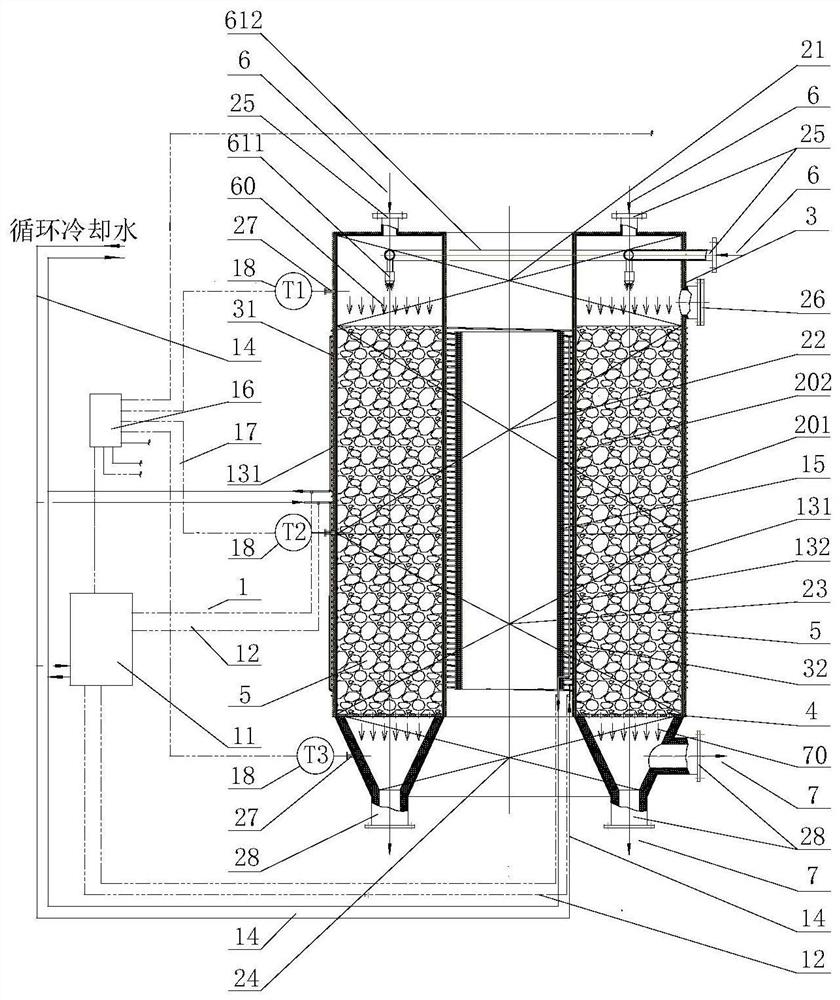

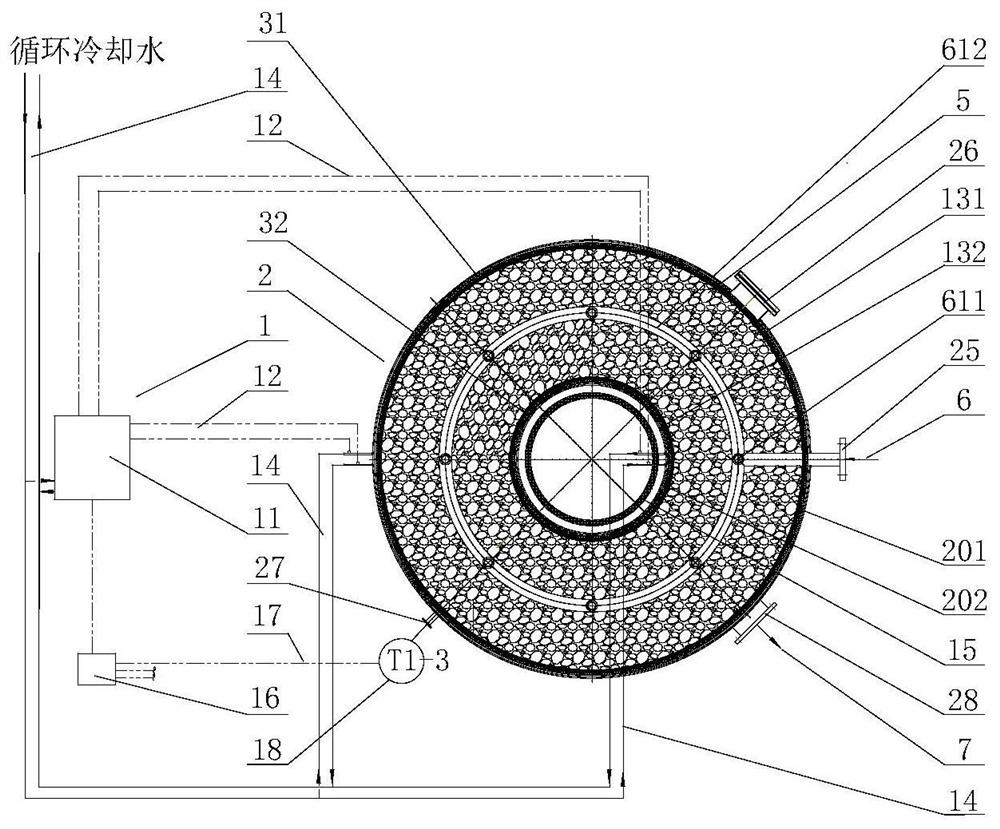

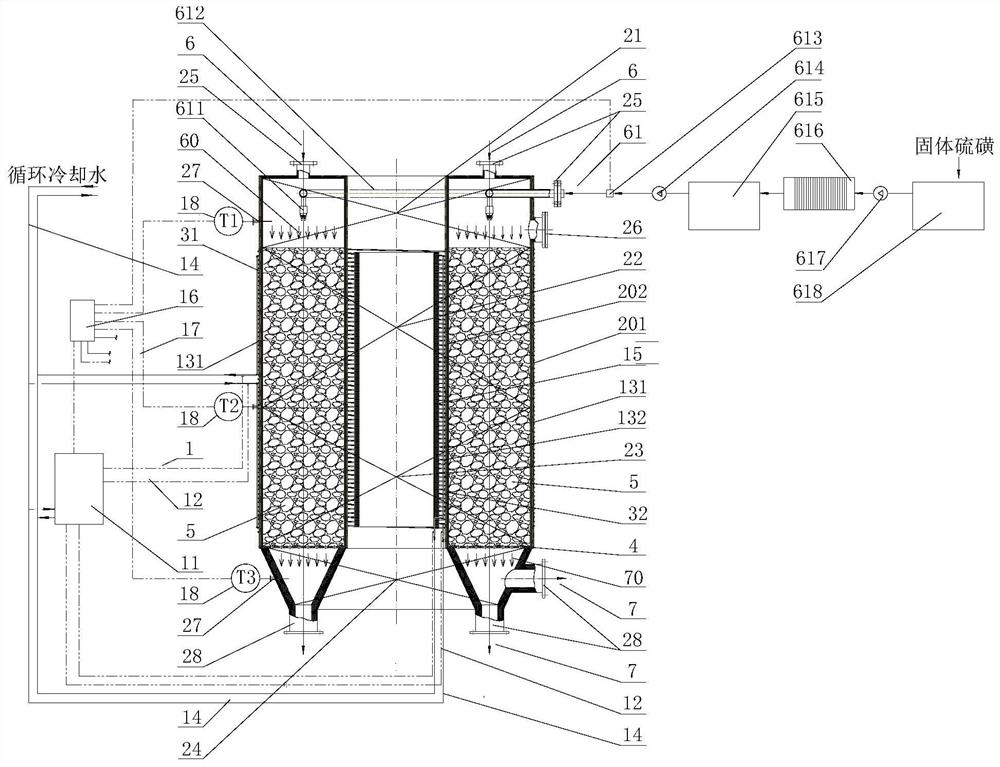

[0083] Such as image 3 , Figure 4 As shown, in this embodiment, solid sulfur is used as a raw material, which is indirectly heated and melted into liquid sulfur by a steam coil, and then sent to a sulfur filter 616 by a crude sulfur pump 617 to filter and remove solid and organic impurities. After filtering, the refined liquid sulfur is put into a refined sulfur storage Store in tank 615, then adjust and control the amount of sulfur through refined sulfur pump 614 and flow meter 613, and send the liquid material inlet 61 of gasification cracking furnace shell 2, directly atomized by atomizing nozzle 611, and pass through the external induction coil of gasification cracking furnace 131. Induction and heating of the inner induction coil 132 work together to gasify to obtain high-temperature sulfur gas.

[0084]...

Embodiment 2

[0089] Such as Figure 5 , Figure 6 As shown, in this embodiment, the outer cylinder body 201 and the inner cylinder body 202 of the gasification cracking furnace are magnetically conductive heating elements, and their materials are chromium-molybdenum-nickel metal alloy, silicon carbide, graphite-silicon carbide composite material, silicon carbide-dicarbonate Molybdenum silicide composite material, silicon dioxide-molybdenum disilicide composite material, silicon carbide-zirconia composite material and other high temperature resistant magnetic materials, the heat transfer carrier 5 is made of honeycomb block molybdenum disilicide, vermiculite, One of silicon carbide, alumina ceramics and other high temperature resistant ceramics.

[0090] Using solid sulfur as the raw material, the solid sulfur particles enter the storage bin 626 for buffering, and after being stabilized by the feeder 625 and weighing equipment 624, they are sent to the screw extruder 623, and the solid sul...

Embodiment 3

[0096] Such as Figure 7 , Figure 8As shown, in this embodiment, liquid sulfur is used as a raw material, and the molten sulfur tank 618 uses heat conduction oil for indirect heating and heat preservation to maintain molten liquid sulfur, and the liquid sulfur is blown and atomized by pumping nitrogen; the outer cylinder 201 and the inner cylinder of the gasification cracking furnace 202 selects one of non-magnetic conductive ordinary ceramics, glass fiber reinforced plastics, and quartz glass. According to the needs of processing capacity and heating power, a plurality of small cylindrical magnetic heating elements 8 are arranged in the inner cavity. Silicon carbide, a combination of graphite and silicon carbide, silicon carbide-molybdenum disilicide composite material, silicon dioxide-molybdenum disilicide composite material, silicon carbide-zirconia composite material and other high temperature resistant magnetic materials, separator 4 Porous high-temperature resistant ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com