Gasification cracking device based on microwave heating and method for rapidly preparing sulfur gas

A cracking device and microwave heating technology, applied in chemical instruments and methods, sulfur preparation/purification, inorganic chemistry, etc., can solve the problems of small processing scale, inability to realize large-scale industrial application, complex structure, etc., and achieve fast reaction speed, Simple structure and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Utilize the gasification and cracking device based on microwave heating in the present invention to gasify and produce sulfur gas, the process is as follows:

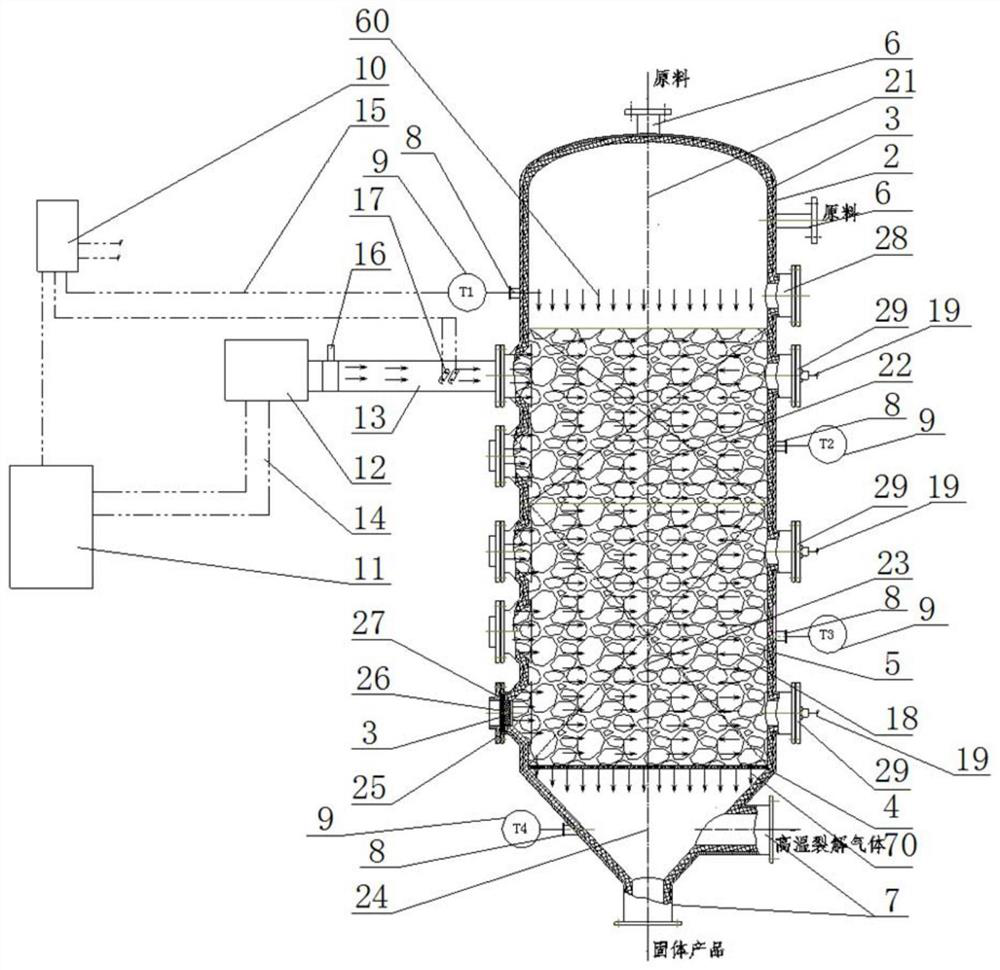

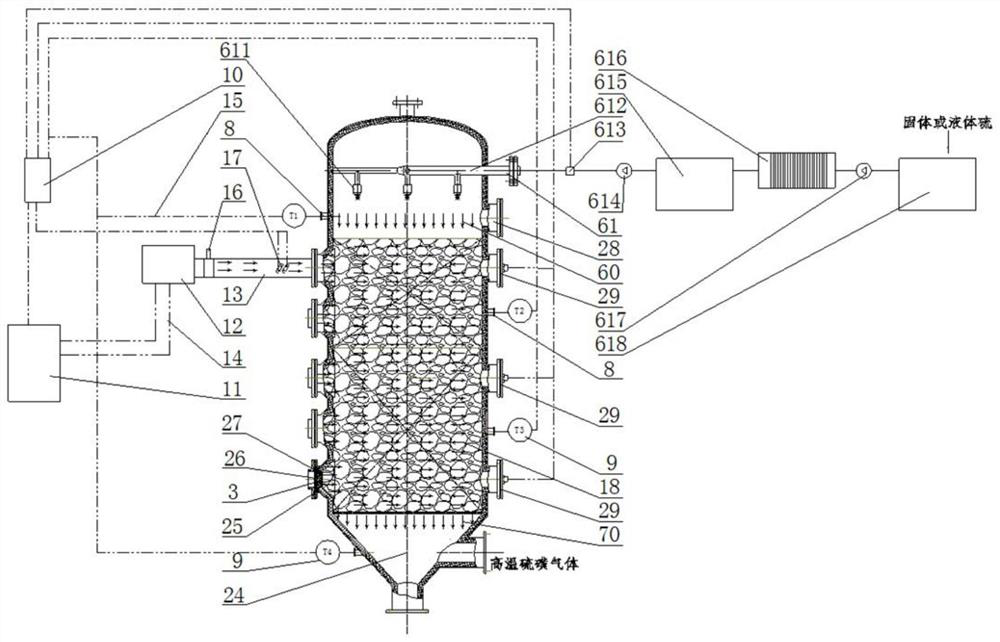

[0074] Such as image 3 , Figure 4 As shown, in this embodiment, solid sulfur is used as a raw material, which is indirectly heated and melted into liquid sulfur by a steam coil, and then sent to a sulfur filter 616 by a crude sulfur pump 617 to filter and remove solid and organic impurities. After filtering, the refined liquid sulfur is put into a refined sulfur storage Store in tank 615, then adjust and control the amount of sulfur through refined sulfur pump 614 and flow meter 613, and send the liquid material inlet 61 of gasification cracking furnace shell 2, directly atomized by atomizing nozzle 611, and pass through gasification cracking furnace shell 2 Microwave heating gasification to obtain high temperature sulfur gas.

[0075] Gasification and cracking furnace shell 2 is made of SS304 stainless steel...

Embodiment 2

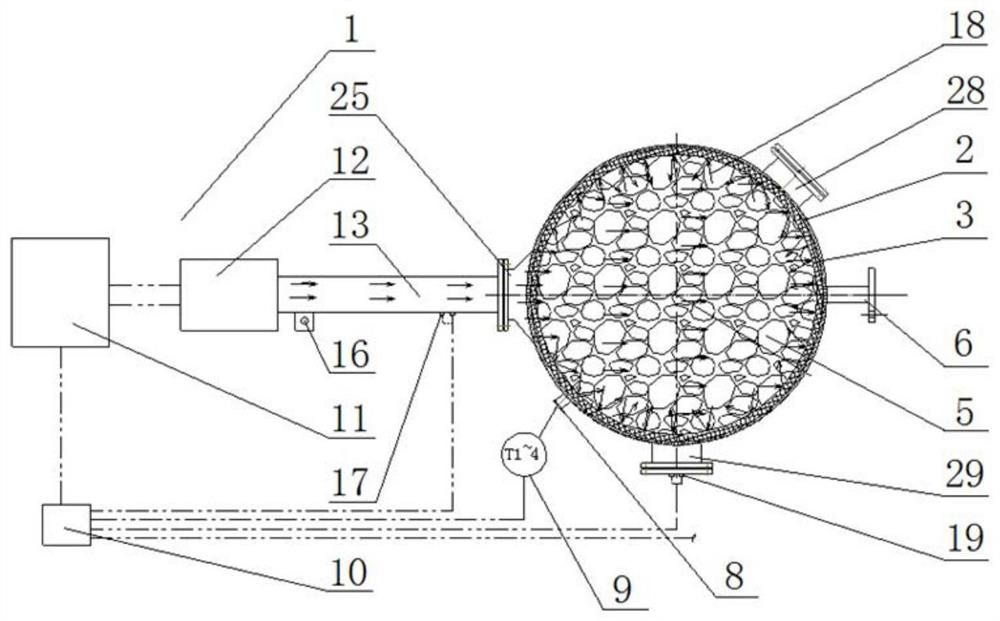

[0080] Such as Figure 5 , Figure 6 As shown, in this embodiment, liquid sulfur is used as a raw material, and the molten sulfur tank 618 uses heat conduction oil for indirect heating and heat preservation to maintain the molten liquid sulfur. The atomization of liquid sulfur uses nitrogen to assist blowing and atomization, and the shell 2 of the gasification cracking furnace is made of ordinary carbon steel. , the divider 4 adopts a porous ceramic plate, and the heating carrier 5 adopts an integral block hole silicon carbide absorbing material with a pore diameter of 3-15mm. Sulfur liquid or gas passes through the hole of the silicon carbide block, and the microwave acts on the block to make the whole block When the body temperature rises, the sulfur material contacts the block holes to absorb the heat of the block, and is heated and gasified and cracked. Seven 100kW, 915MHz microwave generation systems 1 are used for the gasification chamber 22, five 100kW, 915MHz microwav...

Embodiment 3

[0085] Such as Figure 7 , Figure 8 As shown, in this embodiment, the gasification and cracking furnace shell 2 is provided with a liner 20 made of ceramic or silicon carbide. Using solid sulfur as the raw material, the solid sulfur particles enter the storage bin 626 for buffering, and after being stabilized by the feeder 625 and weighing equipment 624, they are sent to the screw extruder 623, and the solid sulfur is melted by electric heating on the screw shell It is liquid sulfur, squeezed into the connecting pipe assembly 622, and then distributed to the lower liquid distributor 621. The liquid distributor 621 adopts the liquid distribution pipe type, which is composed of multiple concentric rings and communicates with the connecting pipe assembly 622. The bottom of the liquid distributor 621 is evenly distributed with 1-6mm liquid spray holes, relying on the screw extruder The 623 extrusion pressure sends the molten liquid sulfur into the gasification cracking furnace,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com