Degradable polymer capable of being used for wound dressing, preparation method of degradable polymer, and wound dressing

A technology for degrading polymers and wound dressings, which is applied in applications, drug delivery, and pharmaceutical formulations. It can solve problems such as inability to meet dynamic movement requirements, incomplete polymerization of toxic monomers, and weak tissue adhesion, and achieve benefits for wounds. Repair, easy mass preparation and storage, short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of degradable polymer that can be used for wound dressing is prepared according to the following steps:

[0048] Vacuumize the reaction bottle, bake it with nitrogen, repeat three times to remove water, add 2g of dihydroxy PEG (molecular weight is 1000g / mol), 0.6g of GA, 5g of LA, vacuumize and pass nitrogen to keep the reaction bottle anaerobic and water-free environment, add the solvent toluene and the catalyst stannous octoate, the amount of the catalyst is 1% (molar ratio) of the total amount of PEG, and the temperature is raised to 110° C. for 10 h.

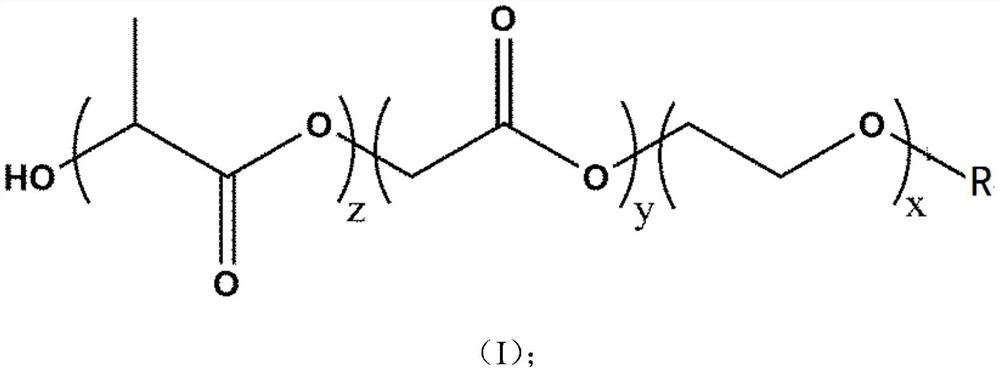

[0049] After the reaction, extract the toluene solvent, add chloroform to dissolve, then pour into a large amount of glacial ether, and settle to obtain a polymer. Place in a vacuum oven to remove residual ether. The obtained product structure is shown in formula (A2).

[0050]

Embodiment 2

[0052] A kind of degradable polymer that can be used for wound dressing is prepared according to the following steps:

[0053]Vacuumize the reaction bottle, bake it with nitrogen, repeat three times to remove water, add 4g of dihydroxy PEG (molecular weight: 2000g / mol), 3g of GA, 1.5g of LA, and evacuate with nitrogen to keep the reaction bottle free of oxygen and water. environment, the solvent toluene and the catalyst diethyl zinc were added through a syringe, the amount of the catalyst was 1% (molar ratio) of the total amount of PEG, and the temperature was raised to 110° C. for 10 h.

[0054] After the reaction, extract the solvent toluene, add chloroform to dissolve, pour into glacial ether, and settle to obtain a polymer. Place in a vacuum oven to remove ether. The obtained product structure is identical to that of Example 1.

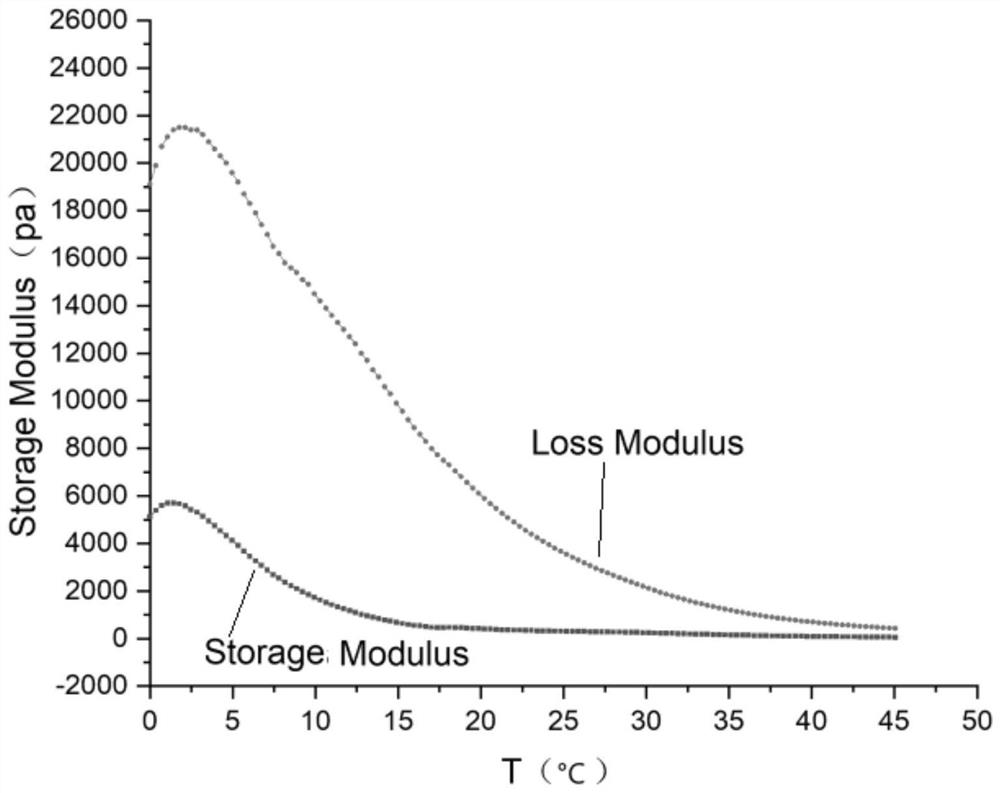

[0055] Rheometer test results are as follows figure 1 As shown, the loss modulus value is significantly higher than the storage modulus, which...

Embodiment 3

[0057] A kind of degradable polymer that can be used for wound dressing is prepared according to the following steps:

[0058] The reaction bottle is vacuum-baked, nitrogen-filled, and repeated three times to remove water, and monomethyl mPEG (molecular weight is 750g / mol) 4.6g, GA 5.6g, LA 2.8g are added, and vacuum-filled nitrogen is used to keep the reaction bottle without In an oxygen-free environment, the solvent toluene and the catalyst 1,8-diazacycloundecene were added through a syringe. The catalyst dosage was 0.5% (molar ratio) of the total amount of PEG, and the temperature was raised to 125° C. for 12 hours.

[0059] After the reaction, extract the solvent toluene, add chloroform to dissolve, pour into glacial ether, and settle to obtain a polymer. Place in a vacuum oven to remove residual ether. The structure of the obtained product is shown in formula (A1).

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com