Integrated bearing bush spraying process equipment and machining method

A technology for process equipment and bearing bushes, which is applied in the field of integrated bearing bush spraying process equipment and processing, can solve the problems of cumbersome bearing bush spraying process steps, contamination of the bearing bush spraying working surface, occupation of more workplaces, etc., so as to reduce the possibility of being polluted. , The effect of reducing site costs and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

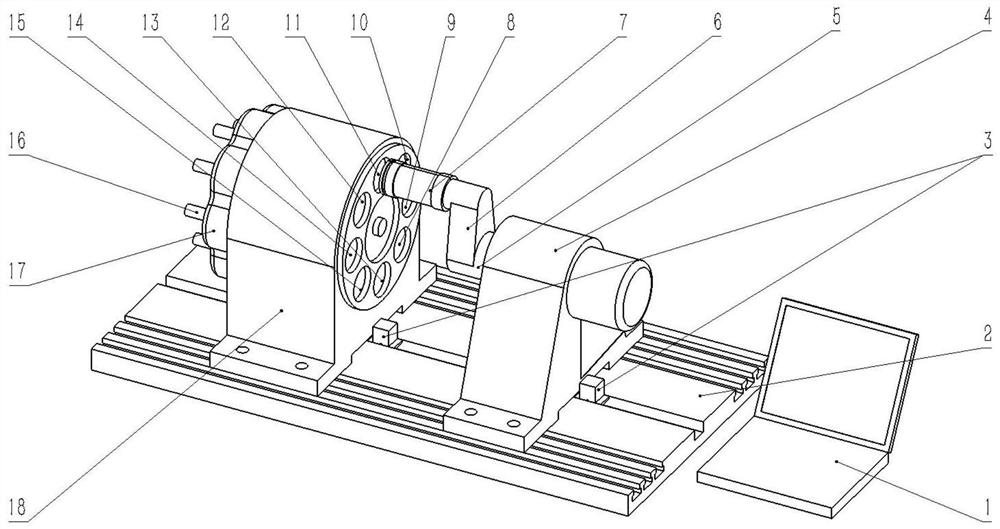

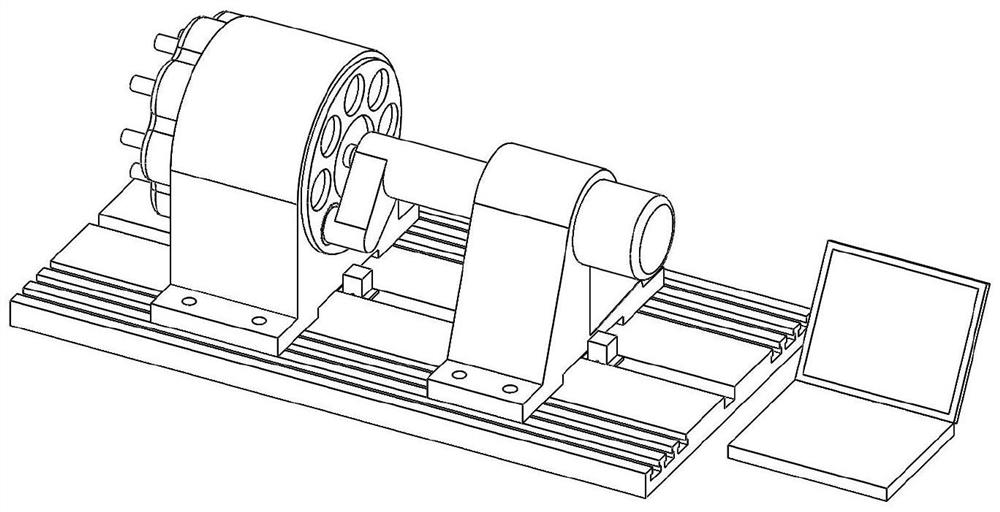

[0078] Such as Figure 1 to Figure 3An integrated bearing bush spraying process equipment is shown, including: computer 1, track 2, displacement adjustment device 3, bearing bush moving device, functional area device and functional area auxiliary device 17; displacement adjusting device 3, bearing bush moving device, function The area device and the functional area auxiliary device 17 are connected to the computer 1, and a plurality of rails 2 are arranged on the upper side of the bottom substrate, and the displacement adjustment device 3 is slidably installed in the middle of the rails 2. 2. The displacement adjustment device 3 is respectively connected to the bearing bush moving device and the functional area device, and the bearing bush moving device and the functional area device are moved through the displacement adjustment device 3; the functional area device is installed with multiple processing units in the circumferential direction, and the bearing bush moving device r...

Embodiment 2

[0097] Embodiment 2 is a preferred example of embodiment 1

[0098] Example 2

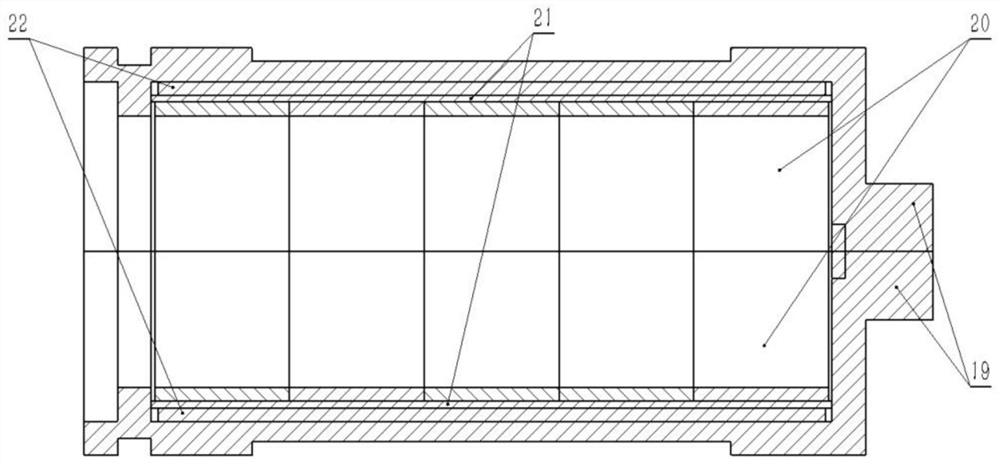

[0099] An integrated bearing bush spraying process equipment in an embodiment provided by the present invention includes a computer 1, a track 2, a displacement adjustment device 3, a bearing bush control frame 45, a bearing bush displacement mechanism 5, a bearing bush rotation mechanism 6, a bearing bush Set 7, degreasing device 8, cleaning device 9, drying device 10, sand blasting device 11, roughness detection device 12, phosphating device 13, vitrification device 14, spraying device 15, material supply and replacement device 16, functional area Auxiliary device 17 and functional area stand 18, wherein the bearing bush 7 mainly includes the bearing bush shell 19, the bearing bush 20, the bearing bush fixing device 21, the bearing bush adaptation displacement device 22 and the temperature sensor 23, the degreasing device 8 mainly includes the bearing bush 7, Ultrasonic generator 24, degreasing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com