A kind of alkaline corrosion auxiliary agent for cleaning polycrystalline silicon and its application

A technology of polysilicon and alkali etching, applied in the direction of surface etching composition, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of product yield decline, harmful nitrogen content, low yield, etc. Poor corrosion rate, reduced chemical cost, and improved product yield

Active Publication Date: 2022-05-31

CHANGZHOU SHICHUANG ENERGY CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the manufacturing process of this kind of battery, a layer of polysilicon (polysilicon) is coated on the back of the silicon wafer. In this step, a wrap-around phenomenon will occur, which will cause the front edge of the silicon wafer to be coated with polysilicon, which will affect the appearance and efficiency of the finished product. Degradation, in order to solve this phenomenon, the industry initially used high-end instruments to avoid the problem of coiling and plating. Now some factories have developed and used the following three chemical corrosion methods to solve the problem of coiling and plating:

[0003] 1) Using acid etching, hydrofluoric acid and nitric acid are used to remove the polysilicon on the front side, and the window of this method is narrow, which can easily lead to damage to the front PN junction and a significant drop in product yield; or directly double-sided Plating amorphous silicon, but the solution to the problem of front amorphous silicon affecting the appearance is still to use acid etching. This method still has a narrow window, which is easy to damage the front PN junction and cannot improve product yield, and acid etching also has air pollution. , nitrogen emissions and high chemical costs and other environmental issues;

[0004] 2) Only inorganic alkali potassium hydroxide or sodium hydroxide is used to remove the polysilicon on the front side. This method requires the BSG in the previous process to be thick enough to ensure that part of the BSG is retained when removing the polysilicon on the front side, but this The method window is narrow, the yield rate is not high in mass production, the efficiency and yield rate fluctuate greatly, and when making thick BSG, it will lead to low boron expansion capacity and low battery efficiency;

[0005] 3) Use TMAH (tetramethylhydrogen ammonia) to solve the problem of winding plating, but TMAH is a neurotoxin that has certain damage to the human body and the nitrogen content is too high. The dosage is large, and there is a nitrogen discharge problem.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

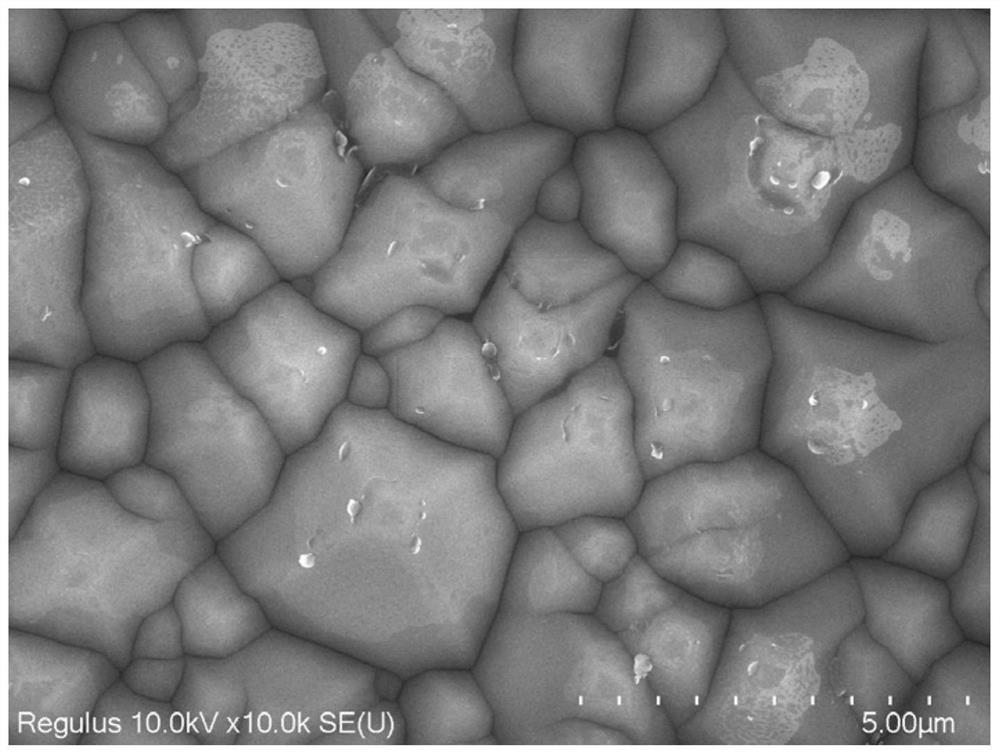

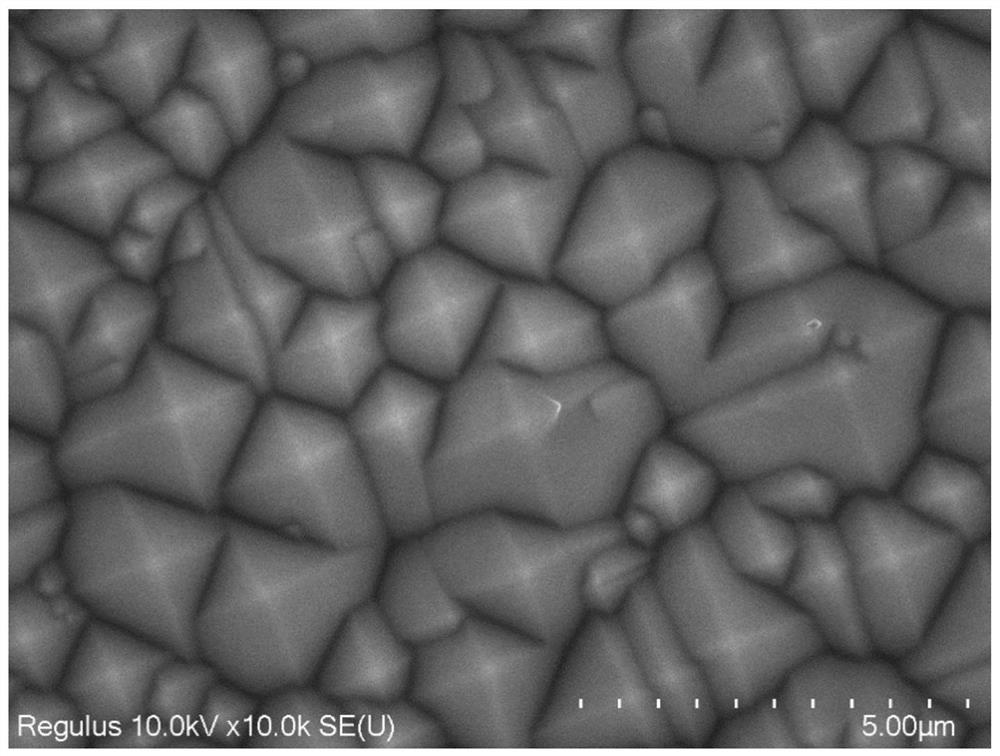

The invention discloses an alkali corrosion auxiliary agent for cleaning and plating polysilicon and its application. The mass percentage of each component in the alkali corrosion auxiliary agent is: 2%-5% polyether, 1%-2.5% anion Surfactant, 1%~2.5% dispersant, the balance is deionized water. The present invention adopts the alkali corrosion solution mixed with the alkali corrosion auxiliary agent to remove the polycrystalline silicon, replaces the acid corrosion or TMAH, improves the product yield and reduces the chemical cost, and does not have environmental protection problems such as nitrogen discharge, and has no harm to the human body; The corrosion auxiliary agent has selective adsorption and corrosion inhibition, and can corrode and remove the edge-wrapped polysilicon under the condition of protecting the pyramid structure from being damaged; the invention has a wide process window and stable efficiency, and can be applied to various equipment, such as slot machine, Chain machines can be used, which is convenient for the production line to use existing machines to achieve mass production.

Description

A kind of alkali corrosion auxiliary agent for cleaning and wrapping polysilicon and its application technical field [0001] The present invention relates to the field of photovoltaics, in particular to a kind of alkaline corrosion auxiliary agent for cleaning and wrapping polysilicon and application thereof. Background technique [0002] TOPCon (Tunnel Oxide Passivated Contact) is a high-efficiency crystalline silicon solar cell technology, The technology is to prepare an ultra-thin (about 1-2nm) tunneling oxide layer on the back of the battery, and then deposit a 20nm-thick phosphorus-doped layer The hetero-amorphous silicon layer is annealed at high temperature to form doped polysilicon, and the two together form a passivation contact structure. due to oxidation The layer is very thin, the thin layer of silicon is doped, the majority carrier can penetrate the two passivation layers, while the minority carrier is blocked, if redeposited on it Metals can then get pass...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K13/02H01L31/18

CPCC09K13/02H01L31/186H01L31/1804Y02P70/50

Inventor 邓雨微裴银强陈培良

Owner CHANGZHOU SHICHUANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com