Polyurethane with increased modulus after water absorption as well as preparation method and application of polyurethane

A polyurethane and post-molding technology, applied in the field of medical materials, can solve the problems of modulus and strength decrease, modulus increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of polyurethane material that absorbs water and causes hardening, its preparation method comprises the following steps:

[0042] 1) Dissolve Ymer N-120 (trimethylpropane polyethylene glycol monomethyl ether) with a number average molecular weight of 1000 in chloroform, wash with deionized water to remove residual water-soluble alkaline impurities in the raw material, and after phase separation, The chloroform phase was collected and dried by a rotary evaporator;

[0043] 2) Prepolymerization reaction: depressurize the YmerN-120 in step (1) in a three-neck round bottle and dry it in vacuum at 90-100°C for 2h, then add HMDI and organic bismuth catalyst in turn, and mechanically stir at 70°C for 1h;

[0044] 3) Chain extension reaction: add BDO (1,4-butanediol) to the result of step (2), stir for about 1 min, pour it into a polytetrafluoroethylene mold, and mature it at 100°C for 6 hours to make the reaction Carried out completely, polyurethane is obtained.

[004...

experiment example 1

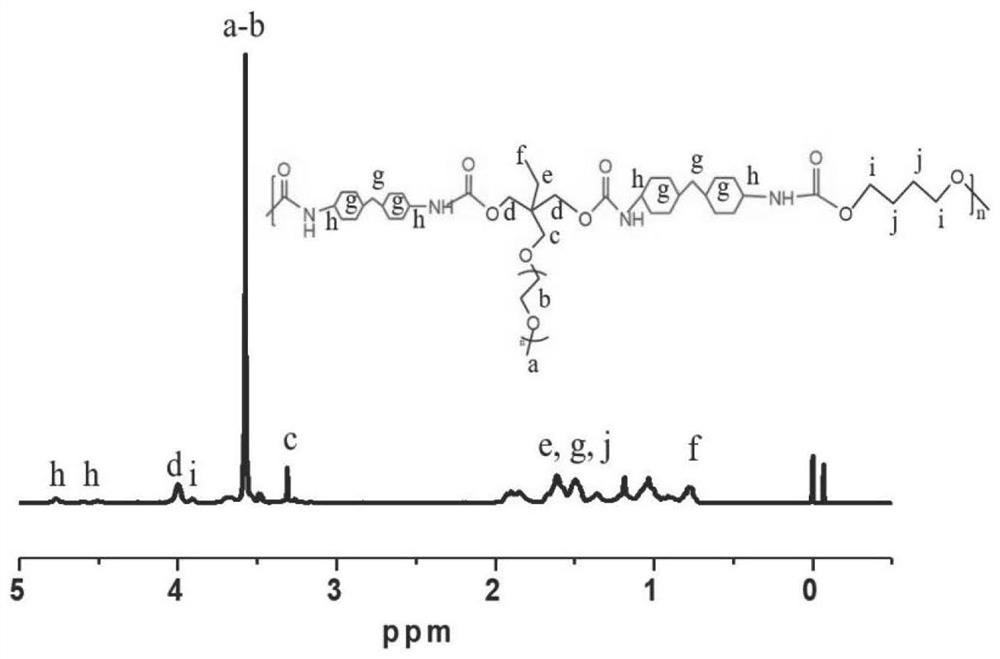

[0050] Characterization test is carried out to embodiment 1 gained SPPU series polyurethane, relevant characterization experiment method and data analysis are as follows:

[0051] 1) Gel Permeation Chromatography (GPC)

[0052] Weigh a certain amount of polyurethane sample and dissolve it in GPC mobile phase (LiBr / DMF) to make a polyurethane solution with a concentration of about 5 mg / mL, filter it with a 0.22 μm filter head to remove a small amount of impurities in the polyurethane solution, and then inject it into In the instrument, the test is performed, the mobile phase flow rate is set to 1mL / min, the instrument temperature is 40°C, and monodisperse polymethyl methacrylate (PMMA) is used as a standard sample to calculate the molecular weight of the sample.

[0053] The test results show (see Table 2) that the molecular weights and distributions of all samples are within a reasonable range and relatively close.

[0054] Table 2 Molecular weight and distribution of SPPU se...

Embodiment 2

[0069] A polyurethane material hardened by water absorption, its preparation method refers to Example 1, the difference is that half of the chain extender BDO in the SPPU is replaced by a polycaprolactone oligomer diol with an average degree of polymerization of 2, synthesized Polyurethane is called DSPPU (synthetic route sees Figure 5 ), the polyurethane can be degraded by hydrolysis of ester bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com