Two-dimensional carbon-metal configuration composite material and preparation method and application thereof

A two-dimensional carbon, composite material technology, applied in chemical instruments and methods, heat exchange materials, electrical components, etc., can solve the problem of difficult to meet the matching requirements of high thermal conductivity and low thermal expansion coefficient of thermal management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the preparation method of the present invention, aluminum foil, surface-modified copper foil, graphite paper, and graphene film are laminated and rolled, or graphite flakes and graphene nanosheets after ultrasonication are laminated with aluminum foil and surface-modified copper foil Compositing, constructing a coaxial helical laminated structure, and finally obtaining a two-dimensional carbon-metal structured composite material with high thermal conductivity and low thermal expansion coefficient matching through hot isostatic pressing sintering and hot extrusion.

[0044]

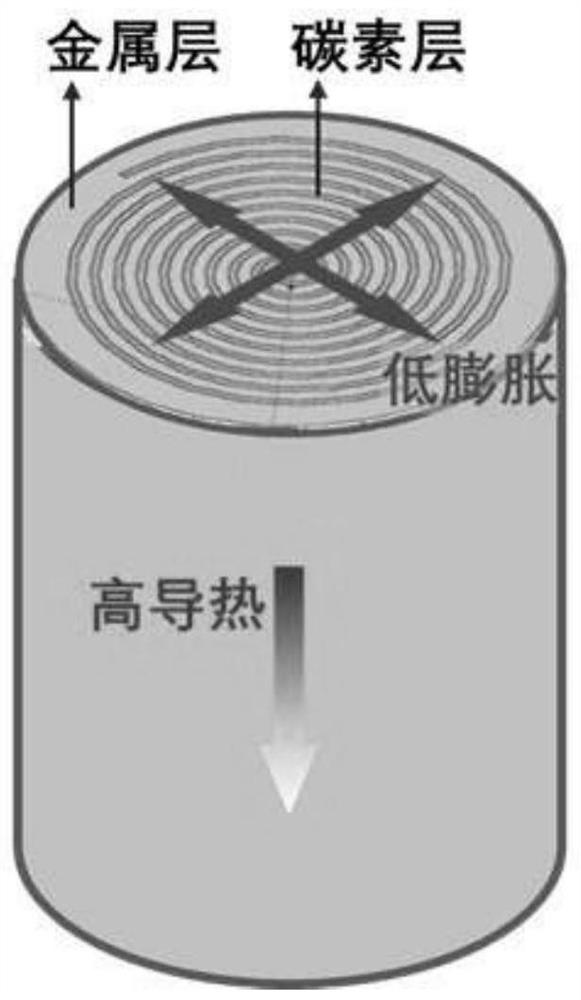

[0045] Such as figure 1 As shown, the two-dimensional carbon-metal configuration composite material of the present invention is obtained by the coaxial configuration of the metal foil with a volume fraction of 20-90% and the carbon material with a volume fraction of 10-80%; wherein, the metal foil is selected from From aluminum foil or surface-modified copper foil; the carbon material is select...

Embodiment 1

[0072] The preparation method of the two-dimensional graphite paper-copper composite material of the present embodiment comprises the following steps:

[0073] (1) Annealing a copper foil with a thickness of 25 μm in a hydrogen-argon mixed atmosphere to remove surface oxides to obtain an annealed copper foil.

[0074] (2), use chemical vapor deposition (CVD) to grow graphene in situ on the surface of the annealed copper foil, then place the graphene-modified copper foil and graphite paper with a purity of 99.9% and a thickness of 15 μm, and roll it It is 6 cm in diameter and a single-core coaxial cylinder blank with a height of 10 cm.

[0075] (3) The single-core coaxial cylinder billet is then subjected to hot isostatic pressing sintering under the protection of an argon atmosphere. The temperature in the furnace rises to 900°C in 2 hours, and the pressure is increased to 130MPa while the temperature is rising, followed by heat preservation and pressure holding for 2 hours. ...

Embodiment 2

[0078] The preparation method of the two-dimensional graphite paper-aluminum composite material of the present embodiment comprises the following steps:

[0079] (1) Annealing an aluminum foil with a thickness of 25 μm in an argon atmosphere to remove surface oxides to obtain an annealed aluminum foil.

[0080] (2), the annealed aluminum foil and graphite paper with a purity of 99.9% and a thickness of 25 μm are laminated and rolled into a single-core coaxial cylinder blank with a diameter of 6 cm and a height of 10 cm.

[0081] (3) The single-core coaxial cylinder billet is then subjected to hot isostatic pressing sintering under the protection of an argon atmosphere. The temperature in the furnace rises to 500°C in 2 hours, and the pressure is increased to 130MPa while the temperature is rising, followed by heat preservation and pressure holding for 2 hours. Cooling was started to obtain a graphite paper-aluminum composite body with a single-core coaxial configuration and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com