Cotton fabric surface TiO2-BC/PDMS hydrophobic coating and preparation method thereof

A technology of hydrophobic coating and cotton fabric, applied in the field of cotton fabric, can solve the problems of low secondary utilization rate, high cost, inability to optimize superhydrophobicity and photocatalytic performance at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

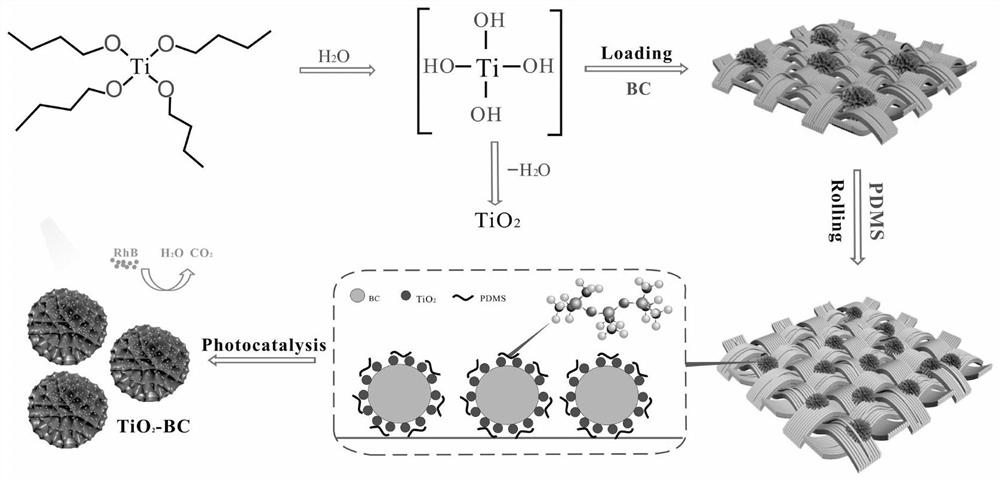

[0034] TiO in this example 2 -The preparation method of BC / PDMS hydrophobic coating comprises the following steps (as image 3 shown):

[0035] S1: Mix 10ml of absolute ethanol and 10ml of tetrabutyl titanate with magnetic force for 30 minutes, then add dilute hydrochloric acid drop by drop until the pH value is less than 3, and then add 2ml of double distilled water drop by drop after uniform stirring.

[0036] When tetrabutyl titanate is hydrolyzed, the solution system gradually becomes slightly viscous. This is because the hydrolysis reaction speed is faster in the hydrolysis process of TBTO, and the polycondensation reaction speed is also accelerated, and the polymerization degree and crosslinking degree of the hydrolyzed polycondensate increase. Large, when the equilibrium is reached, the solution will form a polymer with a network space structure, and with the completion of the reaction, the polymer will gradually form a transparent colloid.

[0037] S2: Add 0.5g of ba...

Embodiment 2

[0067] TiO in this example 2 -The preparation method of BC / PDMS hydrophobic coating comprises the following steps:

[0068] S1: After mixing 10ml of absolute ethanol and 10ml of tetrabutyl titanate with magnetic force for 25 minutes, add dilute hydrochloric acid drop by drop until the pH value is less than 3, and then add 1.75ml of double distilled water drop by drop after uniform stirring;

[0069] S2: Add 0.48g of bamboo charcoal powder while stirring, and let it stand to get TiO 2 -BC-sol;

[0070] S3: TiO 2 After drying in the oven, the BC sol is heated up to 495°C every 29 minutes from room temperature in a muffle furnace, kept for 118 minutes and then continuously raised to 600°C, cooled naturally, and ground to produce a slightly shiny TiO 2 - BC composite particles;

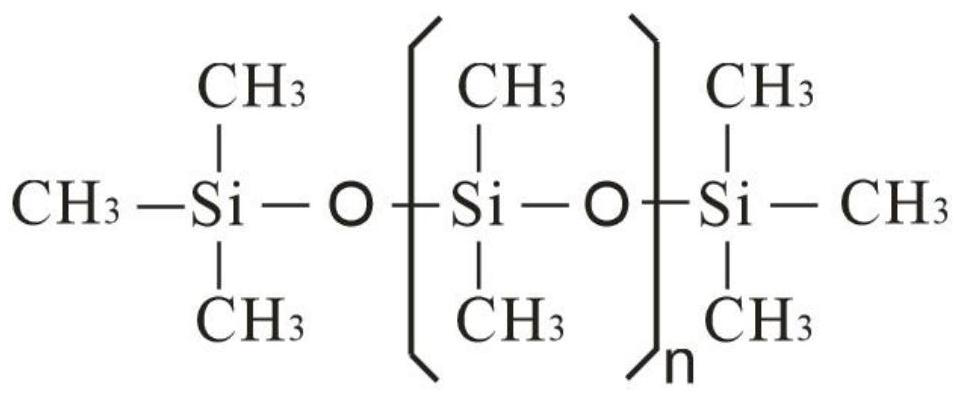

[0071] S4: Take the prepared TiO 2 -BC composite material 0.5g, isopropanol 20ml, 2g vinyltrimethoxysiloxane (VTMO), hydrophobic polymer PDMS, in the form of simple blending, to TiO 2 -BC particles ...

Embodiment 3

[0073] TiO in this example 2 -The preparation method of BC / PDMS hydrophobic coating comprises the following steps:

[0074] S1: After mixing 10ml of absolute ethanol and 10ml of tetrabutyl titanate with magnetic force for 35 minutes, add dilute hydrochloric acid drop by drop until the pH value is less than 3, and then add 2.25ml of double distilled water drop by drop after uniform stirring;

[0075] S2: Add 0.52g of bamboo charcoal powder while stirring, and let it stand to get TiO 2 -BC-sol;

[0076] S3: TiO 2 -BC sol was dried in an oven and then heated up to 505°C in stages every 31 minutes from room temperature in a muffle furnace, kept for 122 minutes and then continued to heat up to 800°C, cooled naturally, and ground to produce slightly shiny TiO 2 - BC composite particles;

[0077] S4: Take the prepared TiO 2 -BC composite material 0.5g, isopropanol 20ml, 2g vinyltrimethoxysiloxane (VTMO), hydrophobic polymer PDMS, in the form of simple blending, to TiO 2 -BC par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com