Preparation method of nano barium titanate/ferroferric oxide hybrid material with high wave-absorbing performance

A technology of triiron tetroxide and hybrid materials, applied in the directions of iron oxide/iron hydroxide, chemical instruments and methods, titanate, etc., can solve the problem of narrow absorption frequency band, unsatisfactory wave absorption performance of pure barium titanate, cost Advanced problems, to achieve the effect of reducing direct reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Weigh 4.0g NaOH into a beaker, then add 10ml of water first, and then add 10ml of absolute ethanol after the NaOH is dissolved in the water. Then 2.3319g nano BaTiO 3 Add absolute ethanol to the powder and grind it into a slurry, pour it into the above beaker, and then add 100ml of absolute ethanol. Put the above beaker into a magnetic stirrer with the temperature set at 70 °C. 1.9881g FeCl 2 4H 2 O and 2.7030 g FeCl 3 ·6H 2 O was dissolved in 60ml of absolute ethanol, and the solution was added to the burette, and added dropwise to the above emulsion through the burette, stirring continuously. After all the solutions are added, let stand, separate layers, pour off the supernatant, add water, after standing still, pour off the supernatant again, and repeat this step three times (stand and separate at room temperature, no aging is required). After five times of suction filtration, it was placed in a drying oven at a temperature of 60° C. for 24 hours to obtain a br...

example 1

[0094] The magnetic stirrer in the example 1 only turns on the heating switch, and the rotating speed is adjusted to 0rmp, and an electric stirrer is used above.

Embodiment 2

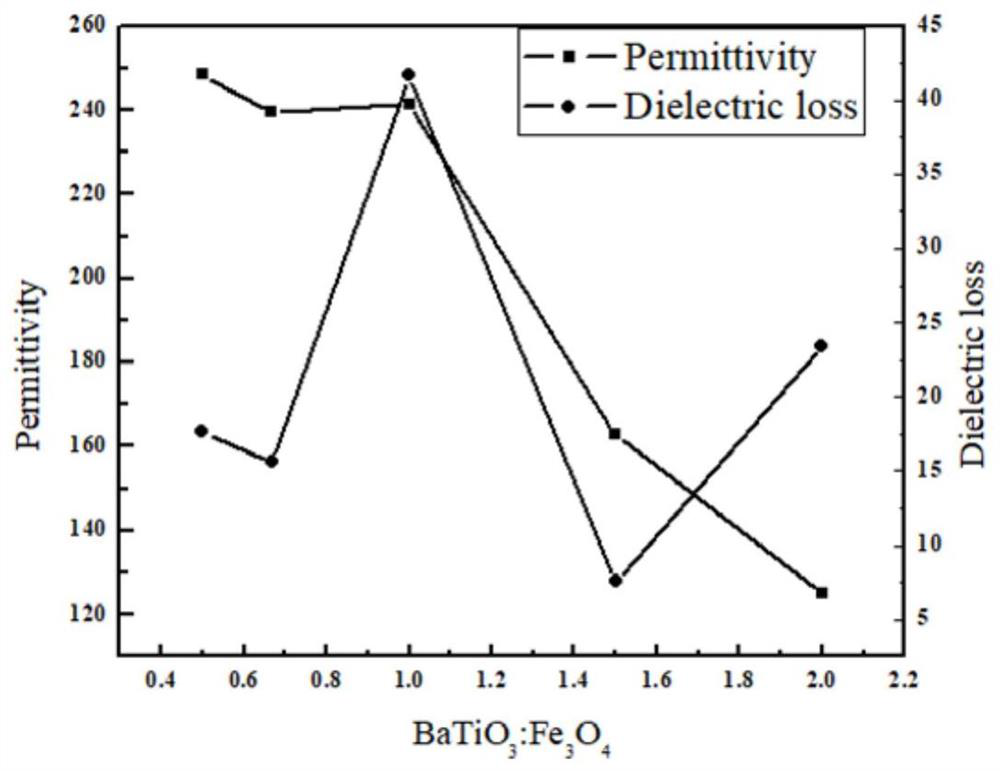

[0096] Nano BaTiO used 3 The powder is the same as in Example 1, and the nano-BaTiO obtained by the solution direct synthesis method is earlier 3 Powder. Weigh 4.0g NaOH into a beaker, then add 10ml of water first, and then add 10ml of absolute ethanol after the NaOH is dissolved in the water. Then 4.6638g nanometer BaTiO 3 Add absolute ethanol to the powder and grind it into a slurry, pour it into the above beaker, and then add 100ml of absolute ethanol. Put the above beaker into a magnetic stirrer with the temperature set at 70 °C. 1.9981g FeCl 2 4H 2 O and 2.7030 g FeCl 3 ·6H 2 O was dissolved in 60ml of absolute ethanol, and the solution was added to the burette, and added dropwise to the above emulsion through the burette, stirring continuously. After all the solutions are added, let stand, separate layers, pour off the supernatant, add water, after standing still, pour off the supernatant again, and repeat this step three times (stand and separate at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic loss | aaaaa | aaaaa |

| magnetic loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com