Block polyether for early-strength shrinkage-resistant polycarboxylate water reducing agent and preparation method of block polyether

A technology of block polyether and polycarboxylic acid, which is applied in the field of block polyether and its preparation, can solve the problems of low concrete slump and fluidity, concrete bleeding, poor adaptability, etc., and achieve improved affinity Water-lipophilicity, promotion of cement hydration, and the effect of reducing the sensitivity of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

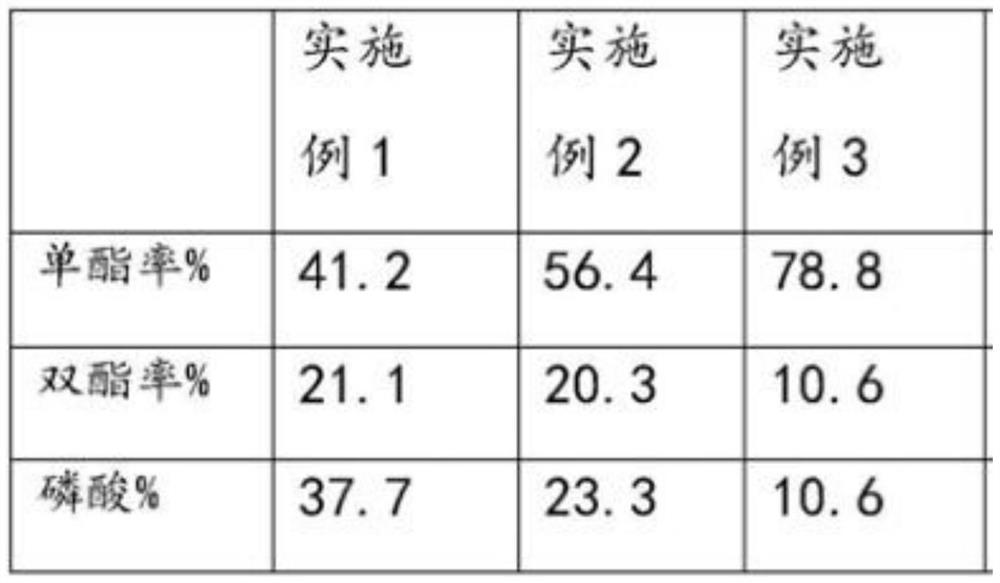

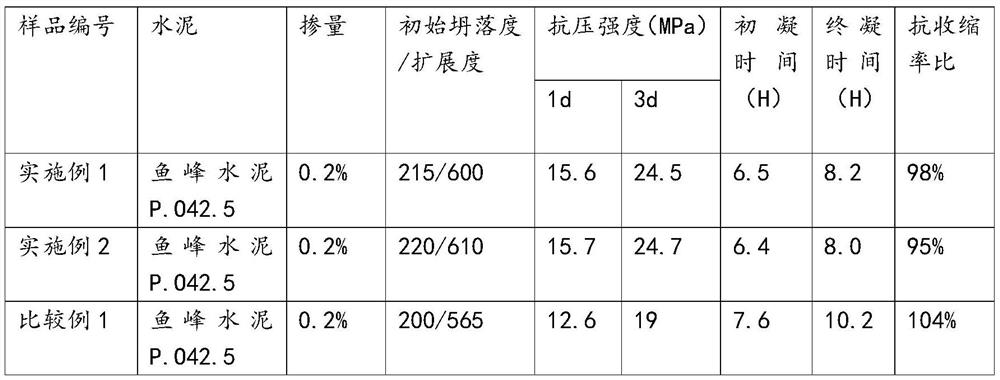

[0036] Example 1: A block polyether for early-strength polycarboxylate water reducer, obtained by reacting the following components in terms of weight percentage: prenol polyoxyethylene ether with a molecular weight of 700 is 346g , the basic catalyst is 0.3g, the basic catalyst is selected powdery sodium methylate, the ethylene oxide is 948.3g, the propylene oxide is 286.7g, the weak acid neutralizer is 0.9g, and the weak acid is selected acetic acid.

[0037] The molecular weight is 350g of isopentenol polyoxyethylene ether of 700,

[0038] raw material:

[0039] a. Isopentenol polyoxyethylene ether-2400 (the number indicates the weight average molecular weight, the same below);

[0040] B, phosphorus pentoxide (analytical pure);

[0041] c, sulfamic acid;

[0042] d, sodium hydroxide (using mass fraction is 40% sodium hydroxide aqueous solution).

[0043] Wherein the molar ratio of raw materials a and b is 2:1;

[0044] Raw material c is 1.0% of the total mass of a and...

Embodiment 2

[0049] Example 2: A block polyether for early-strength polycarboxylate water reducer, obtained by reacting the following components in terms of weight percentage: 350 g of isopentenol polyoxyethylene ether with a molecular weight of 1800 , the basic catalyst is 0.3g, the basic catalyst is selected powdery sodium methylate, ethylene oxide is 503.6g, propylene oxide is 111.5g, the weak acid neutralizer is 0.9g, and the weak acid is selected acetic acid for use.

[0050] Example 2, the molecular weight is 350g of isopentenol polyoxyethylene ether of 1800

[0051] raw material:

[0052] a. Isopentenol polyoxyethylene ether-2000;

[0053] B, phosphorus pentoxide (analytical pure);

[0054] c. 98% concentrated sulfuric acid;

[0055] d, sodium hydroxide (using mass fraction is 40% sodium hydroxide aqueous solution).

[0056] Wherein the molar ratio of raw materials a and b is 2:1;

[0057] Raw material c is 0.5% of the total mass of a and b;

[0058] Raw material d is 1.0% of ...

Embodiment 3

[0060] Embodiment 3, raw material:

[0061] a. Isopentenol polyoxyethylene ether-1800;

[0062] B, phosphorus pentoxide (analytical pure);

[0063] d, sodium hydroxide (using mass fraction is 40% sodium hydroxide aqueous solution).

[0064] Wherein the molar ratio of raw materials a and b is 1.9:1;

[0065] Raw material d is 0.125% of the total mass of a and b.

[0066] The four-neck flask is equipped with a thermometer, a stirring and reflux device, and is protected by nitrogen. Put the TPEG-1800 monomer into a four-necked bottle, heat it to 50°C in a water bath to melt, and stir for 5 minutes. Add phosphorus pentoxide in batches at 50°C, each time not exceeding 10% of the total amount of phosphorus pentoxide, with an interval of 10 minutes each time. Control the temperature not to exceed 50°C. After adding phosphorus pentoxide, the temperature was raised to 70°C for 4 hours. Lower the temperature to 50°C for neutralization to obtain the phosphorylated monomer of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com