Graphite-phase C3N4 nanosheet two-dimensional film for oil-water separation and preparation method thereof

A C3N4, oil-water separation technology, applied in the field of membrane separation, can solve problems such as water pollution, achieve the effect of large separation flux, not easy to collapse, good thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

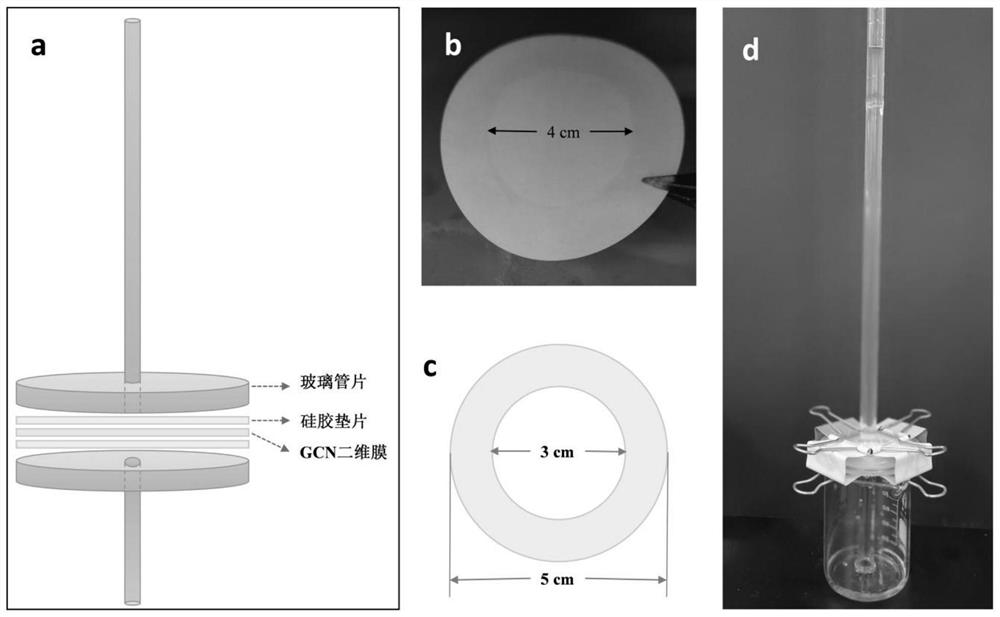

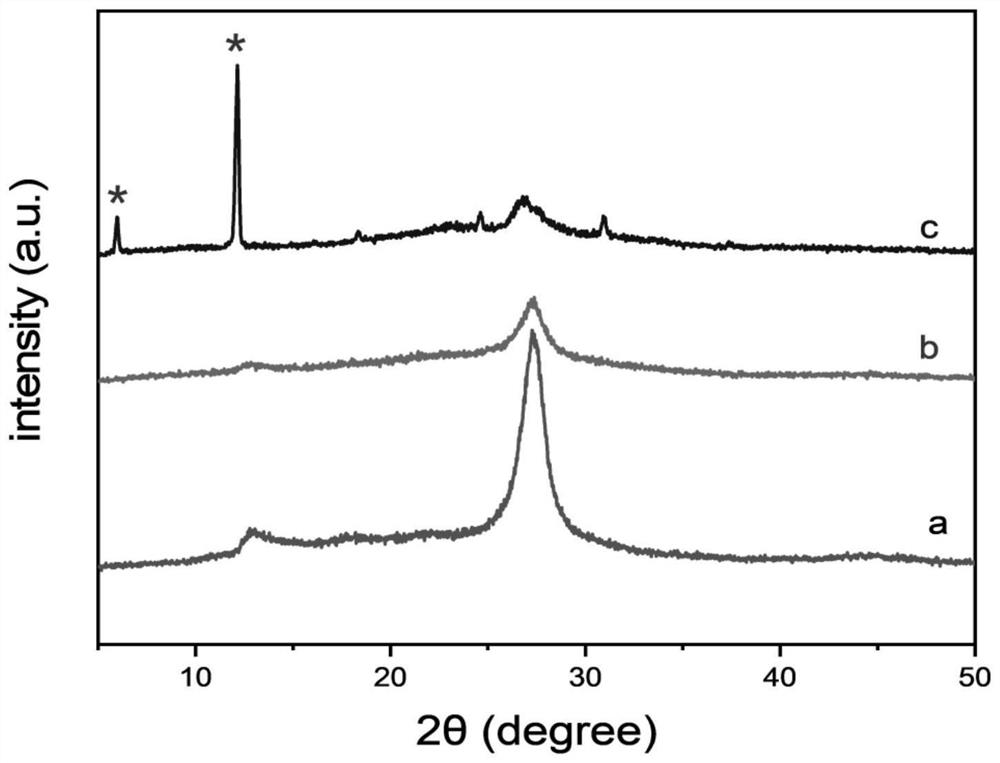

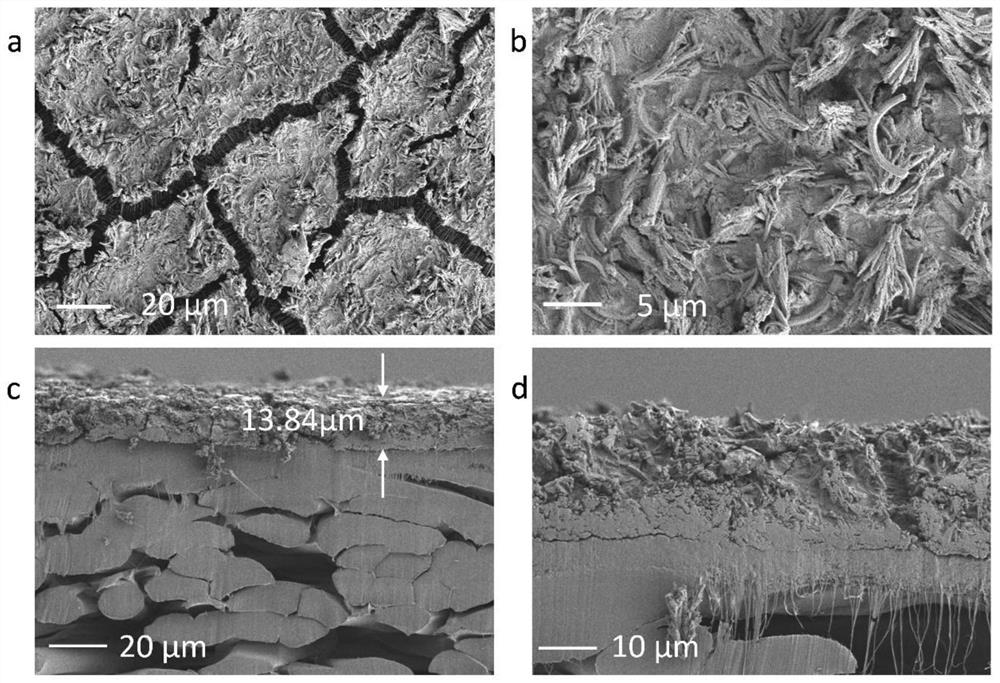

[0041] (1) Preparation of pristine GCN powder. Take 5g of melamine powder and put it on a loose cover (the matching ceramic crucible cover is directly covered on the crucible without airtightness, which will not affect the gas exchange inside and outside the crucible during the heating process, and only prevents impurities from falling into the crucible sample.) In a crucible, heated to 600°C at a rate of 1°C / min in an air atmosphere muffle furnace for thermal condensation, kept at a temperature of 2 hours, and then cooled to room temperature at a rate of 3°C / min to obtain light yellow GCN powder, Grind the powder thoroughly for later use.

[0042] (2) Preparation of GCN-sulfuric acid (SA) composites. Weigh 700mg of GCN powder, add 10mL of concentrated sulfuric acid (98wt%) to GCN, stir and heat in an oil bath at 100°C for 12h, and let it stand until it is naturally cooled to room temperature to form a transparent and uniform bright yellow GCN-SA solution . Accurately pipet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com