Preparation method and application of high-efficiency halogen-free flame retardant for polypropylene

A technology of flame retardant and polypropylene, which is applied in the field of flame retardants, can solve the problems of aluminum hypophosphite flame retardants being flammable, and achieve the effects of good matrix compatibility, increased flame retardant effect, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

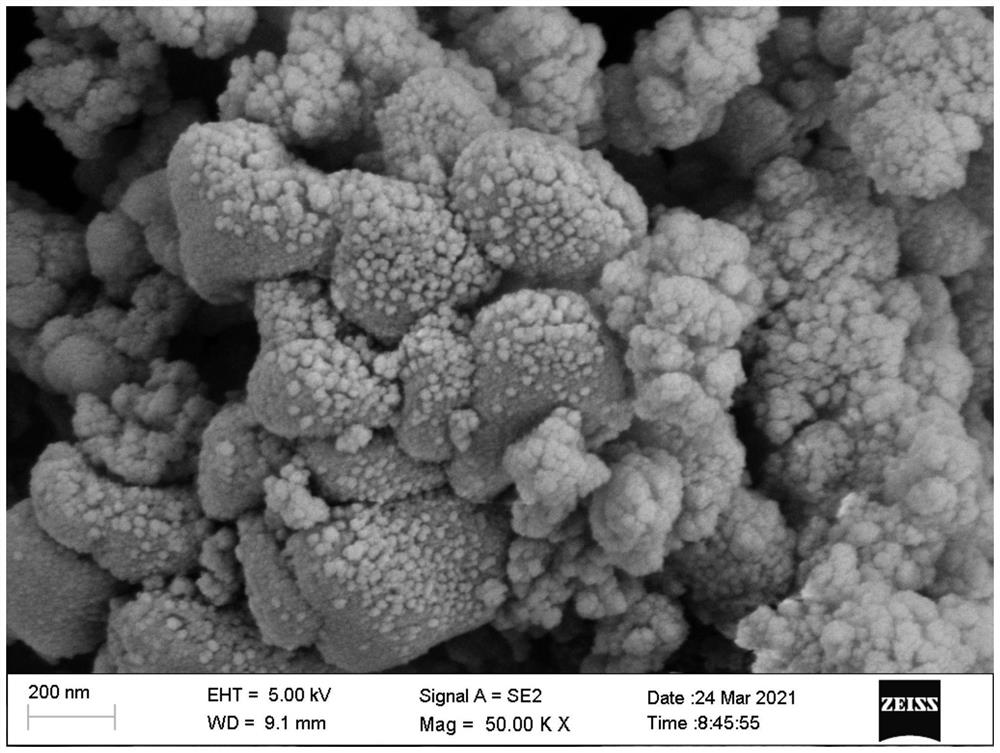

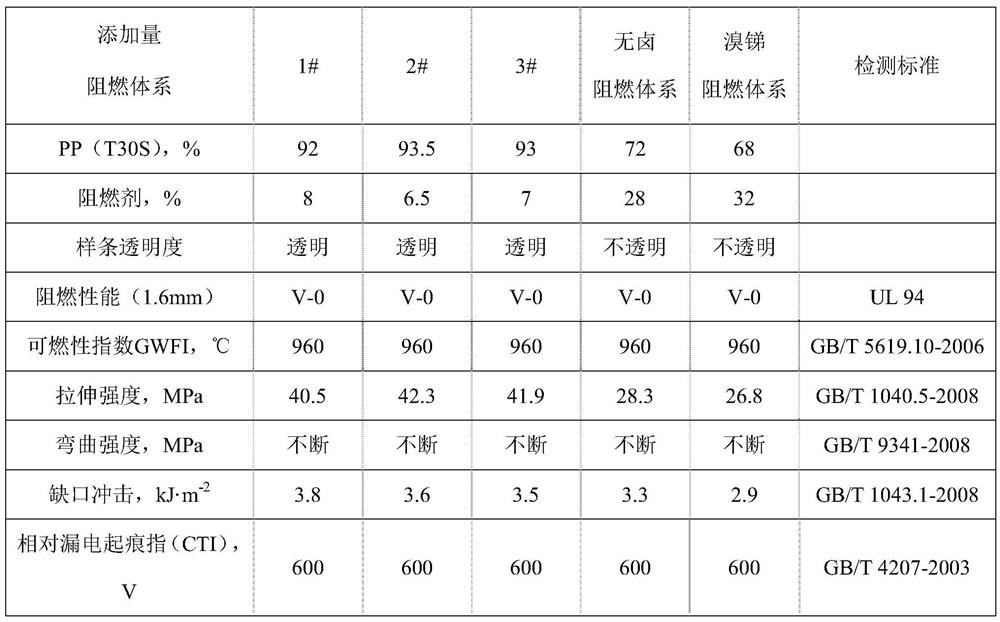

[0024] (1) 135 parts of sodium hypophosphite and 146 parts of aluminum sulfate were added to the reaction vessel that had been added to the water respectively, and the heating and stirring were turned on to be warmed up to 105 ° C, and a constant temperature was maintained until it was completely dissolved; then the sodium hypophosphite solution was slowly added In the aluminum sulfate solution, the reaction was stirred at 105 °C for 6 h to obtain aluminum hypophosphite slurry;

[0025] (2) Turn off the heating to cool down, add magnesium hydroxide water dispersion system when the aluminum hypophosphite slurry is cooled to 70 ℃ (add 8 parts of magnesium hydroxide to water and stir and disperse), and at a constant temperature of 70 ℃, magnesium hydroxide and hypophosphorous acid are added. The aluminum slurry is neutralized and washed with suction after 4 hours of reaction to obtain an aluminum hypophosphite product co-coated with magnesium hypophosphite and aluminum magnesium h...

Embodiment 2

[0028] (1) 142 parts of sodium hypophosphite and 154 parts of aluminum sulfate were added to the reaction vessel that had been added to the water respectively, and the heating and stirring were turned on to be warmed up to 115 ° C, and a constant temperature was maintained to be completely dissolved; then the sodium hypophosphite solution was slowly added In the aluminum sulfate solution, the reaction was stirred at 110 °C for 4 h to obtain aluminum hypophosphite slurry;

[0029] (2) Turn off the heating to cool down, add magnesium hydroxide water dispersion system (9.5 parts of magnesium hydroxide is added to water and stir and disperse) when the aluminum hypophosphite slurry is cooled to 80°C, and magnesium hydroxide and hypophosphorous acid are added at a constant temperature of 75°C. The aluminum slurry is neutralized and washed with suction after 3 hours of reaction to obtain an aluminum hypophosphite product co-coated with magnesium hypophosphite and aluminum magnesium hy...

Embodiment 3

[0032] (1) 126 parts of sodium hypophosphite and 138 parts of aluminum sulfate were added into the reaction vessel that had been added to water respectively, and the heating and stirring were turned on to be warmed up to 95 ℃, and the constant temperature was kept to be completely dissolved; then the sodium hypophosphite solution was slowly added In the aluminum sulfate solution, the reaction was stirred at 95 °C for 5 h to obtain aluminum hypophosphite slurry;

[0033] (2) turn off the heating to cool down, add magnesium hydroxide water dispersion system when the aluminum hypophosphite slurry is cooled to 70 ℃ (add 6 parts of magnesium hydroxide to the water and stir and disperse), and at a constant temperature of 80 ℃, magnesium hydroxide and hypophosphorous acid are added. The aluminum slurry is neutralized, and after 2.5 hours of reaction, suction filtration and washing are performed to obtain an aluminum hypophosphite product co-coated with magnesium hypophosphite and alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com