Small-specification horizontal machine PCD enamelling mold

A technology of small size and mold, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of small wear ratio of tungsten steel mold core, fast wear consumption, low production efficiency of workers, etc., to avoid fast wear and consumption, Reduced surface roughness and improved die breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is a kind of sintering raw material, and the preparation process of sintering raw material is as follows:

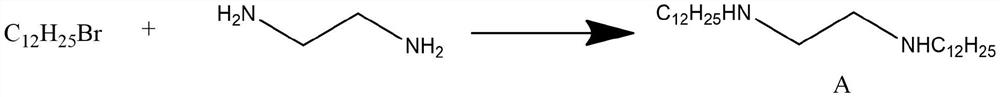

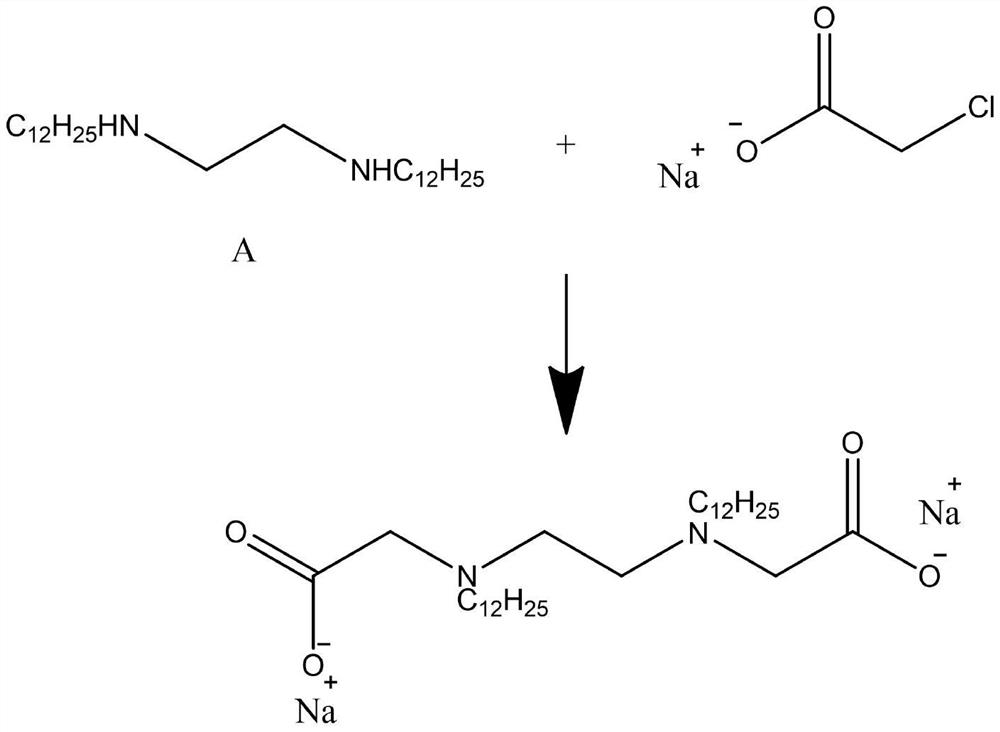

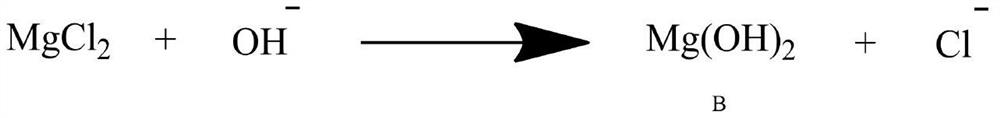

[0036]S1: Add ethylenediamine and absolute ethanol to a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, stir for 20min at a temperature of 55°C and a stirring rate of 200r / min, and then add bromine dropwise The ethanol solution of dodecane, control the dropping rate at 1mL / min, continue to stir and react for 10h after the dropwise addition is completed, after the reaction is completed, cool the reaction product to room temperature, vacuum filter, and wash the filter cake 3 times with absolute ethanol , then put the filter cake in a vacuum drying oven, and dry it to a constant weight at a temperature of 50°C to obtain an intermediate product A; control the ratio of ethylenediamine to absolute ethanol to be 1g: 10mL, bromide deca The ethanol solution of dioxane is a solution formed by bromododecane and absolute eth...

Embodiment 2

[0041] This embodiment is a kind of sintering raw material, and the preparation process of sintering raw material is as follows:

[0042] S1: Add ethylenediamine and absolute ethanol to a three-necked flask equipped with a stirrer and a constant pressure dropping funnel, stir for 30min at a temperature of 65°C and a stirring rate of 400r / min, and then add bromine dropwise The ethanol solution of dodecane, control the dropping rate at 2mL / min, continue to stir and react for 12h after the dropwise addition is completed, after the reaction is completed, cool the reaction product to room temperature, vacuum filter, and wash the filter cake with absolute ethanol for 5 times , and then put the filter cake in a vacuum drying oven, and dry it to a constant weight at a temperature of 80°C to obtain an intermediate product A; control the ratio of ethylenediamine to absolute ethanol to be 1g: 20mL, bromide deca The ethanol solution of dioxane is a solution formed by bromododecane and abs...

Embodiment 3

[0047] This embodiment is a small-sized horizontal machine PCD painting mold, which is prepared by the following steps:

[0048] Step 1: Cut the PCD composite sheet into the required shape by laser, and then undergo ultrasonic shaping and polishing to the required hole shape and size to obtain the mold core;

[0049] Step 2: Fix the mold base with a graphite mold sleeve, place the mold core in the mold, then add sintering raw materials between the mold base and the mold core, and then put it on a hot-press sintering machine for sintering, heat the mold core with powder metallurgy process Pressing and sintering is fixed to the center of the mold base to obtain the small-sized horizontal machine PCD painting mold;

[0050] Wherein, the preparation process of sintering raw materials is as follows:

[0051] A1: Weigh 70 parts of electrolytic copper, 5 parts of zinc, 5 parts of cobalt, 5 parts of molybdenum, 10 parts of nickel, 5 parts of chromium, 5 parts of tin and 5 parts of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com