Preparation method of high-adhesion superhydrophobic surface based on laser chemical composite process

A super-hydrophobic surface and high-adhesion technology, which is applied in the direction of surface coating liquid devices, special surfaces, pre-treated surfaces, etc., can solve the constraints on the industrialization of ultra-fast laser processing methods and the processing of ultra-fast laser processing methods Low efficiency, difficult laser maintenance and other problems, to achieve the effect of high reliability, lower production cost, high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the high-adhesion super-hydrophobic surface based on the laser chemical composite process according to the embodiment of the present invention includes the following steps:

[0025] Step 10) cleaning the substrate: cleaning the alloy substrate;

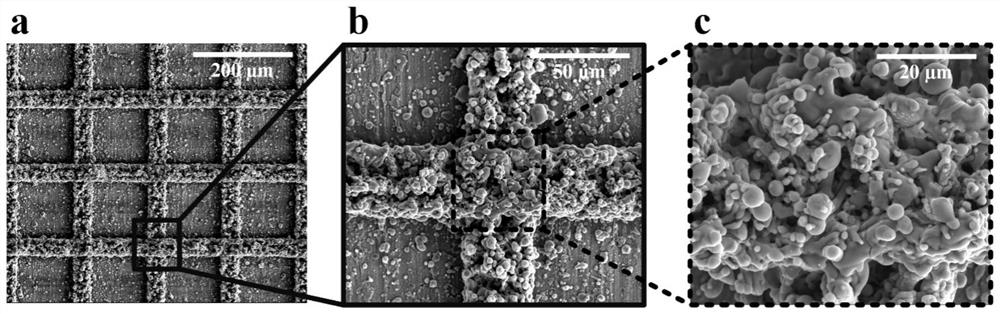

[0026] Step 20) Laser surface micro-texture: place the cleaned alloy substrate on the sample stage of the ultraviolet nanosecond laser processing system, use a laser beam to process the micro-nano structure on the surface of the alloy substrate, and then ultrasonically clean it in absolute ethanol for 10~ 15 minutes;

[0027] Step 30) Wetting with silane solution: the alloy substrate treated in step 20) is soaked in a mixed solution of 1H, 1H, 2H, 2H-tetrahydroperfluorooctyltrichlorosilane and ethanol, and then taken out and placed in nitrogen Blow dry in the stream, and finally put it in the oven to bake;

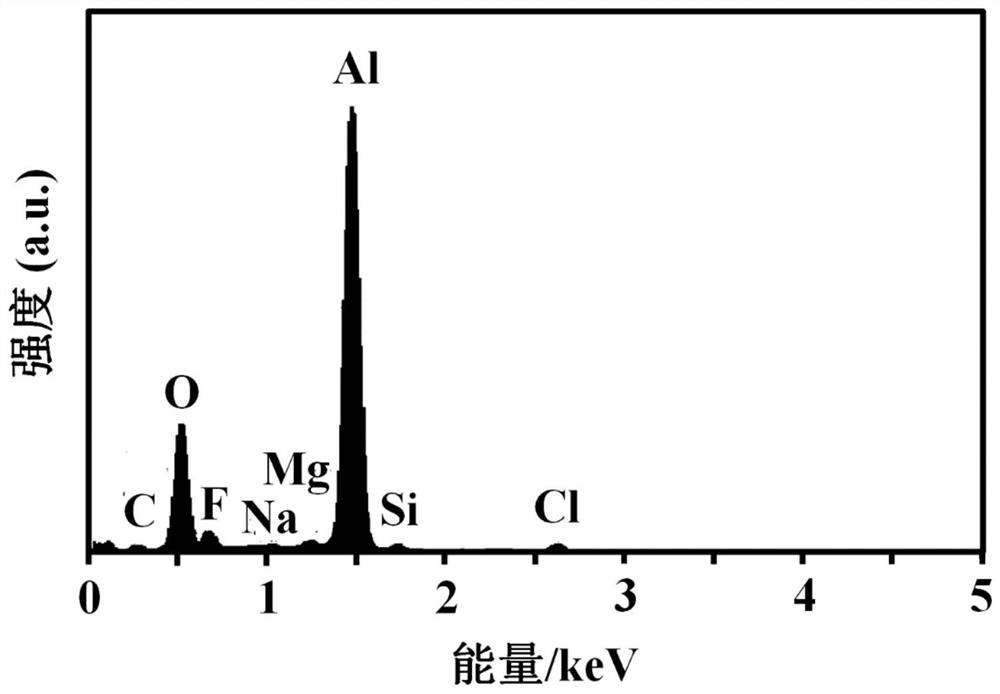

[0028] Step 40) Sodium chloride solution soaking: soak the alloy substrate treated in step 30...

Embodiment 1

[0040] Step 10) Cut the AA6061 aluminum alloy substrate into a size of 15mm×15mm, and then use acetone, anhydrous ethanol, and deionized water to ultrasonically clean the substrate for 10 minutes in order to remove contaminants on the substrate surface. It was then blown dry in a stream of nitrogen.

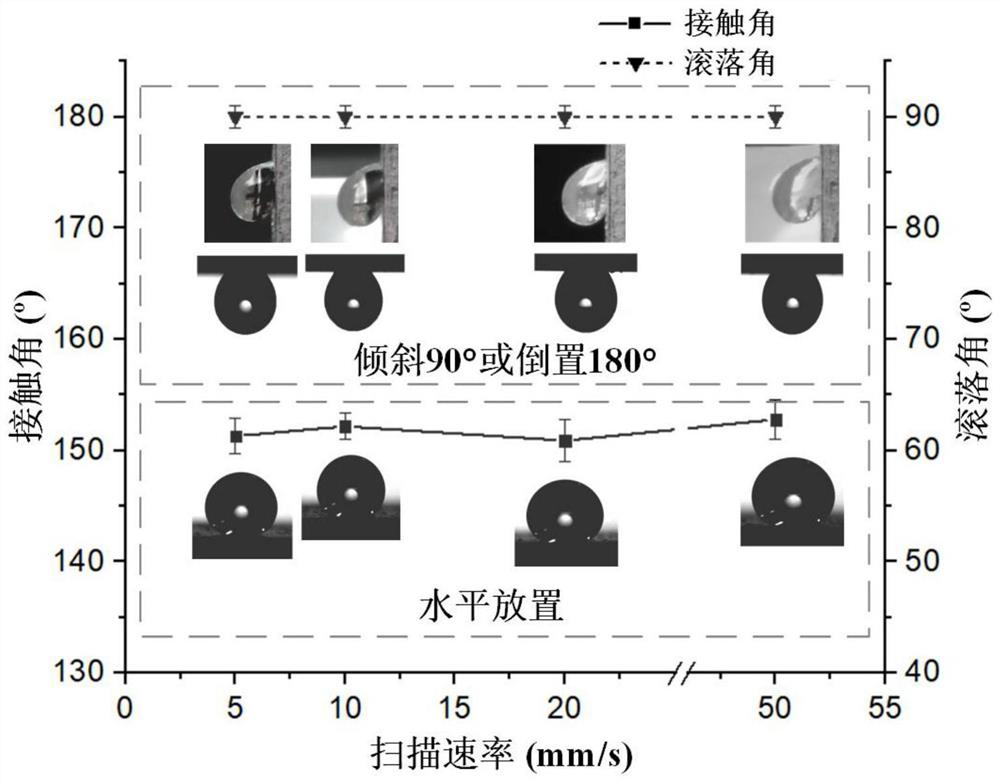

[0041] Step 20) Perform laser microtexturing on the surface, and the selected laser parameters are as follows: the pulse width is 20ns, the laser wavelength is 355nm, the pulse repetition frequency is 30kHz, the laser power is 15W, the pulse energy is 0.5mJ, and the laser power density is 5.0 GW / cm 2 , the effective spot diameter after focusing is about 25 μm, the laser scanning rate is 50 mm / s, and the laser beam scanning area is 12 mm×12 mm. The laser-prepared substrates were placed in absolute ethanol for ultrasonic cleaning for 10 minutes.

[0042] Step 30) Soak the substrate in a mixed solution of 1H, 1H, 2H, 2H-tetrahydroperfluorooctyltrichlorosilane with a volume fractio...

Embodiment 2

[0046] Step 10) Cut the AA6061 aluminum alloy substrate into a size of 16 mm×16 mm, and then use acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 12 minutes in sequence to remove contaminants on the surface of the substrate. It was then blown dry in a stream of nitrogen.

[0047] Step 20) Perform laser microtexturing on the surface, and the selected laser parameters are as follows: the pulse width is 20ns, the laser wavelength is 355nm, the pulse repetition frequency is 10kHz, the laser power is 1W, the pulse energy is 0.1mJ, and the laser power density is 1.0 GW / cm 2 , the effective spot diameter after focusing is about 26 μm, the laser scanning rate is 5 mm / s, and the laser beam scanning area is 12 mm × 12 mm. The laser-prepared substrates were placed in absolute ethanol for ultrasonic cleaning for 12 minutes.

[0048] Step 30) Soak the substrate in a mixed solution of 1H, 1H, 2H, 2H-tetrahydroperfluorooctyltrichlorosilane with a volume fraction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com