Preparation method and application of manganese-cobalt spinel coating

A spinel coating and manganese-cobalt technology, which is applied to the preparation field of manganese-cobalt spinel coating, can solve the problems of poor conductivity, low activity, increased internal resistance of batteries, etc., and achieves uniform and dense texture, simple preparation process, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to one aspect of the present invention, a kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0049] (a), providing manganese-cobalt mixed powder, then mixing the manganese-cobalt mixed powder with the solution to obtain a mixed slurry;

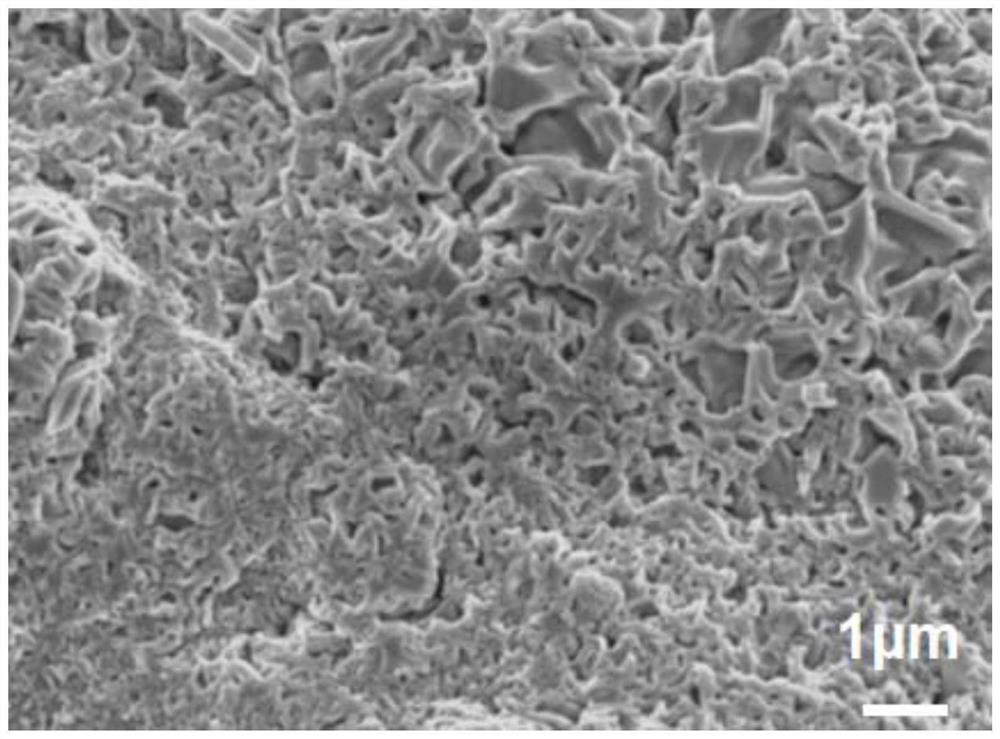

[0050] (b), the mixed slurry is coated on the surface of the ferritic stainless steel connecting body, dried, and an intermediate coating A is obtained on the surface of the ferritic stainless steel connecting body;

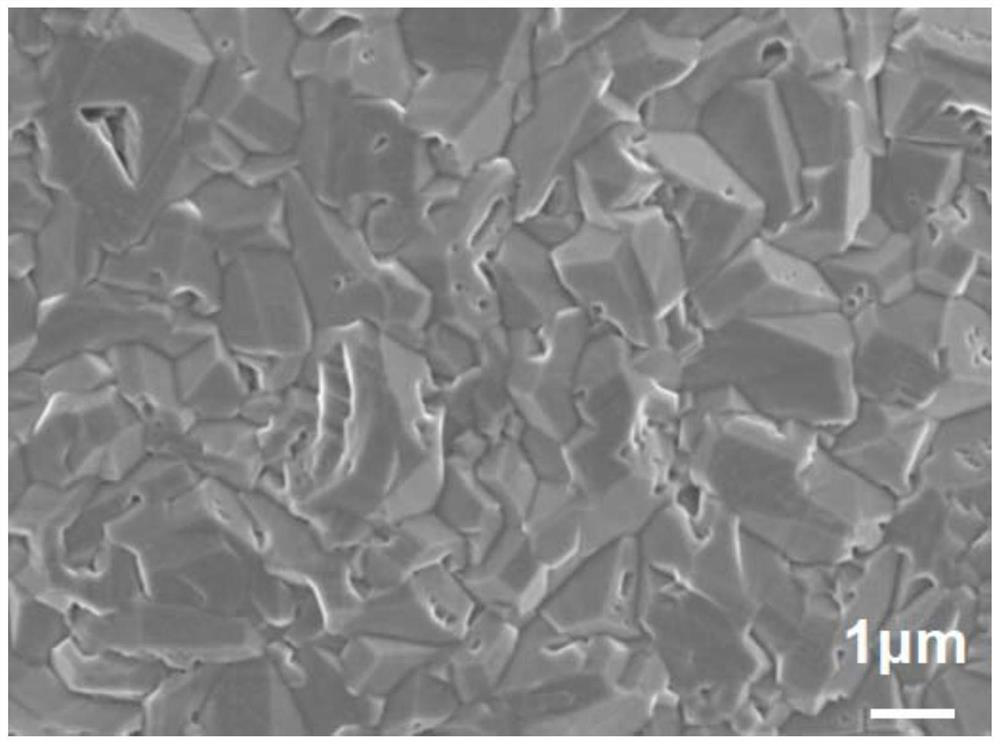

[0051] (c) Sintering the ferritic stainless steel connection body with the intermediate coating A on the surface in a reducing atmosphere, and then passing air into it to oxidize at a high temperature to obtain a manganese-cobalt spinel coating.

[0052] The preparation method of the manganese-cobalt spinel coating provided by the present invention, the preparation method first mixes the manganese-cobalt mixed powder with the solution to ob...

Embodiment 1

[0107] A kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0108] (1) Cut a flat ferritic stainless steel plate of appropriate size as a connecting body, and use 240, 800, and 2000 mesh sandpaper to polish and polish the front and back sides of the steel plate on a polishing machine until the surface roughness of the steel plate is <0.3 μm; Subsequently, the polished steel plates were ultrasonically cleaned in deionized water and absolute ethanol for 10 min to remove surface impurities and left to dry to obtain ferritic stainless steel joints;

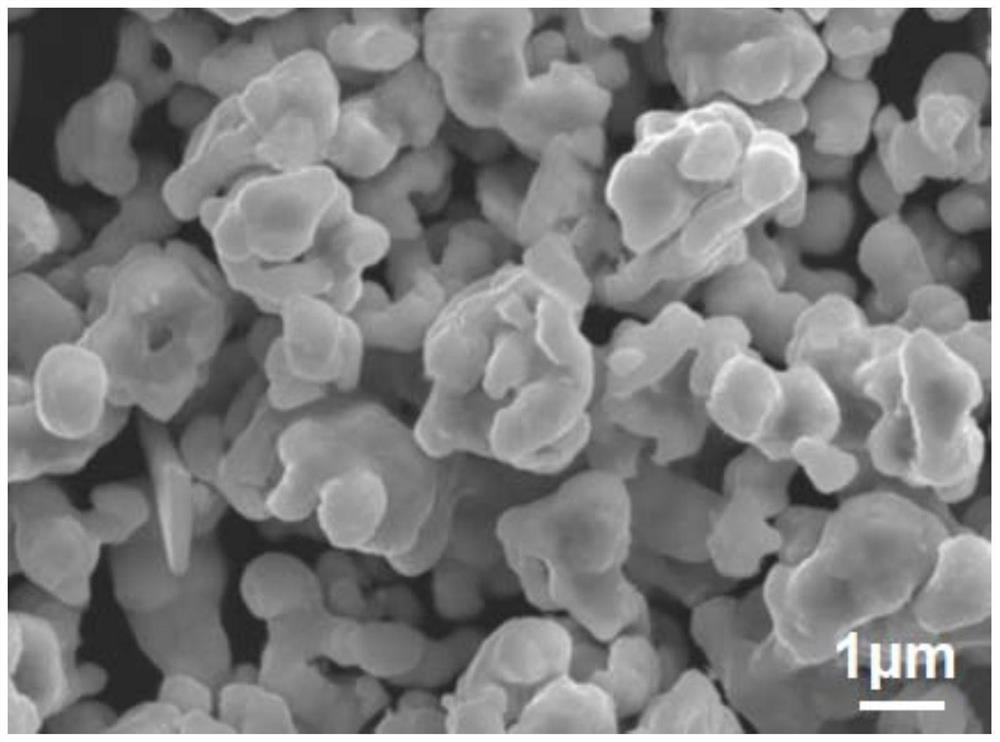

[0109] (2), mix manganese powder and cobalt powder with a mass ratio of 1.5:1.5, then add 2 times the mass of mixed powder in ethanol and mix to obtain a manganese-cobalt suspension; then mix the manganese-cobalt suspension in a ball mill Ball mill at a rate of not less than 180 rpm for more than 24 hours to prepare a suspension of manganese-cobalt powder that i...

Embodiment 2

[0119] A kind of preparation method of manganese-cobalt spinel coating, described preparation method comprises the following steps:

[0120] (1), with embodiment 1;

[0121] (2), mix manganese powder and cobalt powder with a mass ratio of 1.5:1.5, then add 2 times the mass of mixed powder in ethanol and mix to obtain a manganese-cobalt suspension; then mix the manganese-cobalt suspension in a ball mill Ball mill at a rate of not less than 100 rpm for more than 10 hours to prepare a uniformly mixed suspension of manganese-cobalt powder with a particle size of less than 2 microns. After the ball milling is completed, take out the suspension and place it at 40°C for 48 Hours of evaporation to remove the ethanol in the suspension to obtain dried and mixed manganese-cobalt mixed powder;

[0122] (3) Compound ethyl cellulose and terpineol at a mass ratio of 2:98 to obtain solution A; then mix the manganese-cobalt mixed powder in step (2) with solution A at a mass ratio of 1:1 , to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com