A kind of multi-layer solid electrolyte and its preparation method and lithium battery formed therefrom

A solid electrolyte and electrolyte technology, applied in the direction of non-aqueous electrolyte batteries, solid electrolytes, electrolytes, etc., can solve problems such as easy growth of lithium dendrites, achieve the effects of repairing cell tissue, buffering mechanical pressure, and reducing interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

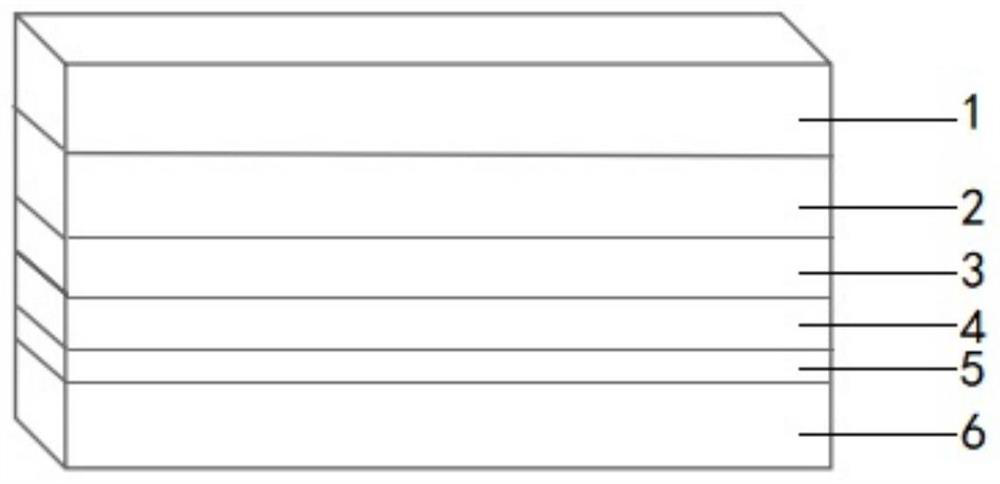

[0041] Dry the PEO in a vacuum oven at 50°C overnight, weigh 2.5mmol of PEO and dissolve it in 100mL of chloroform, and react at room temperature for 18h. Then pour it into 2L of ether, and PEO forms a precipitate and precipitates out. After the precipitate is separated by suction filtration, it is left to stand overnight in a fume hood, and then dried in a vacuum oven at 50°C for 5 hours to obtain a white cotton-like product of PEO. Weigh the white cottony product of PEO (—EO—) and lithium salt (LiTFSI), n(—EO—): n(Li + ) = 20:1, and heated to 80°C to melt the polymer completely, after mixing the two thoroughly by grinding, use a (hot press) tablet press to form a film at a pressure of 6 MPa and a temperature of 80°C and Cool and shape to obtain a uniform translucent solid electrolyte membrane with a thickness of 50 μm, that is, the supporting layer.

[0042] Using magnetron sputtering to sequentially construct lithium ion fast channel layer (LiPON layer), lithium dendrite s...

Embodiment 2

[0045] Dry the PEO in a vacuum oven at 50°C overnight, weigh 2.5mmol of PEO and dissolve it in 100mL of chloroform, and react at room temperature for 18h. Then pour it into 2L of ether, and PEO forms a precipitate and precipitates out. After the precipitate is separated by suction filtration, it is left to stand overnight in a fume hood, and then dried in a vacuum oven at 50°C for 5 hours to obtain a white cotton-like product of PEO. Weigh the white cottony product of PEO (—EO—) and lithium salt (LiTFSI), n(—EO—): n(Li + ) = 10:1, and heated to 80°C to melt the polymer completely, after mixing the two thoroughly by grinding, use a (hot press) tablet press to form a film at a pressure of 2 MPa and a temperature of 60°C and Cool and shape to obtain a uniform translucent solid electrolyte membrane with a thickness of 50 μm, that is, the supporting layer.

[0046] Using magnetron sputtering to sequentially construct lithium ion fast channel layer (LiPON layer), lithium dendrite s...

Embodiment 3

[0049] Dry the PEO in a vacuum oven at 50°C overnight, weigh 2.5mmol of PEO and dissolve it in 100mL of chloroform, and react at room temperature for 18h. Then pour it into 2L of ether, and PEO forms a precipitate and precipitates out. After the precipitate is separated by suction filtration, it is left to stand overnight in a fume hood, and then dried in a vacuum oven at 50°C for 5 hours to obtain a white cotton-like product of PEO. Weigh the white cottony product of PEO (—EO—) and lithium salt (LiTFSI), n(—EO—): n(Li + ) = 15:1, and heated to 80°C to melt the polymer completely, and after the two are thoroughly mixed by grinding, they are extruded into a film with a (hot press) tablet press at a pressure of 4MPa and a temperature of 70°C. Cool and shape to obtain a uniform translucent solid electrolyte membrane with a thickness of 100 μm, that is, the support layer.

[0050] Using magnetron sputtering to sequentially construct lithium ion fast channel layer (LiPON layer), l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com