A method for preparing glass-ceramic by using yellow phosphorus slag and chromium slag

A technology for yellow phosphorus slag and glass-ceramics, which is applied in the field of solid waste recycling, can solve the problems of high energy consumption, high production cost, less slag consumption, etc., and achieves the effects of simple production process, excellent performance, and reduced addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

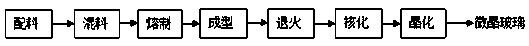

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing glass-ceramic by using yellow phosphorus slag and chromium slag described in this embodiment, the phosphorus slag produced when the yellow phosphorus is prepared by the electric furnace method and the chromium slag produced during the preparation process of the chromium salt sodium dichromate are the main raw materials , wherein the main components and mass percentage of yellow phosphorus slag are: SiO 2 37.28%, CaO46.08%, Al 2 o 3 3.22%, MgO2%; the main composition and mass percentage of chromium slag are: SiO 2 4.57%, Al 2 o 3 7.31%, CaO26.61%, MgO25.79%, Fe 2 o 3 11.55%, Cr 2 o 3 6.34%, the preparation process specifically includes the following steps:

[0022] (1) First crush the yellow phosphorus slag, chromium slag, quartz sand, fluorite, and coke, and screen the phosphorous slag, chromium slag, fluorite, and coke through a 40-mesh sieve. The particle size of the quartz sand is 60 mesh, and two The content of silicon oxide is 97%. W...

Embodiment 2

[0028] A method for preparing glass-ceramic by using yellow phosphorus slag and chromium slag described in this embodiment, the phosphorus slag produced when the yellow phosphorus is prepared by the electric furnace method and the chromium slag produced during the preparation process of the chromium salt sodium dichromate are the main raw materials , wherein the main components and mass percentage of yellow phosphorus slag are: SiO 2 35%, CaO49%, Al 2 o 3 5%, MgO1%; the main composition and mass percentage of chromium slag are: SiO 2 4%, Al 2 o 3 6%, CaO35%, MgO15%, Fe 2 o 3 12%, Cr 2 o 3 2.5%, the preparation process specifically includes the following steps:

[0029] (1) First crush the yellow phosphorus slag, chromium slag, quartz sand, fluorite, and charcoal, and screen the phosphorous slag, chromium slag, fluorite, and charcoal through a 40-mesh sieve. The particle size of the quartz sand is 80 mesh, of which two The content of silicon oxide is 98%. Weigh respect...

Embodiment 3

[0035] A method for preparing glass-ceramic by using yellow phosphorus slag and chromium slag described in this embodiment, the phosphorus slag produced when the yellow phosphorus is prepared by the electric furnace method and the chromium slag produced during the preparation process of the chromium salt sodium dichromate are the main raw materials , wherein the main components and mass percentage of yellow phosphorus slag are: SiO 2 45%, CaO43%, Al 2 o 3 3%, MgO1.8%; the main composition and mass percentage of chromium slag are: SiO 2 11%, Al 2 o 3 10%, CaO23%, MgO33%, Fe 2 o 3 7%, Cr 2 o 3 7.5%, the preparation process specifically includes the following steps:

[0036] (1) After crushing yellow phosphorus slag, chromium slag, quartz sand, fluorite and anthracite, the phosphorus slag, chromium slag, fluorite and anthracite are screened through a 40-mesh sieve, and the particle size of the quartz sand is 80 mesh, of which The silicon dioxide content is 97%, respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com