A kind of anti-corrosion paint resistant to high temperature wear and its preparation method and application

A technology for anti-corrosion coatings and high temperature resistance, applied in the direction of anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., to achieve good dispersion effect, avoid agglomeration, high density and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A high-temperature wear-resistant anti-corrosion coating, comprising the following raw materials in parts by weight:

[0040]100 parts of furan modified epoxy resin, 5 parts of epoxy polyether-polysiloxane, 20 parts of reactive diluent, 10 parts of filler, 0.4 parts of amino functional graphene, 3 parts of auxiliary agent, 3 parts of curing agent, 30 parts of solvent; the auxiliary agents are 1 part of coupling agent, 1 part of defoamer, and 1 part of dispersant;

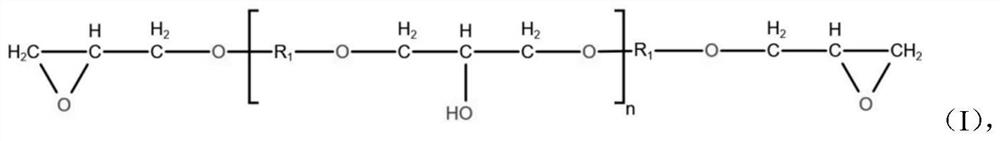

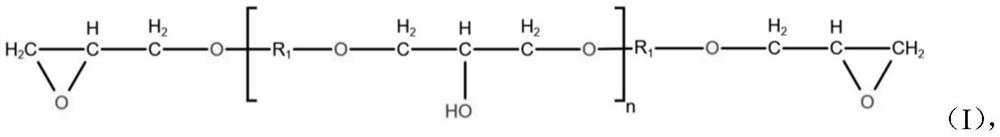

[0041] The furan-modified epoxy resin is prepared by mixing the furan-modified epoxy resins of formula (I) and formula (II) according to a weight ratio of 100:1;

[0042]

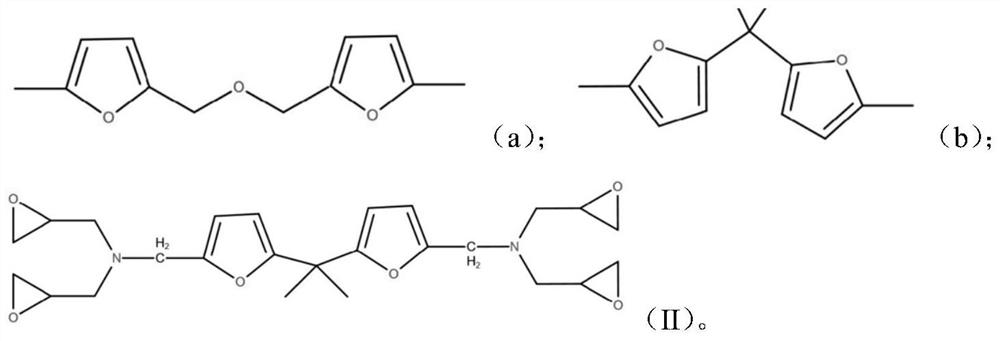

[0043] where n is 40 and R 1 is selected from the structure represented by formula (a):

[0044]

[0045] The epoxy polyether-polysiloxane is obtained by the following preparation method. The hydrogen-containing silicone oil and the epoxy-terminated allyl polyether are in a molar ratio (n(Si-H):n(C=C)) as Add 1:1.05 into the react...

Embodiment 2

[0052] A high-temperature wear-resistant anti-corrosion coating, comprising the following raw materials in parts by weight:

[0053] 100 parts of furan modified epoxy resin, 8 parts of epoxy polyether-polysiloxane, 30 parts of reactive diluent, 6 parts of filler, 0.5 part of isocyanate functionalized graphene, 5 parts of auxiliary agent, 4 parts of curing agent, 40 parts of solvent; the auxiliary agents are 0.5 part of leveling agent, 1 part of coupling agent, 1 part of defoamer, 1 part of dispersant, and 0.5 part of wetting agent;

[0054] The furan-modified epoxy resin is prepared by mixing the furan-modified epoxy resins of formula (I) and formula (II) according to a weight ratio of 100:0.5;

[0055]

[0056] where n is 60, R 1 is selected from the structure represented by formula (b):

[0057]

[0058] The epoxy polyether-polysiloxane is obtained by the following preparation method. The hydrogen-containing silicone oil and the epoxy-terminated allyl polyether are i...

Embodiment 3

[0066] A high-temperature wear-resistant anti-corrosion coating, comprising the following raw materials in parts by weight:

[0067] 100 parts of furan modified epoxy resin, 10 parts of epoxy polyether-polysiloxane, 30 parts of reactive diluent, 6 parts of filler, 0.6 part of amino functional graphene, 7 parts of auxiliary agent, 5 parts of curing agent, 50 parts of solvent; the auxiliary agents are 1 part of leveling agent, 2 parts of coupling agent, 2 parts of defoamer, 1 part of dispersant, and 1 part of wetting agent;

[0068] The furan-modified epoxy resin is formed by mixing the furan-modified epoxy resins of formula (I) and formula (II) according to a weight ratio of 100:1.5;

[0069]

[0070] where n is 55 and R 1 is selected from the structure represented by formula (a):

[0071]

[0072] The epoxy polyether-polysiloxane is obtained by the following preparation method. The hydrogen-containing silicone oil and the epoxy-terminated allyl polyether are in a molar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com