Lithium ion supercapacitor with positive electrode pre-embedded with lithium

A supercapacitor and pre-intercalated lithium technology, which is applied in the field of lithium-ion batteries, can solve the problems of difficult lithium-ion batteries, such as positive active materials and poor battery rate characteristics, to achieve improved rate cycle performance, high pseudocapacitance, and improved stability and the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

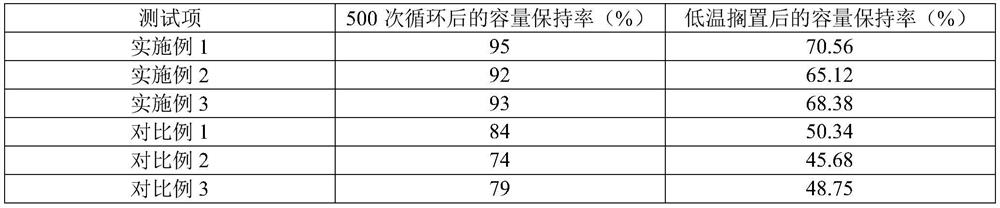

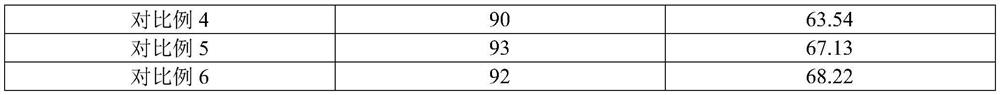

Examples

Embodiment 1

[0078] The positive electrode active material of the lithium-ion supercapacitor with the positive electrode pre-intercalated lithium is prepared according to the following steps:

[0079] (1) 150mg graphene oxide is dispersed in deionized water to obtain a dispersion of 5mg / mL;

[0080] (2) Add 1.5g spherical lithium iron phosphate precursor, 5mg Fe(NO 3 ) 3 9H 2 O, 15mg cobalt nitrate hexahydrate, 20mg thiourea, after stirring evenly, add 2mL formaldehyde, after stirring evenly, then add 650mg urea, stir until viscous resin;

[0081] (3) Place the above-mentioned viscous resinous mixture in a hydrothermal high-pressure reactor, and heat it under water for 8 hours at 120°C. After the reaction, freeze-dry the reaction product to obtain a loose and porous composite material;

[0082] (4) Calcining the composite material obtained in step (3) under an argon atmosphere at a calcination temperature of 700° C. and a calcination time of 2 h to obtain a positive electrode active mat...

Embodiment 2

[0084] The positive electrode active material of the lithium-ion supercapacitor with the positive electrode pre-intercalated lithium is prepared according to the following steps:

[0085] (1) 150mg graphene oxide is dispersed in deionized water to obtain a dispersion of 5mg / mL;

[0086] (2) Add 3g spherical lithium iron phosphate precursor, 5mg Fe(NO 3 ) 3 9H 2 O, 15mg cobalt nitrate hexahydrate, 20mg thiourea, after stirring evenly, add 2mL formaldehyde, after stirring evenly, then add 750mg melamine, stir until viscous resin;

[0087] (3) Place the above-mentioned viscous resinous mixture in a hydrothermal autoclave, heat at 120°C for 24 hours, and after the reaction, freeze-dry the reaction product to obtain a loose and porous composite material;

[0088] (4) Calcining the composite material obtained in step (3) under an argon atmosphere at a calcination temperature of 700-800° C. and a calcination time of 3 hours to obtain a positive electrode active material.

Embodiment 3

[0090] The positive electrode active material of the lithium-ion supercapacitor with the positive electrode pre-intercalated lithium is prepared according to the following steps:

[0091] (1) 150mg graphene oxide is dispersed in deionized water to obtain a dispersion of 5mg / mL;

[0092] (2) Add 2g spherical lithium iron phosphate precursor, 5mg Fe(NO 3 ) 3 9H 2 O, 15mg cobalt nitrate hexahydrate, 20mg thiourea, after stirring evenly, add 2mL formaldehyde, after stirring evenly, then add 700mg melamine, stir until viscous resin;

[0093] (3) Place the above-mentioned viscous resinous mixture in a hydrothermal high-pressure reactor, and heat it under water for 12 hours at 120°C. After the reaction, freeze-dry the reaction product to obtain a loose and porous composite material;

[0094] (4) Calcining the composite material obtained in step (3) under an argon atmosphere, the calcination temperature is 750° C., and the calcination time is 2.5 h, to obtain the positive electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com