A preparation method of nano-micro graded manganese phosphate lithium/carbon composite positive electrode material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

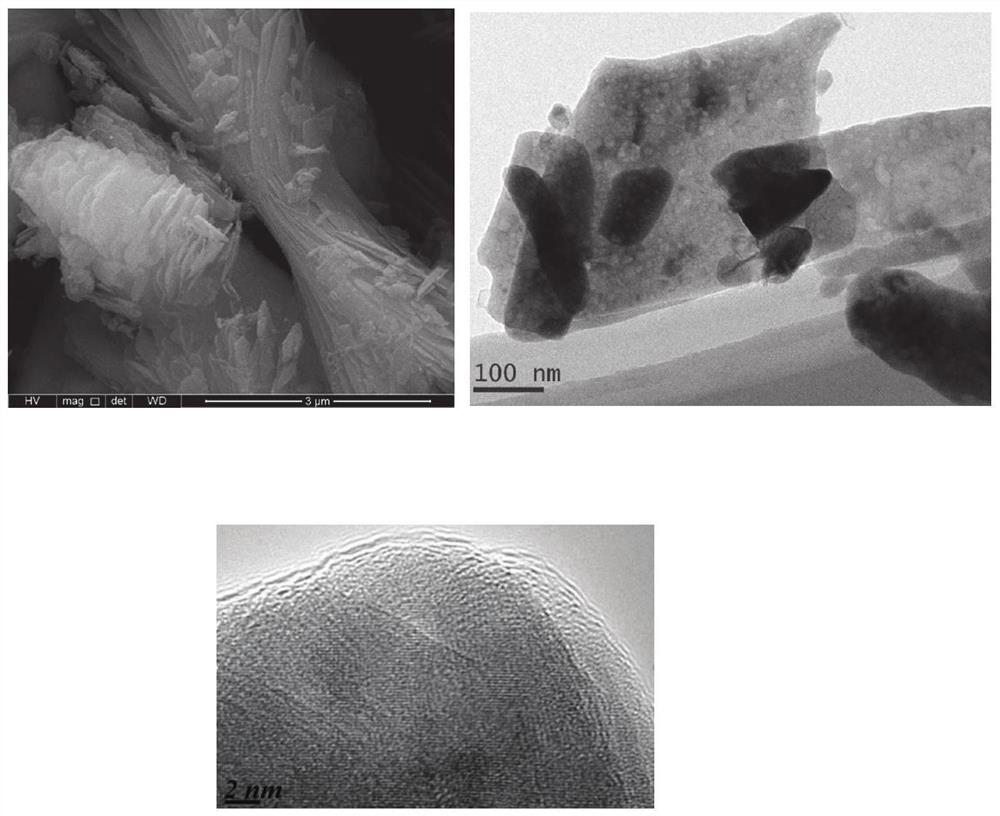

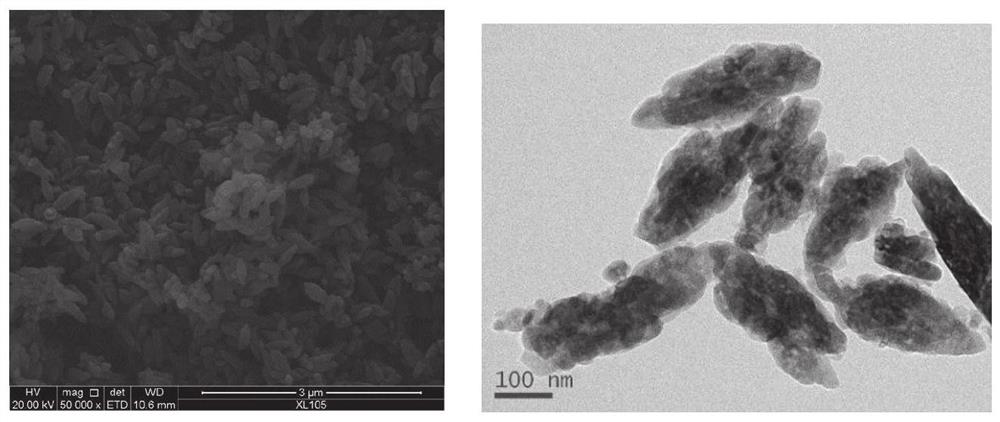

Image

Examples

Embodiment 1

[0064] Fixed stoichiometric ratio Li:Mn:P:HMT=2.7:0.95:1:1.2, weighing 0.054mol lithium nitrate, 0.019mol manganese sulfate, 0.02mol phosphoric acid (85%) and 0.024mol hexamethylenetetramine, the nitric acid Lithium, manganese sulfate and hexamethylenetetramine were respectively dissolved in 20ml of ethylene glycol to obtain lithium nitrate solution, manganese sulfate solution, phosphoric acid solution and hexamethylenetetramine solution, heated and stirred at 35°C for 20min; into the manganese sulfate solution being stirred, then drop the lithium nitrate solution into it, and finally drop into the hexamethylenetetramine solution solution, stir sufficiently to finally obtain a mixed emulsion; the emulsion slurry is transferred to a 180ml high-pressure reactor, Place the autoclave in an oven for 1 hour at 80°C and 180°C for 10 hours. After cooling, take out the autoclave, centrifuge the slurry, wash the reactant twice with deionized water and absolute ethanol, and place the wash...

Embodiment 2

[0067]With the metering ratio Li:Mn:P:HMT=3:1:1:1.7, weigh 0.06mol lithium chloride, 0.02mol manganese chloride, 0.02mol phosphoric acid (85%) and 0.034mol hexamethylenetetramine, Dissolve lithium chloride, manganese chloride tetrahydrate and hexamethylenetetramine in 20ml of ethylene glycol respectively to obtain lithium nitrate solution, manganese chloride solution, phosphoric acid solution and hexamethylenetetramine solution; heat at 40°C Stir for 30 minutes; drop the phosphoric acid solution into the manganese chloride solution being stirred, then drop the lithium chloride solution into it, and finally drop into the hexamethylenetetramine solution, stir for 50 minutes to obtain a mixed emulsion; transfer the emulsion to 180ml of high-pressure Reactor, put the high-pressure reactor in an oven for 2 hours at 75°C, and keep it at 160°C for 12 hours. After cooling, take out the high-pressure reactor, centrifuge the slurry, and wash the reactants twice with deionized water and a...

Embodiment 3

[0070] Weigh 0.06 mol of lithium nitrate, 0.019 mol of manganese nitrate (50%), 0.02 mol of lithium dihydrogen phosphate and 0.02 mol of hexamethylenetetramine at the metering ratio Li:Mn:P:HMT=3:0.95:1:1, Lithium nitrate, manganese nitrate and hexamethylenetetramine were dissolved in 20ml of ethylene glycol, and lithium dihydrogen phosphate was dissolved in 30ml of deionized water to obtain lithium nitrate solution, manganese nitrate solution, lithium dihydrogen phosphate solution and hexaethylene tetramine respectively. Methyltetramine solution. Add the lithium dihydrogen phosphate solution dropwise into the stirring manganese nitrate solution, then drop the lithium chloride solution into it, and finally drop into the hexamethylenetetramine solution, and stir for 30 minutes to obtain a mixed emulsion; the emulsion is transferred to a high-pressure 180ml Reactor, put the autoclave in an oven at 70°C for 1 hour, and at 200°C for 10 hours. After cooling, take out the autoclave,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com