Cellulose inorganic composite membrane, high-temperature-resistant battery diaphragm as well as preparation method and application of high-temperature-resistant battery diaphragm

An inorganic composite membrane and battery separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as affecting battery cycle life and safety performance, battery rate performance, poor thermal stability of separators, affecting battery safety performance, etc. , to achieve the effect of favorable wetting and ion migration, excellent physical and electrochemical properties, and improved long-term shelving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for preparing a filling powder material for a high-temperature-resistant battery separator, wherein the preparation method includes the following steps:

[0054] Weigh 1g sodium alginate and add it to 100mL deionized water, stir and dissolve to a clear solution;

[0055] Weigh 2g of diatomaceous earth, dry in vacuum at 120°C for 12 hours, and then cool down naturally;

[0056] Add the dried diatomaceous earth to the above-mentioned sodium alginate solution, stir for 12 hours, and filter with suction;

[0057] The above powder was vacuum dried at 120° C. for 12 hours, and then ground to obtain a filling powder material for a high temperature resistant battery diaphragm.

Embodiment 2

[0059] This embodiment provides a method for preparing a filling powder material for a high-temperature-resistant battery separator, wherein the preparation method includes the following steps:

[0060] Weigh 2g sodium alginate and add it to 100mL deionized water, stir and dissolve to a clear solution;

[0061] Weigh 2g of diatomaceous earth, dry in vacuum at 120°C for 12 hours, and then cool down naturally;

[0062] Add the dried diatomaceous earth to the above-mentioned sodium alginate solution, stir for 12 hours, and filter with suction;

[0063] The above powder was vacuum dried at 120° C. for 12 hours, and then ground to obtain a filling powder material for a high temperature resistant battery diaphragm.

Embodiment 3

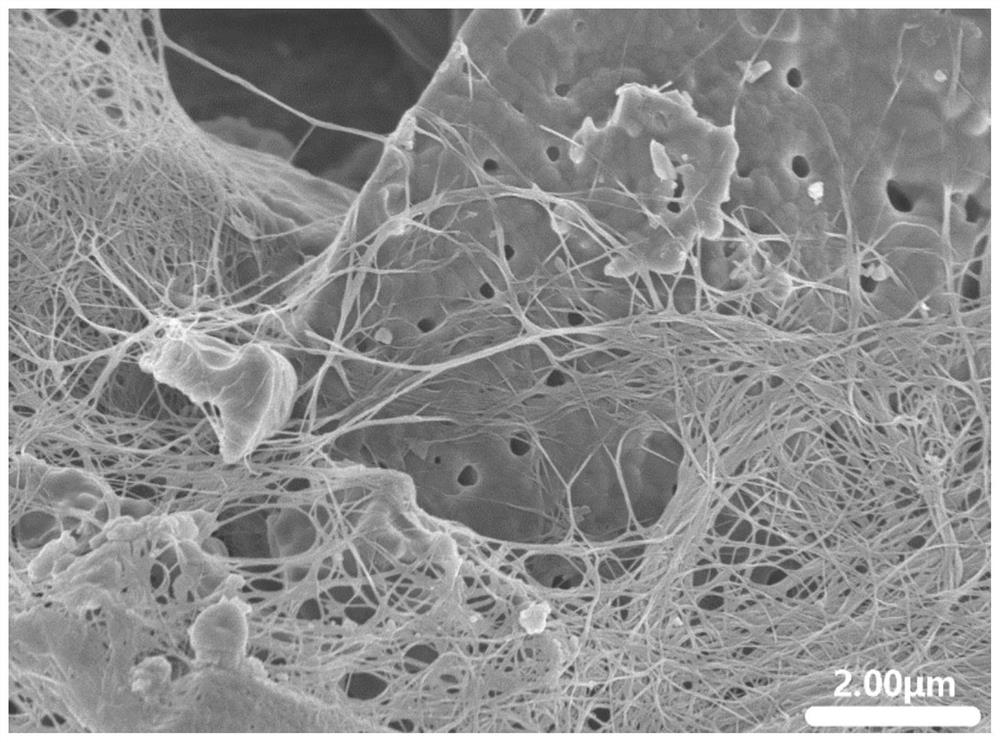

[0065] This embodiment provides a method for preparing bacterial cellulose fibers for a high-temperature-resistant battery separator, wherein the preparation method includes the following steps:

[0066] Shred the bacterial cellulose taken out of the refrigerator, put it into 400 mL of water and ethanol with a volume ratio of 1:1 for cleaning, stir for 24 hours, and change the mixed solution every 8 hours for 3 times.

[0067] Put the above-mentioned cleaned bacterial cellulose into a 500mL round bottom flask filled with 300mL1mol / L sodium hydroxide solution, purify it in an oil bath at 60°C for 6 hours, and then mix it with water and ethanol at a volume ratio of 1:1. The solution was washed to neutral.

[0068] Continue to put the above-mentioned neutral bacterial cellulose into 400 mL of water and ethanol with a volume ratio of 1:1 for cleaning, stir for 24 hours, and change the mixed solution every 8 hours for 3 times.

[0069] The above-mentioned bacterial cellulose was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com